& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

The digital transformation process aligns modern technology and digital resources to all business needs and goals. Digital transformation is generally an ongoing, long-term journey in which automated processes and digital solutions like CAD software begin to replace outdated technologies. In their more advanced stages, digital transformations break down departmental silos with cloud-connected platforms specialized for industry-specific needs. These platforms tie together people and processes by collecting constant streams of data and centralizing them in a single source of truth available to all stakeholders in real time.

As one of the ultimate benefits of digital transformation, artificial intelligence (AI) derives valuable insights from the collected data to inform decision making. Successful digital transformations lower costs over time, improve customer experience, and lead to innovative new business opportunities.

The potential benefits of digital transformation touch every part of a product, project, or building lifecycle, from early design all the way to the customer experience.

Digital transformation can automate processes and streamline operations to make production more efficient and equip businesses to adapt quickly to changing business conditions, customer demands, and emerging opportunities.

Adopting digital technologies can help teams innovate new offerings, business models, and workflows faster. Generative design quickly delivers thousands of smart solutions according to designers’ and engineers’ criteria, while generative scheduling saves untold hours organizing production tasks.

With digital transformation technologies, vendors can provide their customers with more personalized products and services, as well as more responsive customer communication. All of this helps to strengthen customer loyalty and satisfaction.

Many advanced digital tools, from extended reality (XR) technology to cloud-connected software platforms, allow team members to communicate better and collaborate seamlessly, regardless of where they’re located.

Key to the digital transformation process is the pervasive collection and analysis of product and process data. With powerful, AI-driven data analysis, businesses gain valuable insights that inform crucial decisions on optimizing strategies and predicting trends.

The tools and solutions used in a corporate digital transformation can be implemented on a smaller, pilot basis and then easily scaled up to support additional departments, new ventures, or the entire enterprise.

Digital transformation is vital because change cycles in Design and Make industries have accelerated faster than ever before. Some industry leaders see digital transformation as a way to stay ahead of this steep change curve, while others see it as a minimum requirement to survive in the modern competitive landscape.

There are many important advantages to digital transformation. By automating processes, it can streamline operations and increase overall efficiency. It also helps businesses adapt faster to rapidly changing markets, supply chain conditions, and customer needs. This agility can tighten the bonds of customer loyalty, and data-based insights from digital tools can also improve customer experience.

Digital transformation also fosters a culture of innovation. Even when an innovative spirit is the norm in an organization, adding the powerful tools of a digital transformation boosts innovative capabilities and opens up new revenue streams and business models. Organizations that embrace modern digital capabilities more nimbly respond to the ever-present changes in business and can gain a competitive advantage over those slower to adapt.

While digital transformations can reward businesses handsomely, they also carry some degree of risk. Merely implementing new technologies and processes isn’t enough; progress should be monitored and quantified continuously. Determine which metrics and KPIs indicate success in advance, then adjust them as the digital transformation plays out. Appropriate measurements will likely fall into the categories of financials, workforce, and change management.

Financials such as revenue growth, margins, operational efficiencies, and lifetime customer value are relatively straightforward KPIs. However, companies should pay close attention to the human side of digital transformation by monitoring whether impacted teams are staffed sufficiently and are adopting modern workflows along with modern technology, such as agile product development and data-based user-experience design. Change-management factors can be compared against the company’s initial plans and goals. For example, are teams adapting to the changes and developing new abilities at the desired pace? Are employees engaged and using the new technologies and tools comfortably?

Effectively measuring these aspects of digital transformation helps leaders manage performance and change course in a timely manner if needed.

Building information modeling (BIM) and artificial intelligence (AI) drive digital transformation in the AECO industry. BIM creates data-rich digital representations of assets that produce better outcomes for businesses and the built environment, while AI is becoming a vital partner in assisting human creativity.

A connected data platform is crucial for design and manufacturing companies to enable more dynamic collaboration between departments and roles. It also helps to enable process streamlining and automation, and to converge disciplines like CAD, CAM, CAE, PLM (product lifecycle management), and MES (manufacturing execution systems) into a single, AI-assisted digital environment.

