& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

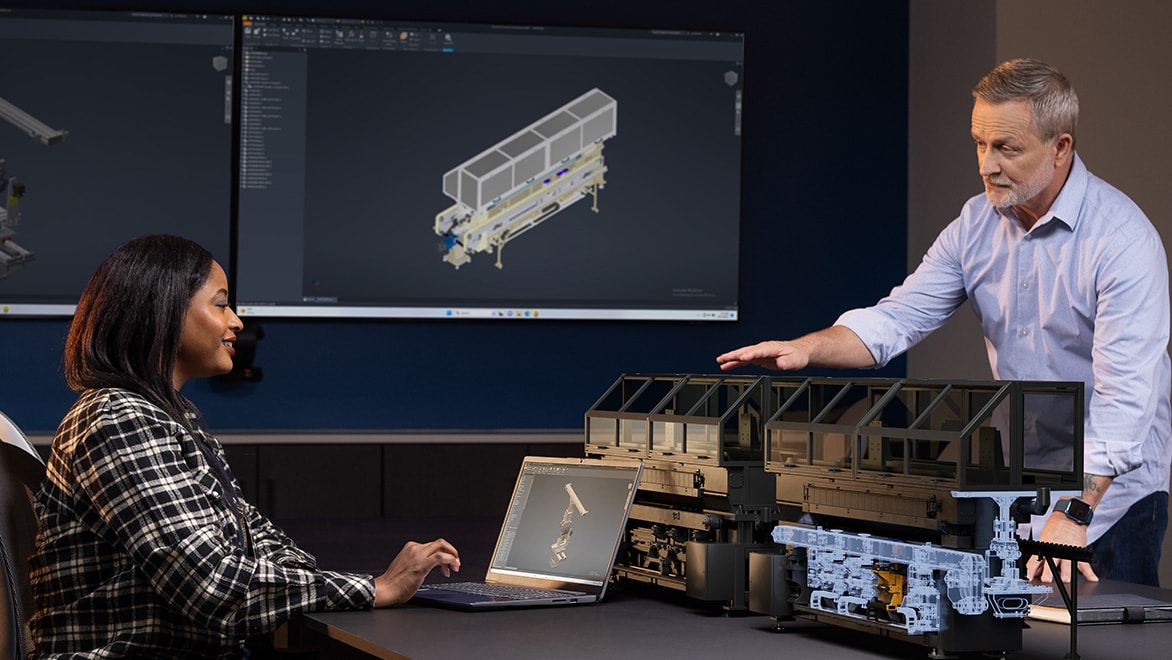

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

CPQ stands for Configure, Price, Quote. CPQ software is a solution that helps businesses configure complex products, price them, and generate quick, consistent, accurate quotes for customers. In industries like manufacturing, where products often have hundreds of customizable options, CPQ solutions help you select and offer the right product at the right price.

Let’s say you manufacture industrial machinery. A customer might need a specific model with added features like additional sensors, custom sizing, or different materials. Doing this manually, you’d have to dig into your price lists, check inventories, and make sure every customization is feasible before you can accept and price the request.

With CPQ solutions, all of this happens automatically. The software takes care of the complex configurations based on customers’ requirements, ensuring nothing is missed while generating a fast and accurate quote. CPQ software connects to your customer relationship management (CRM) and enterprise resource planning (ERP) systems, integrating the process of quoting on work seamlessly into your workflow.

Speed, accuracy, and customization are everything in manufacturing. Staying competitive means adopting tools that help you work faster and smarter. One such tool is Configure Price Quote (CPQ) software.

If you’re new to CPQ or unsure how it fits into your manufacturing process, think of it as a "super calculator" for generating price quotes for complex orders.

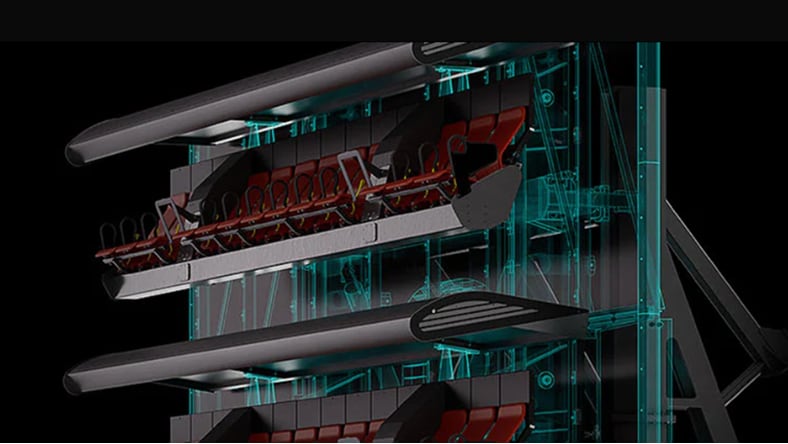

Solve complex problems efficiently with the ultimate set of engineering applications.

