& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Consumer electronics span a wide range of consumer products from the latest smartphones and laptops to sleek headphones and innovative wearables—all packed with leading technology, seamless connectivity, and enhanced functionality. Recent breakthroughs in AI, chip miniaturization, touchscreen technologies, material sciences, and augmented reality (AR) continue to drive the evolution of these devices offering smarter and more personalized experiences.

Designing consumer electronics involves engineering, electronics, and simulation to create aesthetically appealing, high-functioning consumer electronics that meet sustainability, and regulation standards. The design process often starts with creative ideation and prototyping, followed by careful refinement to make sure the final product resonates with consumers and is profitable in the market. This cohesive approach also considers factors like user experience, ergonomics, and manufacturability to create products that are both innovative and practical for everyday use.

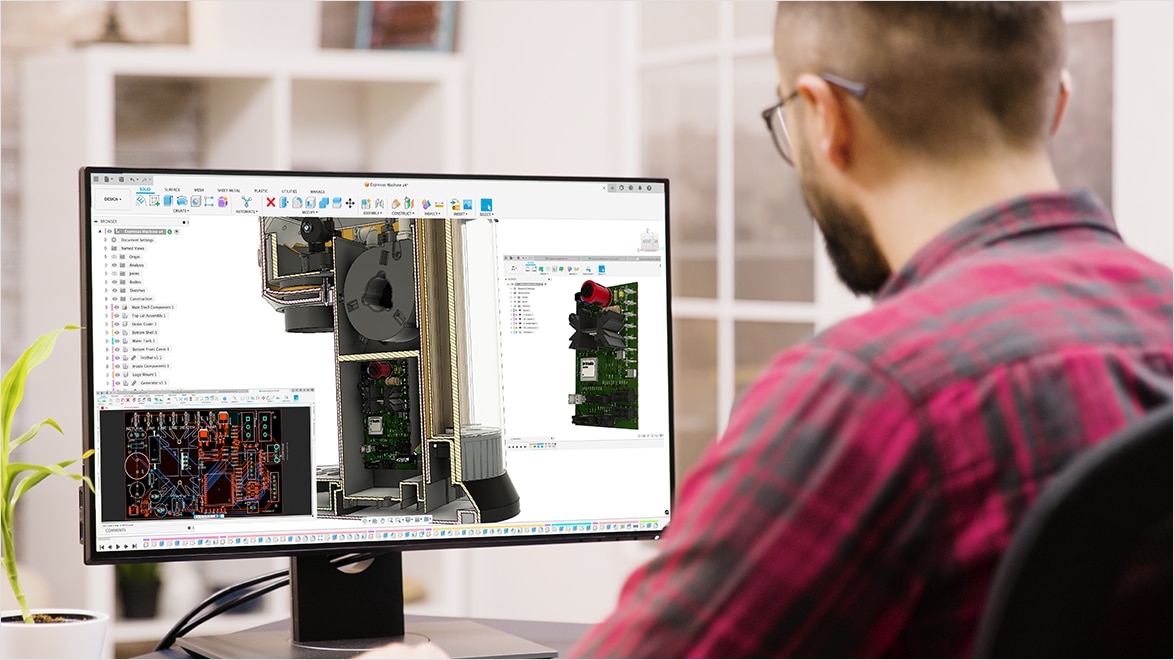

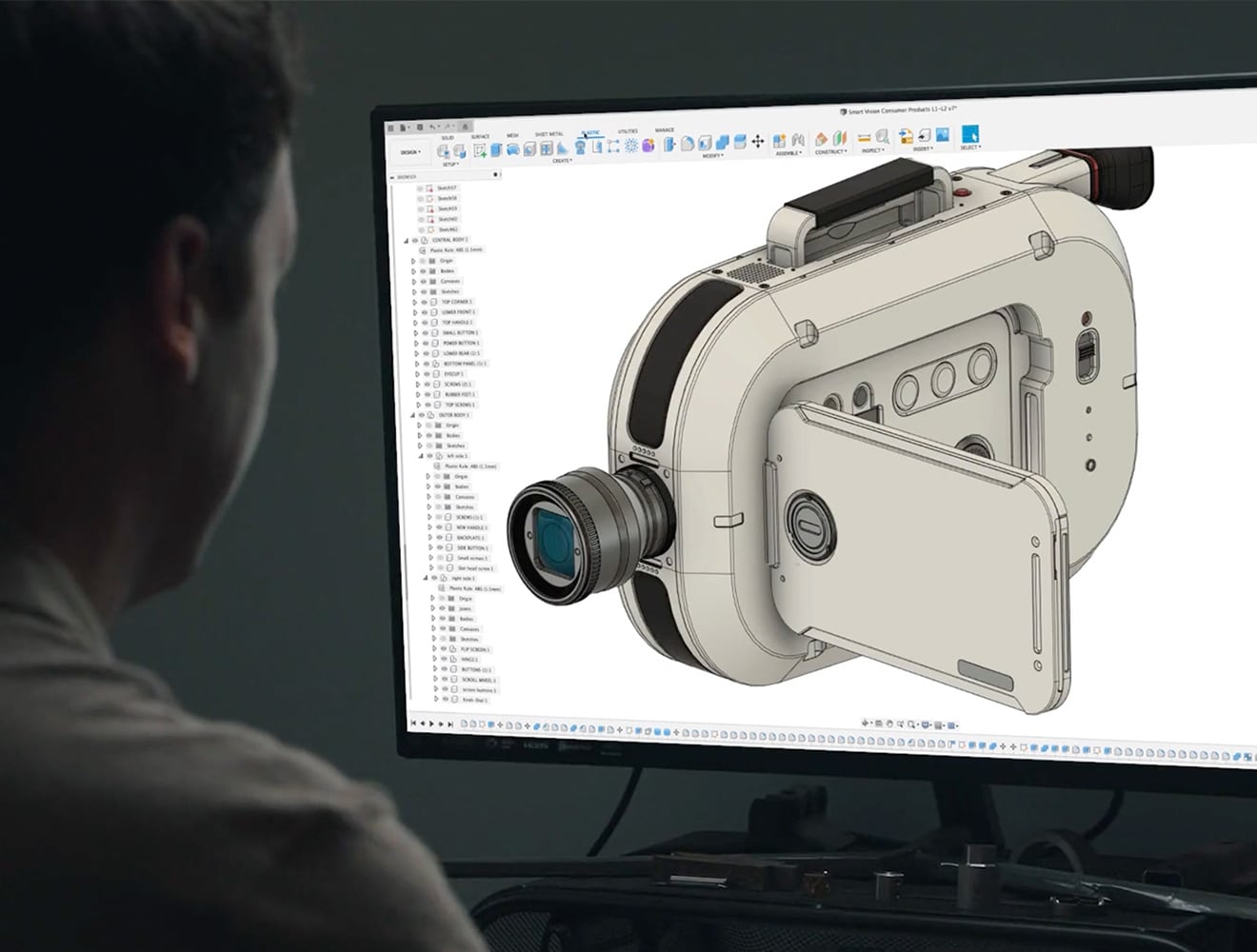

Consumer electronics design software, like Autodesk Fusion, plays a critical role in developing and iterating on design concepts before production. Fusion seamlessly integrates cloud 3D CAD, CAM, CAE, electronic design, simulation, and collaboration tools.

Its comprehensive consumer product design tools and connected workflows enable teams to move quickly from concept to design and into prototyping, moving seamlessly from mechanical enclosures to electronics. Sophisticated digital twin technology allows for real-world simulations speeding up the iterative process, making sure electronic devices function as they intend to and meet compliance standards. An intuitive interface along with user-friendliness, flexibility, and powerful capabilities make Fusion a top choice for designers.

As with any commercial process, consumer electronics development occurs in several distinct stages.

The initial ideas for the consumer electronics design should be rooted in having identified a market need that is currently not met or that can be met more effectively, and how feasible the idea is.

The initial design stage may see many different variations trialed before settling on one or more designs to take to the next stage. Autodesk’s generative design features can help with this.