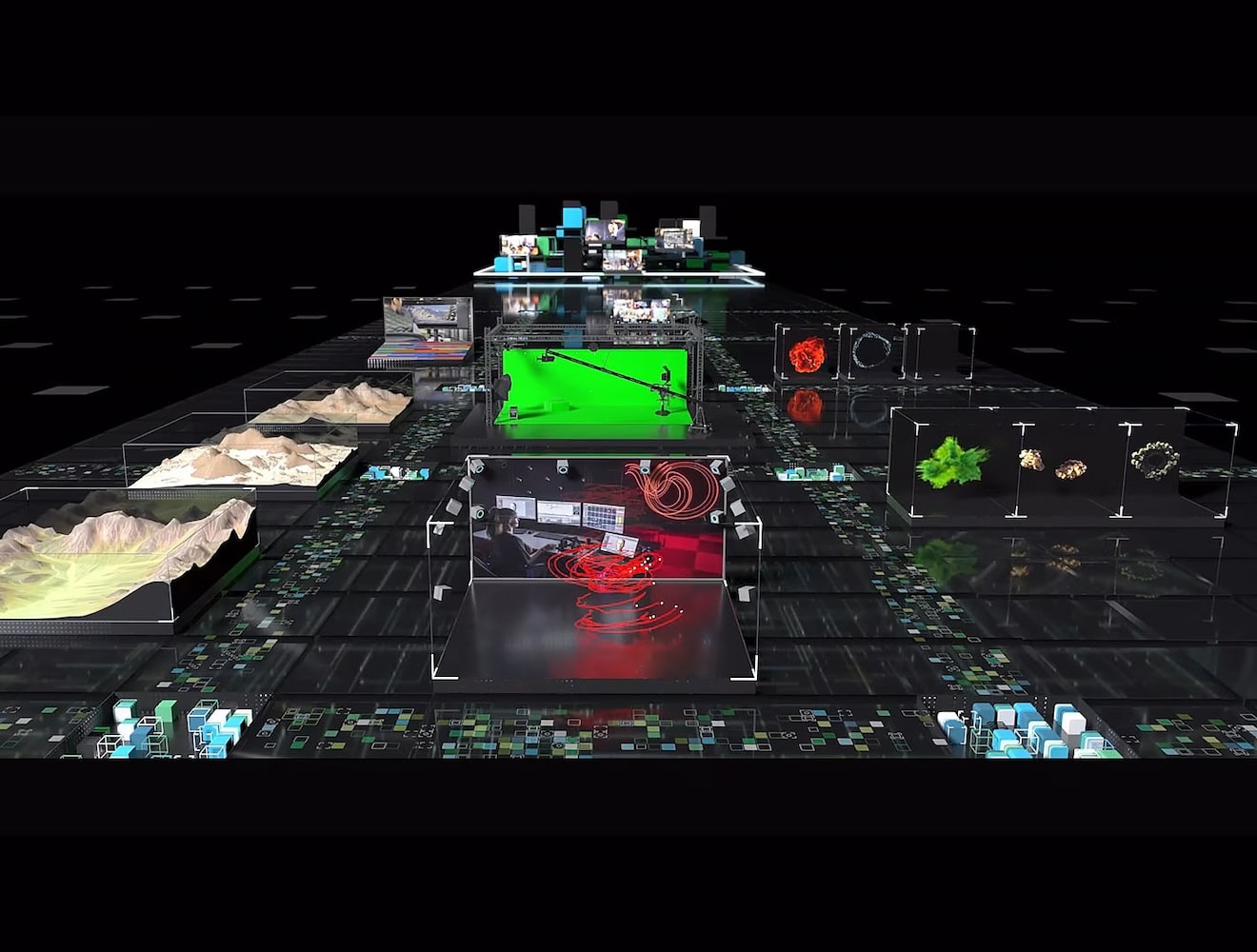

Digital transformation in media and entertainment helps to connect people, workflows, and data across the entire production lifecycle, from a script’s earliest concept to the final product. It allows greater benefits from technologies like AI, real-time workflows, third-party pipeline integrations, industry standards, and asset concurrency.

Across all Design and Make industries, a confluence of important technologies drives the hallmarks of digital transformation: improved productivity, innovation, and customer experience.

Near the top of that list of technologies are different forms of artificial intelligence (AI), including generative AI and machine learning. AI powers predictive analytics, which can anticipate disruptions to the supply chain and adjust accordingly or calculate predictive maintenance for machinery to avoid downtime. AI helps to automate processes, whether that’s the robotic finishing of drywall on a building site or the automated media production scheduling that dynamically updates any changes. AI chatbots, for example, provide customer service, while internal AI’s data analysis improves informed decision making.

Big data and analytics are paramount to a digital transformation, and the Internet of Things (IoT) enables the constant and pervasive data collection that fuels pattern discovery and insights revealed by AI data analytics. Whether it’s the IoT data from building sensors that feed into a BIM digital twin or the assembly line machine data that powers a smart factory’s operation, IoT devices connect real-time operations data to the cloud for near-instant metrics and insights.

Pairing all that data with cloud computing is a must for digital transformation. A cloud platform centralizes all data insights in a single place, empowering employees to collaborate well with teammates around the world.

