& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Sporting goods manufacturing and design is an area of product development particularly centered around factors of product performance, durability, and fine-tuned dimensional and material details. As such, it greatly benefits from design software’s more precise and more accurate 3D modeling, the cost-saving dependability of software simulation, and the data centralization and collaboration enabled by cloud connectivity.

Sporting goods design has always had to meet stringent demands for product performance, durability, and the fine-tuning of sizes, materials, and other factors to suit different conditions and fit athletes of all sizes and abilities. Modern sporting goods design also has to consider the urging from customers and governments to make products more sustainable, which includes using recycled and recyclable materials, using less material and energy in the design and manufacturing processes, and making the supply chain more efficient.

Fortunately for sports goods manufacturers, advanced design and manufacturing software has tools built in to address these concerns and to reduce errors, cost, and time spent while enhancing sustainability and collaboration across teams. At the initial product conceptualization stage, design software offers 2D and 3D sketching for fleshing out ideas and visualizing early concepts.

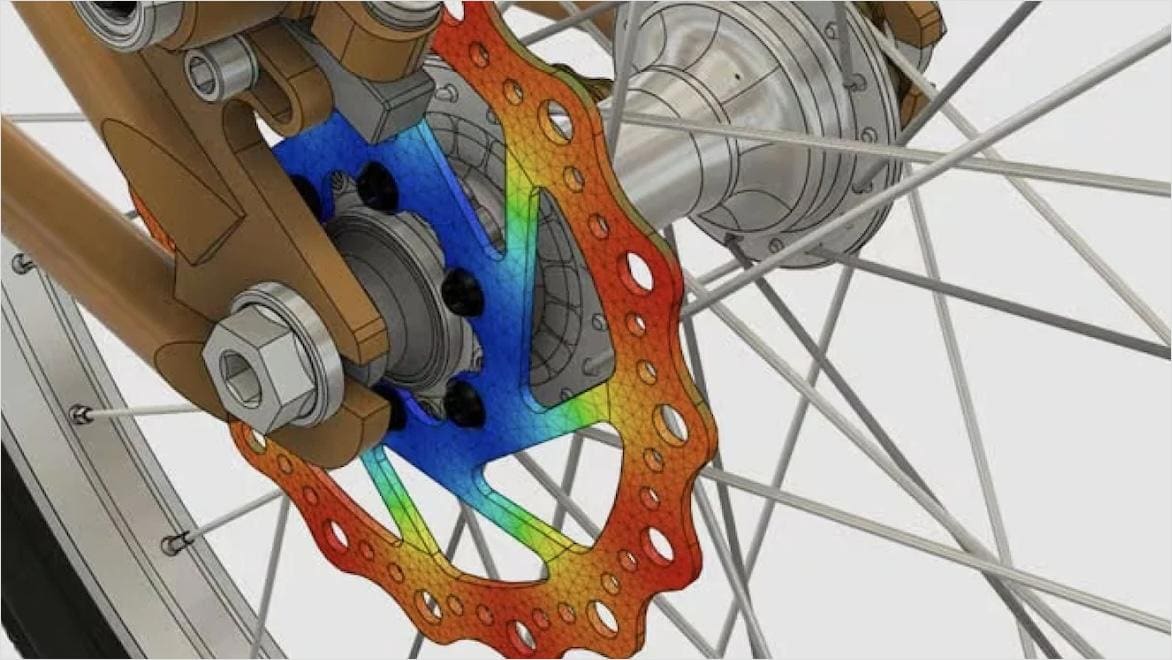

When it’s time to further solidify the product’s form and functionality, CAD software enables more accurate 3D modeling and more precise design adjustments. Some CAD software, like Autodesk Inventor, also includes onboard simulation for testing models’ response to real-life conditions such as dynamic motion simulation and finite element analysis (FEA) for stresses like heat, pressure, and impacts.

Simulated testing and photorealistic 3D visualization in CAD software can reduce the need for physical prototypes. However, when it’s time to build prototypes for real-world testing, Autodesk Fusion CAD software also includes CAM (computer-aided manufacturing) abilities for setting up manufacturing on CNC machines, 3D printers, and other machines with functions like automatic toolpaths and automatic data translation.

At every stage of sporting goods manufacturing, software plays a crucial role in expediting the process and ensuring the most precise and reliable results. For example, sports equipment depends greatly on high-quality materials that will promote the long life and proper performance of the product. Autodesk’s design and manufacturing software offers material selection options that inform manufacturers of the material’s physical properties, as well as other factors like the material’s impact on sustainability, cost, and supply chain logistics.

Modern methods for advanced manufacturing can also help reduce production errors while increasing the efficiency and output of manufacturing systems. Whether that entails assembly lines utilizing robotics automation or computer-controlled equipment like 3D printers, laser cutters, and other CNC machines, software helps to set up and manage these processes, while analyzing data collected from the manufacturing systems to further optimize production. Manufacturing execution systems (MES) software, such as Fusion Operations, monitors and manages factory production processes.

Software also comes into play for quality assurance and control, as well as inventory management. AI and the sensor technology of Industrial Internet of Things (IIoT) devices can automate with impressive accuracy certain aspects of quality inspections and inventory control, feeding data into software to derive insights that can inform decisions on improving a product’s design, its manufacturing process, or its supply chain. Product lifecycle management (PLM) software, such as Fusion Manage, centralizes all product data in one place for a product’s entire lifecycle, from brainstorming to end-of-life recycling or disposal.

Introducing advanced software into sporting goods manufacturing and design confers comprehensive benefits on the process, saving resources while also leading to higher quality, more innovative products.

Sports equipment designers can indulge their creativity by exploring endless combinations of features, materials, surfaces, and more using CAD software. The addition of generative design extends the innovative possibilities beyond the scope of human designers.