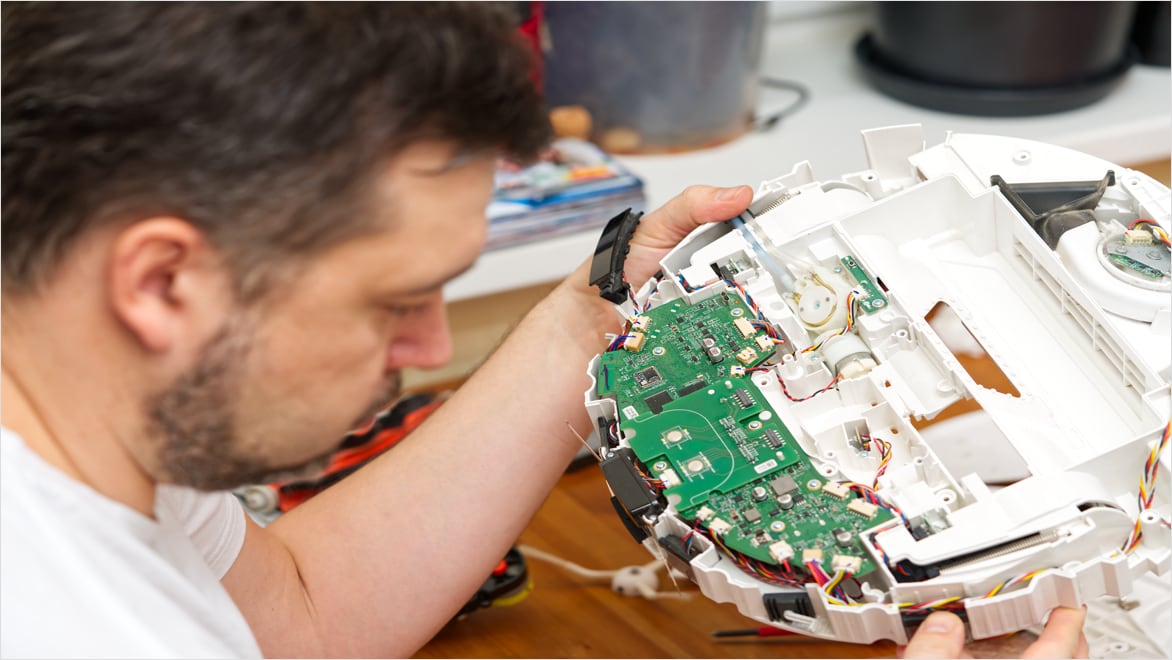

Building a working model of each design - a prototype – is essential for testing if it works the way it should, and for identifying areas of improvement.

Before finalizing the consumer electronics design, costs, manufacturing logistics and marketability should all be determined.

When the product is ready, it can be put into mass production.

An intuitive interface and parametric modeling capabilities allow rapid design iterations and easy modifications, accelerating the development cycle.

Advanced design projection capabilities in Fusion allow you to create precise designs where the enclosure and PCB harmonize perfectly.

Digital prototyping powered by digital twin technology, enables designers to simulate and optimize designs in real-time, significantly reducing overall prototyping costs.

Cloud-based collaboration tools in Fusion allow remote teams and stakeholders to work together, using their collective expertise.

When using Autodesk Fusion for consumer electronics design, the following considerations are essential:

Design Complexity: 3D, CAD, CAM, PCB, and simulation design capabilities in Fusion enable designers to quickly adopt design changes and explore multiple variations and creative concepts.

EMI Signal Integrity Analysis: Mitigating signal integrity issues in electronic designs is critical for product reliability. Fusion Signal Integrity Extension enables product designers and engineers to inspect and resolve issues with PCB signals in the design phase.

Prototyping: The consumer electronics industry is highly competitive requiring rapid iteration in order to minimize time to market. Fusion allows for a more agile testing and development process, cutting down on prototyping costs, time, and resources.

Manufacturing: Getting all the correct files ready for manufacturing is critical to a smooth fabricating process. Autodesk Fusion simplifies this by easily generating and exporting fabrication files including Bill of Materials (BOM), ODB++, Gerber, along with mechanical files such as STEP, and DXF.

Learn how designers use Autodesk software to design simple to complex devices with precision.

Get up to speed with everything you need to know about the Fusion electronics workspace.

Start creating a schematic, the groundwork to design an electronic design.

This ultimate guide will show you how to leverage the Fusion Electronics Signal Integrity Extension powered by Ansys.

Learn how to set up PCB layers for your designs and get files ready for manufacturing.

Incorporating 3D modeling software into your product design workflow has major benefits, learn what they are.

Get sustainability insights from leaders in the consumer electronics industry from a recent study.

Careful consideration of the following elements during consumer electronics design can make all the difference.

Modern consumers don’t want to spend a long time reading manuals, so aim to create consumer electronics that are naturally easy to use and understand.

While quality is of the utmost importance, unless it’s a premium product it’s wise to keep costs firmly in mind when designing consumer electronics.

Making multiple prototypes to test out different design features and variations can result in a far better final consumer electronics design with all issues ironed out.

When choosing materials during consumer electronics development, durability, availability, cost and functionality should all be kept firmly in mind.

Limbitless Solutions is transforming advanced prosthetic solutions for children with limb differences, solutions that are often difficult to find and expensive to purchase. The team adopted Fusion because “it is an all-in-one software." The electronics workspace makes it possible to have both schematic and board files open at the same time, allowing seamless change updates.