All of these technologies connect entire work ecosystems together, from automated processes to teammates and vendors working seamlessly together, so that businesses can do their work faster, more efficiently, and more collaboratively, and make better products while producing less waste.

Essentially, a digital transformation should begin with the end game. Before doing anything else, define a clear set of tangible goals you want your digital transformation to meet over the next one or more years. Each goal should address a particular challenge and result in a beneficial business outcome. A manufacturer may want to reduce downtime by upgrading to assembly line machines that collect constant data and utilize AI-driven predictive maintenance. An AECO firm may wish to streamline operations by making full use of BIM data and digital twins. And a media and entertainment studio may want to focus its staff’s attention by adding generative scheduling that dynamically updates when changes occur.

Whatever the goals, plan for their implementation by breaking them into small, definable steps. Each step should end in a valuable milestone that addresses a desired business outcome, such as additional revenue, higher productivity, or better customer experience, loyalty, and retention. Any newly introduced technologies must also measurably improve upon the workflows and operations they replace.

With the plan set, present it to both executive and non-executive teams. Any organization’s leadership must support a digital transformation plan to set it up with the resources and top-down workplace cultural shifts needed. Non-executive team members will also need to support the transformation, as well as potentially requiring new training and skills.

These digital transformation examples show how businesses can radically improve their efficiency, find new revenue streams, and more.

VISICONSULT

VisiConsult X-ray Systems & Solutions’ digital transformation opened up new avenues of business. Its use of digital twins, AI, and cloud collaboration allowed it to branch off into subscription digital services in X-ray images and image interpretation. Its use of Autodesk Fusion Manage PLM software reduced paper waste and overall time to market due to streamlined processes.

Image courtesy of Chris Mueller

PM GROUP

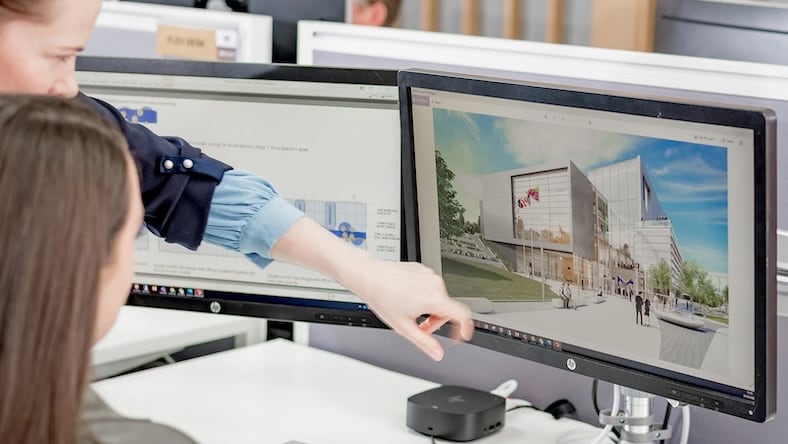

Digital transformation technologies require the right quality and quantity of people to use them. International project delivery specialist in the AECO sector PM Group focuses on attracting and cultivating talent that thrives on cloud-based collaboration by promoting work/life balance, mental wellness, and effective communication.

Image courtesy of PM Group

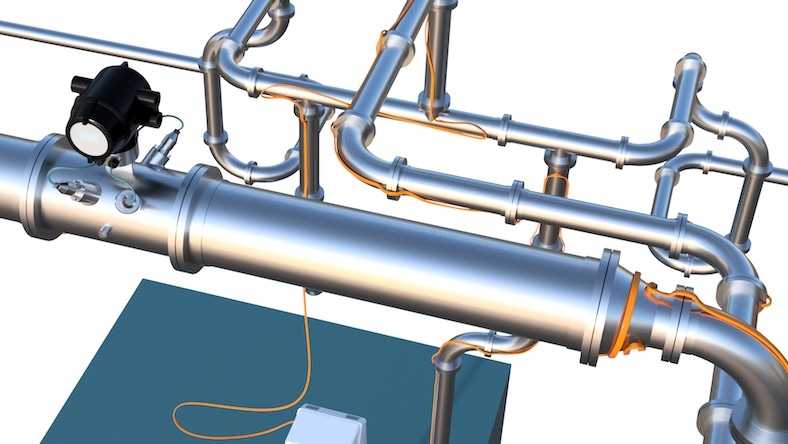

THERMOTEX ENGINEERING

This UK manufacturer of bespoke heat-tracing and insulation products transitioned away from paper-based processes using Autodesk software to centralize data management and enhance compliance. Thermotex’s digital transformation improved efficiency and allowed it to grow by launching a consultancy wing.