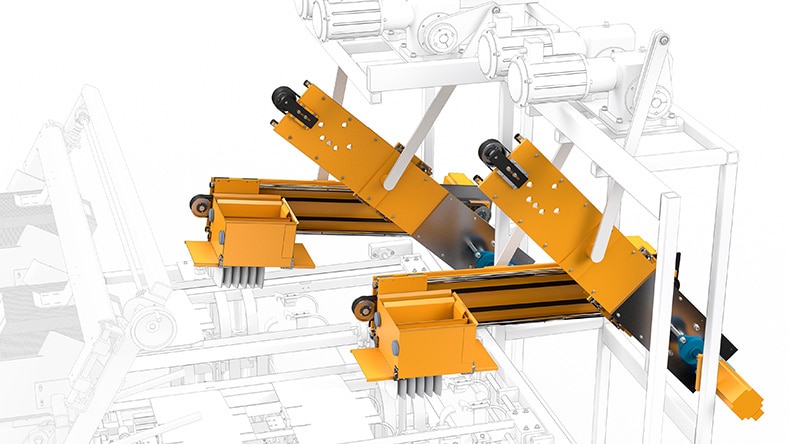

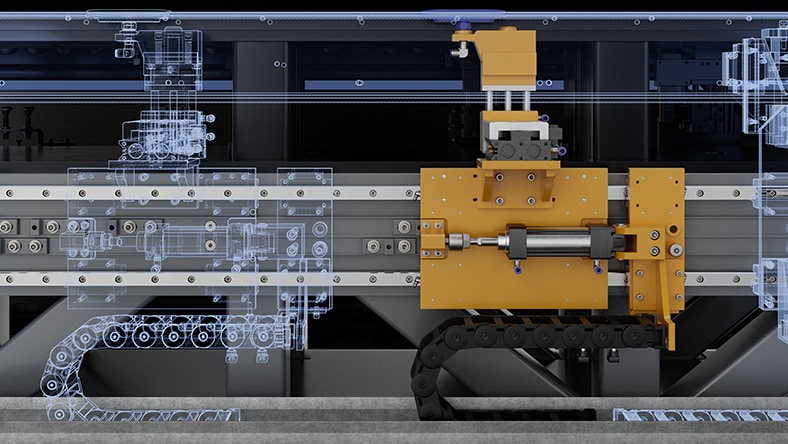

Image courtesy of Mastenbroek

Gain access to powerful 3D CAD tools for mechanical design, simulation, and documentation with integrated modeling, manufacturing, and model-based definition capabilities.

Image courtesy of Dynamic Solutions

Transform your team’s product development process with integrated design, manufacturing, electronics, and data management in a single cloud-based solution.

Autodesk Platform Services, formerly known as Autodesk Forge, integrates CPQ (Configure, Price, Quote) capabilities with comprehensive manufacturing solutions through a rich set of APIs and cloud services. This integration connects design and engineering data with CPQ systems, enabling manufacturers to create interactive 3D product configurations, generate accurate pricing, and produce dynamic proposals directly from their CAD models.

By automating the quoting process, Autodesk Platform Services streamline workflows, reduce errors, accelerate sales cycles, and enhance customer satisfaction by delivering precise, customized solutions quickly.

CIDEON

CIDEON, German systems integrator and process consultant, used CPQ tools to connect different departments and improve collaboration.

Codeo

Turkish engineering firm, CODEO, used CPQ to move from design to product quickly, allowing them to keep up with fast-paced industry demands.

Lixil

LIXIL, a Japanese company known for household fixtures, used CPQ to cut drafting time by 30%, making their design process more efficient.

Manufacturing is all about personalization. Customers want products tailored to their specific needs, whether in size, color, functionality, or material. But personalization can lead to errors if managed manually. CPQ software eliminates these issues by automating the customization process, reducing the chance of errors and speeding up the quoting process.

Instead of spending hours configuring products, pricing them, and drafting quotes, CPQ does all the heavy lifting in minutes. This allows your sales and engineering teams to focus on other tasks.

CPQ ensures all pricing is accurate. You won’t have to worry about underpricing, overpricing, or missing details from the configuration. It reduces human error, making your quotes more reliable.