You can’t miss a Rivian truck or SUV driving on the road these days. It's an all-electric, all-terrain-ready vehicle with a glossy exterior. Simply put, there isn’t anything like them. Take an inside look at how the rapid prototyping group within Rivian’s special projects team uses Fusion to make fast and reliable prototypes — from 3D modeling to advanced manufacturing with the Manufacturing Extension.

UK-based Photocentric is revolutionizing mass manufacturing with their innovative 3D printers, including the LC Titan, the world's largest LCD 3D printer, and the LC Nano, the fastest. Fusion plays a crucial role in their design process, utilizing tools like generative design and drawing automation to enhance collaboration and accelerate workflows.

The marvelous award-winning, best-selling toy didn’t happen by chance. The magic behind Magic Mixies lies in a sophisticated design and manufacturing process driven by Fusion, seamlessly integrating electronics and mechanical design. Fusion their team the ability to jump in and use the form tools to sculpt, and the electronics and mechanical teams to build and design on that same file.

Consumer electronics software can help greatly with design and manufacture, but there are still many hurdles to overcome.

Today, technology can move so fast that a design may become obsolete before it completes the product cycle, so it’s important to stay abreast of current and future consumer electronics developments.

Falling costs of consumer electronics manufacturing and other factors have resulted in a saturated marketplace. With so much competition, it’s important to know who your direct competitors are and how their products compare to yours.

Most consumer electronics contain a variety of materials and components, including rare earth metals. Changes in global markets and availability at the source can see manufacturing costs vary widely.

– John Sparkman , Co-founder, Limbitless Solutions

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

With more awareness than ever before of environmental issues, companies in all industries must work to make their products as sustainable as possible. Consumer electronics manufacturing can be particularly resource intensive, drawing on many materials and components, including those made from rare earth metals. For this reason, it’s essential to consider sustainability when designing consumer electronics, such as how easily products and components can be recycled, and the amount of resources used in their production. Fusion’s analysis, material selection and generative design features can aid this process.

Consumer electronics software facilitates the development of consumer products like smartphones, wearable devices, smart home technology, and gaming consoles by streamlining electronics design and manufacturing processes.

A wide range of consumer electronic devices such as smartphones, tablets, gaming consoles, and smart home devices are designed and created with electronics and mechanical design software.

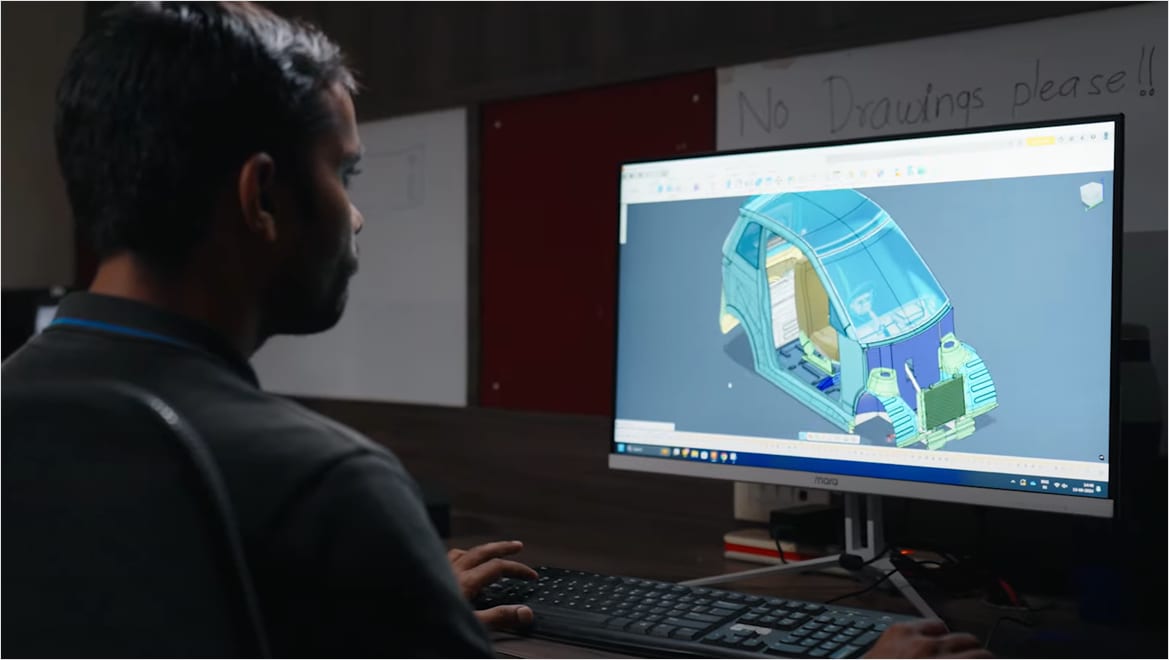

Consumer electronics design software is used to create engine control units (ECUs), navigation systems, instrument clusters, sensors, advanced driver-assistance systems (ADAS), and other automotive electronic components, charging.