Image courtesy of Thermotex

Technological progress and the forces of modernization are all leading inexorably to digital transformation for Design and Make businesses. Digital transformation equips companies with the agility they need to adapt to the changes that—faster than ever before—are altering products, production, services, and customer expectations.

Digital transformation begins with convergence, connecting your organization using data while bridging the gap to bring together different disciplines such as CAD, CAM, or CAE, and different teams in one cloud-computing environment.

Data is the key to connecting your entire business ecosystem and keeping your business operational. Accessing data via the cloud has become a necessity for collaboration; it’s a critical component that connects end to end, from initial concept to delivery to your customers.

Automation eliminates the delays of manual work. With automation tools like generative design, you can streamline and accelerate multiple processes across all departments while supporting increased innovation and creativity.

In this quick video, Autodesk CEO Andrew Anagnost explains how important the AI component is to today’s digital transformations in the Design and Make industries.

The design and manufacturing industry manager at Autodesk speaks on how a digital transformation can take a business stretched to the breaking point and deliver better business and sustainability outcomes with changes like switching to cloud-based, connected collaboration technology.

This Autodesk University video class focuses on strategizing and implementing digital transformation solutions for AECO businesses. Save time and money by aligning technology to current needs and future goals.

The 2024 State of Design & Make report from Autodesk shows key themes for the design and manufacturing, AECO, and media and entertainment industries that are making them more optimistic than in 2023. Those themes include their level of digital transformation, resilience, preparedness, and performance.

Hear from a panel of cross-industry experts about how digital transformation accelerates sustainable design and sustainable construction by enabling data-based decision-making.

The latest digital transformation trends in manufacturing include agile supply chains and advancements in robotics, AI, and collaboration tools that make the digital factory more intelligent, adaptable, and interconnected.

Digital transformation comprehensively overhauls a business’s operations, strategies, and culture by aligning digital technologies and data with business needs and goals. Digital transformation is generally an ongoing, long-term effort to optimize efficiencies and customer experiences.

In a digital transformation, outdated and siloed technologies are replaced with, for example, automated processes and cloud-connected software platforms that collect constant streams of data and use AI to derive valuable insights that inform decision making. This more transparent and intelligent way of working fosters innovation, leading to new business opportunities and breakthroughs.

A digital business transformation is conceptually a little less broad than a digital transformation. In a digital business transformation, a company adopts digital technologies specifically to optimize revenue streams and business processes and to improve the customer experience.

Digital transformation is important to stay competitive in the modern marketplace. It helps firms adapt to changing market conditions such as supply chain disruptions and shifts in customer demands. Digital transformation technologies can lead to new insights into customer behavior while also making the customer experience better and more personalized.

The crucial benefits of digital transformation also include overall better efficiency and a fertile ground for innovation, often resulting in new business models and revenue streams.

Once an organization decides to move past “business as usual,” the stages of digital transformation include “present and active,” where early adopter change agents experiment with new possibilities. In the next stage, the digital transformation becomes “formalized” within the company and there’s a sense of urgency to modernize.

When the digital transformation becomes a priority, the company gets “strategic” by road-mapping specific short- and long-term goals leading to key outcomes. In the next stage, the business is fully “converged” on the digital transformation effort—unifying roles and processes, streamlining operations, and deploying technology purposefully. The final stage is an ongoing culture of innovation as technology and business conditions evolve.

Digital transformations take various lengths of time depending on how ambitious the project is and the size of the organization. For small and medium enterprises, a modest digital transformation may take a year to a year and a half, or double that time for a larger project. At large enterprises where organizations are more complex, experts suggest that a minimal digital transformation could take one and a half to two years. However, digital transformations are also considered ongoing journeys that continue well past when a company becomes digitally mature, evolving along with changing technologies and market conditions.

The key drivers of digital transformation include technology, the competitive landscape, and people’s expectations. First, advanced technologies like cloud computing, AI-powered big data analysis, the Internet of Things (IoT), and others create efficiencies, enable data-based decision making, and make it easier to manage increasingly globalized operations. The resulting need for cybersecurity is another driver. Both customers and employees drive digital transformation too, as they expect businesses to offer the latest digital productivity tools and the kind of personalized customer experiences that digitally transformed companies can offer.

Digital transformations can fail when there is not enough strategy and organization behind them. For a digital transformation to succeed, a company should first develop a clear vision and set of desired business outcomes to achieve, and it should have the backing of top executives and leaders, who need to allocate the proper resources.

Employees should be prioritized over the new technology and may require training and other support to embrace the new changes; inadequate training and support for employees can undermine digital transformation efforts. Finally, poor integration of the new technology and a failure to swiftly adapt the plan according to market conditions can also cause a digital transformation to fail.