Advanced CAD software offers enhanced accuracy and more precision in 3D modeling. This helps sporting goods manufacturers achieve excellent product reliability by reducing assembly and functionality errors.

In addition to 3D CAD modeling computer-aided engineering (CAE), Autodesk Fusion bundles computer-aided manufacturing (CAM) with functions like automatic toolpaths and automatic data translation, so teams can move seamlessly from designing to making physical prototypes in one software program.

Cloud-connected design and manufacturing software from Autodesk breaks down departmental silos by providing an up-to-the-moment single source of truth for product data. Every stakeholder involved with the project can collaborate from any location, leading to better-informed decision making and communication.

Autodesk’s CAD software delivers stunning 3D visualization capabilities for conveying realistic design intent for reviews and presentations, while its powerful simulation functions allow sports goods manufacturers to perform stress tests and functionality tests virtually, before moving to physical prototyping.

Decreasing the need for physical prototypes reduces product development costs, while more streamlined workflows and the automation of tedious tasks can also accelerate sports equipment design iterations.

DECATHLON

Leading European sporting goods manufacturer and retailer Decathlon explored the possibilities for a more sustainable diving fin using Autodesk Fusion’s generative design and simulation tools. The impressive results halved the fin’s material usage and carbon footprint while using recycled materials that are themselves recyclable.

Image courtesy of Decathlon

O’NEAL

For its new motocross and mountain biking helmet, O’NEAL designed electronics and sensors in the back of the helmet that detect serious crashes and alert first responders with the rider’s location. Using Fusion’s cloud-based collaboration and rapid prototyping functionality, O’NEAL estimates it cut development time from 24 months to six months.

WNDR ALPINE

Spinoff company WNDR Alpine was launched to create skis free of fossil fuels using a novel biobased polyurethane made from microalgae oil. The team used Fusion’s CAD and CAM capabilities to quickly iterate versions of the product, designing, producing, and testing iterations all in a couple of days.

Learn how mass customization features in software can save you time when creating multiple variations of sports equipment designs—for example how PEMBREE used Fusion to make many variations of its 99.9% recyclable bicycle pedals.

One industrial designer started an open-source mountain bike project, which, due to its modularity and adaptability, has led to versions of the bike being built across multiple continents. Find out how in this Autodesk University presentation.

Autodesk Fusion software is equipped with generative design AI, which lets sports goods manufacturers parse thousands of production-ready design options to find and optimize the best ones, like how SRAM used generative design to reinvent its bicycle crankarm.

France’s leading sporting goods manufacturer and retailer, Decathlon, uses generative design in software to reduce the environmental impact of thousands of its products. Learn how in this Autodesk University video presentation.

Discover how companies develop products from start to finish in the 3D digital realm with 3D manufacturing, like Delfast, which accelerated the production cycle of its electric bike from a year to three months.

Composite materials are very popular for sports equipment manufacturing because of their potential for high strength- and stiffness-to-weight ratios. Learn how to run complex composite material simulations using software in this Autodesk University video class.

The future of the sporting goods manufacturing industry is bright as people continue to be more health- and fitness-conscious. They’re exercising and playing sports more and favoring sports that are social and easy to learn, such as pickleball. People are also demanding more sustainable products that use greener materials and production practices, as well as innovative products with advanced ergonomics and smart technology like biometric monitoring.

Companies can keep up with these trends through digital transformation—basing their design, production, distribution, and sales systems on the latest technology that enables rapid innovation, smart manufacturing, advanced data analytics, personalized marketing, and more.

Software is used in sporting goods manufacturing from the earliest design phase all the way through to supply chain management and customer support. For example, advanced CAD software supports more precise 3D modeling and simulation testing that makes rapid prototyping iterations faster and more innovative.

MES software, such as Fusion Operations, monitors and manages factory production processes. And PLM software, such as Fusion Manage, centralizes all product data in one place for a product’s entire lifecycle, from brainstorming to end-of-life recycling or disposal.

Sporting equipment is designed with software thanks to a variety of helpful functionality. Advanced CAD/CAM/CAE software acts as the basis of this functionality, beginning with highly accurate and detailed 3D modeling. Some CAD software, like Autodesk Inventor, also includes onboard simulation for testing models’ response to aerodynamic conditions and stresses, such as finite element analysis (FEA), which predicts how sporting goods will react to forces like heat, pressure, and impacts.

Other software, like Autodesk Fusion, integrates CAM (computer-aided manufacturing), letting designers and engineers set up prototype manufacturing on CNC machines, 3D printers, and other machines. Software tools can also perform biomechanical analysis to provide insight into how sports equipment will interact with athletes’ bodies.

Literally all types of sporting goods can be designed with software, usually with CAD software that includes features for designing electronics and CAM features to assist in manufacturing equipment.

This software aids in sports equipment design for everything from wearable devices like fitness trackers and heart rate monitors to highly engineered athletic shoes. Software helps design the instruments that athletes wield, such as balls, rackets, and golf clubs; the gear that protects athletes, such as helmets, pads, and apparel; and the equipment athletes ride, like skis, skates, surfboards, and more.

Yes, sporting goods manufacturing software can integrate with existing manufacturing systems, because modern software is made to be interoperable with other systems through standardized data and communication protocols or software APIs (application programming interfaces).

Existing manufacturing systems can also be enhanced by adding Industrial Internet of Things (IoT) devices to the systems, which monitor them and send collected data to cloud-connected MES software or a manufacturing platform for valuable data analysis. In this way, existing sports equipment manufacturing systems can take advantage of advanced AI and machine learning, which power many IIoT devices and sensors, such as computer vision, as well as analytics that can lead to better efficiency, quality control, and predictive maintenance.