From vital sign monitors to portable ECG machines, to everyday home blood pressure devices, consumer electronics software enables the creation of innovative and precise electronic components for medical applications.

Augmented reality to fitness watch devices feature precise integration of sensors, chips, connectivity, and user interfaces. Effective design and manufacturing processes are essential to make sure these devices are functional, comfortable, and durable for everyday use.

Consumer electronics design software is often used in designing toys and learning devices that have increasingly integrated consumer electronics, offering interactive features like touchscreens, voice recognition, and connectivity to enhance educational experiences.

Robotic design companies like Limbitless benefit from seamlessly integrated engineering workflows in Autodesk Fusion. Designers can access tools to create PCB designs for robot controllers, sensor interfaces, motor control boards, mechanical enclosures, and more.

To design consumer electronics, you'll typically need software like Autodesk Fusion for mechanical and electronic PCB design and simulation along with software for firmware development. Additionally, tools like Adobe XD or Figma for UI/UX design and MATLAB for system simulation are recommended for creating and testing prototypes efficiently.

The latest trends in consumer product design, specifically for electronics, includes AI-powered gadgets, smart home devices, wearable technology, 5G smartphones, energy-efficient appliances. Innovations like foldable screens, and wireless charging are also gaining electronics featuring flexible circuits continue to gain popularity.

Modern technologies like 3D printing With 3D printing, manufacturers can easily produce unique and intricate designs without the need for molds. Designers can create quick enclosures and see potential products come to life and easily incorporate design changes. Consumer electronics can be tested and refined faster, resulting in a more efficient design process. 3D printing also offers the potential for greater sustainability. As a form of additive manufacturing, it minimizes waste by using only the material needed. Moreover, it has the capacity to use bioplastics and recycled materials, positioning 3D printing at the forefront of eco-conscious manufacturing processes

Autodesk provides a suite of software that is extensively utilized by consumer product designers.

Autodesk Fusion can be used alone or alongside the Signal Integrity Extension. A subscription to the extension will unlock additional capabilities in the Fusion electronics workspace with advanced workflows for consumer electronics design and manufacturing.

Yes, Autodesk Fusion is available for free personal use for individuals who are doing home-based, non-commercial design projects. This version includes basic functionality. However, it is important to note that to qualify for free usage, users should generate less than $1,000 USD in annual revenue from their designs. You can register for a personal license on the Autodesk website. Or you could consider getting Fusion with full functionality. See plans and pricing here.

Consumer electronics frequently encounter problems such as diminished battery life, connectivity disruptions, software errors, and hardware failures. Ensuring device longevity can requires regular software updates and/or adhering to the manufacturer's usage recommendations.

Autodesk Fusion's rendering tools helps designers create visually compelling, photorealistic product renders to share with stakeholders and investors to help visually sell and market their consumer products.

Autodesk Fusion helps consumer electroncis designers and manufacturers stay competitive in a number of ways:

Advanced capabilities: Fusion integrates electronic PCB, CAD, 3D modeling, simulation, and collaboration tools enabling the production of complex PCBs and their mechanical enclosures with advanced simulation to enhance product quality, streamline workflows, and speed up time to market.

AI enhancements: Fusion incorporates artificial intelligence to enhance manufacturing. The AMAIZE add-in, for instance, uses AI to predict and resolve print issues, optimize print files, and gain valuable design insights, significantly improving the manufacturing process.

Unified workflows: From concept to manufacturing, Fusion streamlines workflows with integrated cloud-based CAD, CAM, CAE, and PCB design tools. It unifies design and manufacturing capabilities, data, and technology.

Innovation and sustainability: Fusion is continuously evolving, incorporating AI, machine learning, and generative design technologies to push the boundaries of product development.

Anytime, anywhere access: Fusion allows real-time team collaboration and provides access to designs anywhere, anytime, accelerating time-to-market.

Fusion by Autodesk supports sustainable consumer electronics design in several ways:

Materials: Fusion includes resources to help designers choose sustainable materials such as bioplastics or recycled materials.

Additive manufacturing: Fusion supports 3D printing, which can significantly reduce waste and energy usage.

Generative design: Fusion's generative design capabilities help reduce material usage, contributing to sustainability.

Remember, proper assessment is needed when choosing materials to ensure the most sustainable options are selected.