The faster you provide a quote, the faster you can close a deal. CPQ cuts down quote generation time from days to hours, helping you stay ahead of your competitors.

As your business grows, manually creating quotes becomes unmanageable. CPQ scales with you, handling increased complexity and volume without sacrificing speed or accuracy.

Let’s break down how CPQ fits into your manufacturing workflow, from configuration to the final quote.

CPQ software allows your sales team to input the customer’s desired product specifications. Whether customizing a product’s size, adding extra features, or changing the material, CPQ makes it simple to configure even the most complex products. This feature is particularly useful for manufacturers offering a wide range of product variations, such as machine tools, electronics, or furniture.

CPQ uses predefined rules and real-time data to calculate the price. It factors in everything from raw material costs and production expenses to market demand and profit margins. By automating this process, you ensure pricing is consistent and accurate, no matter the complexity of the configuration.

After the product is configured and priced, CPQ generates a professional quote you can send directly to the customer. This quote often includes detailed product specifications, pricing breakdowns, and delivery timelines. It also ensures everyone on your sales team is working with the same information, maintaining consistency across the board.

CPQ software doesn’t just help the manufacturing process—it transforms how you sell your products. By integrating CPQ into your existing CRM system, you can create a flow from initial customer inquiry to final product delivery.

Here’s how CPQ impacts manufacturing sales:

Beyond improving workflows, CPQ has a tangible impact on your bottom line:

To maximize the value of CPQ, it should integrate with other tools your company already uses. For manufacturers, this often means linking CPQ with your ERP or CRM systems. This integration helps ensure that the entire process—from configuration to manufacturing to final delivery—is streamlined.

For example, by linking CPQ with your ERP, you can check real-time inventory data to ensure that the customized product you’re quoting can be made and delivered on time. By integrating with your CRM, your sales team can pull up past customer interactions, helping them make better-informed decisions during the quoting process.

When choosing the right CPQ for your manufacturing business, consider the following:

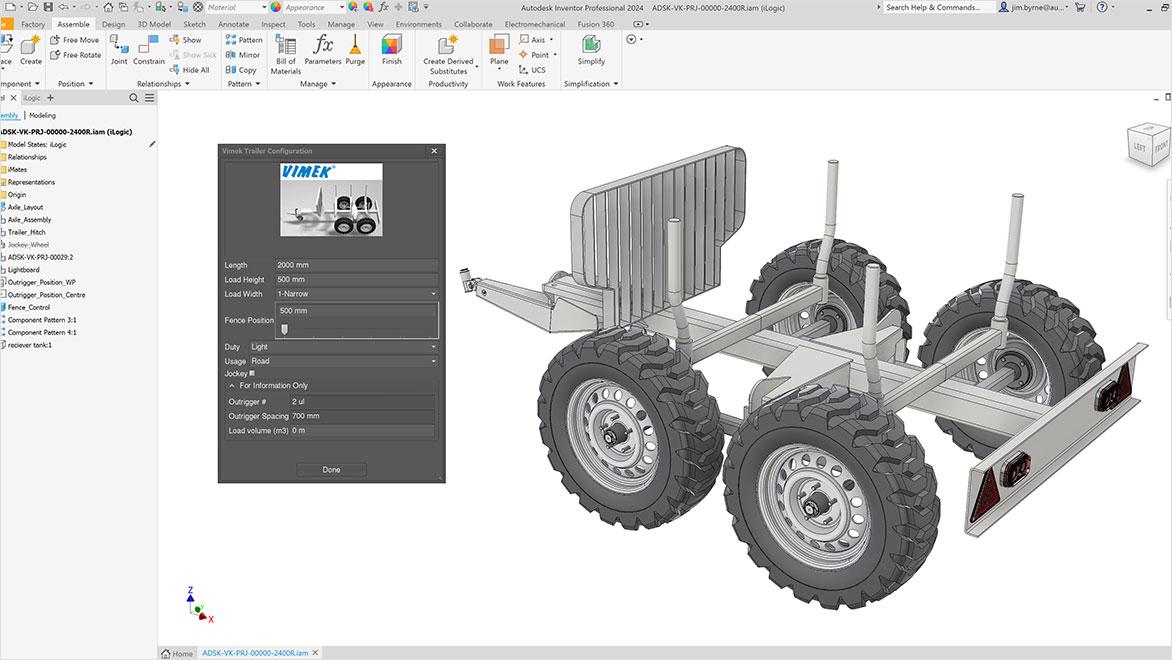

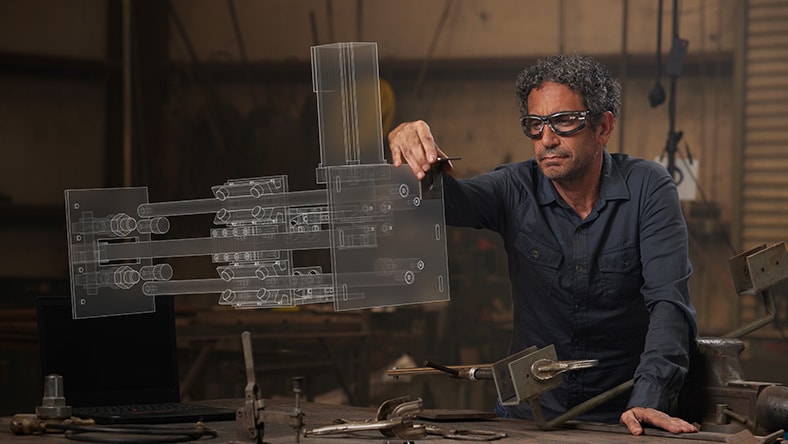

iLogic in Autodesk Inventor is a powerful tool for automating product configurations. It enables customizable rules for assembling products efficiently, making it an ideal foundation for CPQ.

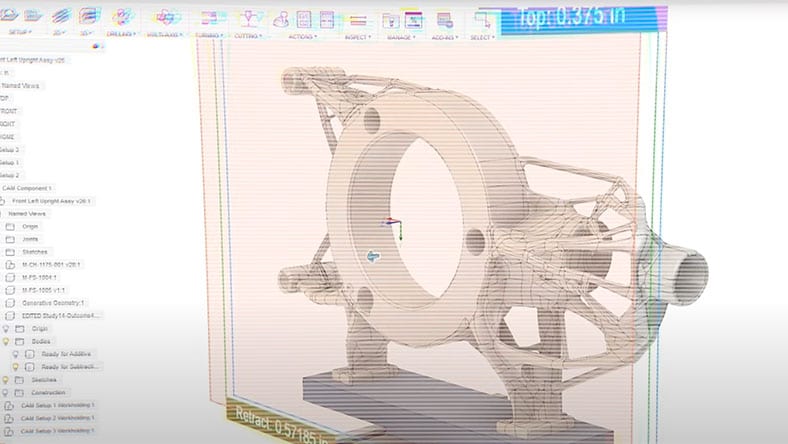

Learn how to pull data from Inventor and use it in a CPQ system through Autodesk’s Forge Design Automation. This process allows for seamless data integration and efficient product configuration.

CPQ stands for configure, price, quote—the three components of CPQ software.

Configure, price, quote systems automate a process that lets a customer choose specific product variables and get accurate costs.

Trying different colors, materials, dimensions, or other changes is done in a few clicks, using the product taken directly from the 3D design file and deployed in a simple browser window.

Throughout the process, product pricing is automatically updated, and the cost of their final choice of variables is transposable into a formal quote from within a CPQ manufacturing business system.

Customer relationship management (CRM) software is a business-development tool that tracks customer contacts, organizes records of interactions, and maintains professional connections and prospects.

CPQ manufacturing software integrates directly with the data from your design, letting customers choose from available product variables.

Throughout that process, the system displays updated pricing and lets you provide an accurate quote based on their choices.

Although the two are different, good CPQ software will provide the means to share data with your CRM system for a more comprehensive overview of your interactions with a customer.

CPQ (Configure Price Quote) software helps manufacturers quickly configure complex products, calculate accurate prices, and generate professional quotes. It streamlines the process by automating product customization, pricing, and quote generation.

A Configure, Price, Quote (CPQ) system helps customers pick different options for a product—like colors, materials, or sizes—and instantly see the updated cost. This happens in a few clicks through a web browser, using the 3D design of the product. As customers make changes, the price automatically updates. When they’re done, the final choices can quickly be turned into a formal quote.

CPQ uses predefined rules and real-time data to calculate prices, eliminating human error. It ensures that all factors, like material costs and customization, are considered in the final quote.

Yes, CPQ software can integrate with other systems like ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management) software to provide real-time data and streamline workflows.

CPQ accelerates the sales process by automating product configurations, ensuring consistent pricing, and generating quotes quickly. This leads to shorter sales cycles and faster deal closures.

CPQ provides customers with fast, accurate, and detailed quotes, reducing wait times and increasing their satisfaction. It also ensures customers receive exactly what they want in their configurations.

Manufacturers that deal with complex products, high levels of customization, or large product catalogs—such as those in machinery, electronics, or industrial equipment—benefit the most from CPQ.