& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Cloud based manufacturing is a modern approach to production and manufacturing that leverages cloud computing technologies. It includes the use of cloud-based platforms to manage, control, and optimize manufacturing processes and resources.

Cloud based manufacturing software, like Autodesk Fusion is hosted on cloud servers to facilitate various aspects of the manufacturing process. These solutions are designed to optimize operations, improve collaboration, and provide real-time insights into production activities.

Cloud manufacturing software can be rapidly deployed, helping manufacturers quickly adapt to changing market demands and customer needs.

Cloud manufacturing solutions can easily scale up or down based on the needs of the business, allowing for flexibility in resource management.

Cloud based manufacturing software enables real-time collaboration among teams regardless of their location, with access to data at anytime, anywhere on any device.

Gain access to real-time visibility into manufacturing operations, allowing for quicker decision-making. Access to advanced analytics and reporting capabilities help in identifying trends, improving processes, and increasing productivity.

Cloud based manufacturing solutions often reduce the need for significant upfront capital investment in hardware and software, as they typically operate on a subscription model. This helps in converting capital expenditure to operational expenditure.

Cloud-based manufacturing software integrates with other cloud-based tools and third-party applications, enhancing workflow efficiency and more streamlined operations.

Choosing a cloud based manufacturing software solution is a significant decision that can impact the efficiency and productivity of your operations. Here are some primary factors to consider:

Integration: Make sure the solution integrates well with your existing systems and includes robust API support.

Security: Check to make sure the software adheres to industry standards and regulation for data security and privacy. Look for features such as data encryption and user access controls.

Cost and ROI: Evaluate the total cost of ownership and potential ROI by considering subscription fees, implementation costs, training, ongoing maintenance, and the software's ability to improve efficiency, reduce costs, and enhance productivity.

Implementing Fusion, Autodesk's industry cloud for manufacturing involves strategically integrating its core components to enhance cloud based manufacturing workflows: Fusion for seamless cloud CAD/CAM/CAE/PCB operations, datat management, and collaboration, Fusion Manage for robust lifecycle management, and Fusion Operations for real-time insights into shop floor activities.

Complemented by Autodesk Platform Services (APS), extensive APIs, professional-grade extensions, and strategic partnerships, these tools create a comprehensive cloud manufacturing solution that supports every phase of your design and make process.

cloud based CAD, CAM, CAE, & PCB

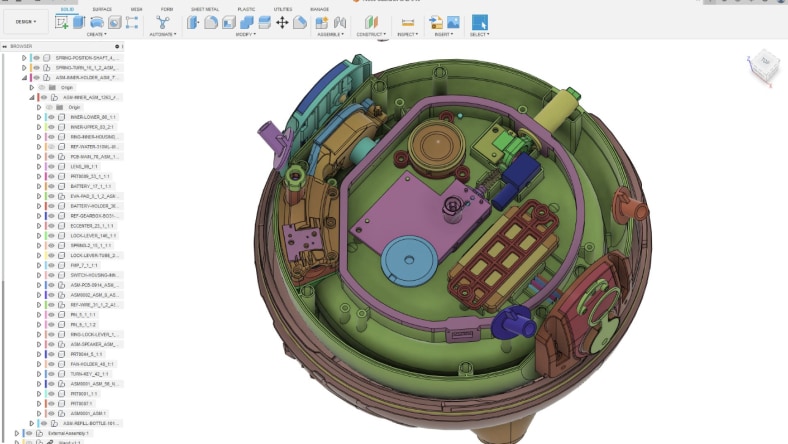

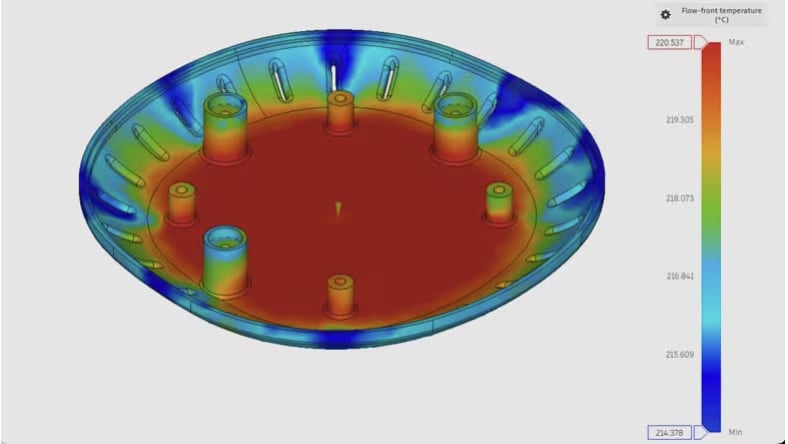

Fusion integrates CAD, CAM, CAE, and PCB capabilities into a single platform, allowing users to design, simulate, and manufacture products using cloud-based tools and resources. This enables collaboration, real-time data access, and streamlined workflows across different stages of product development and manufacturing.

Cloud based PLM

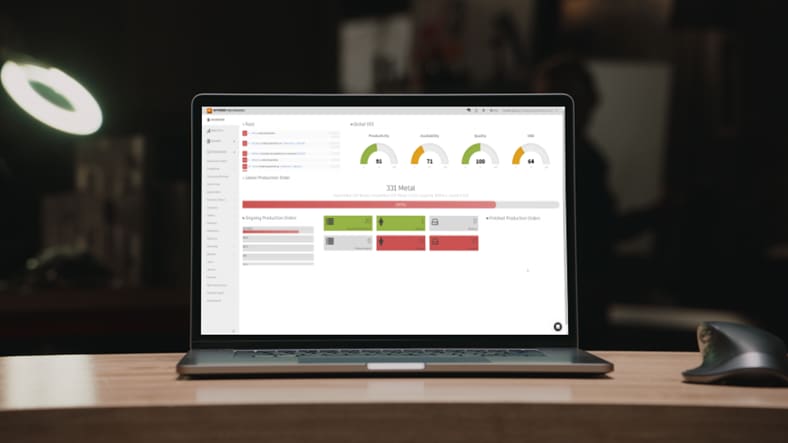

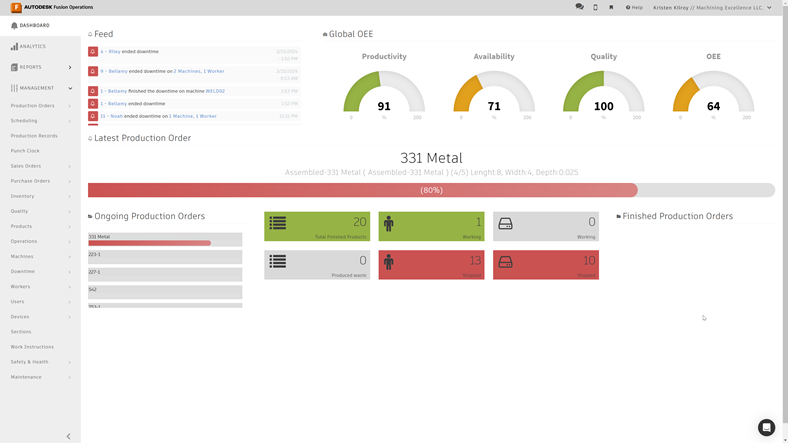

Autodesk Fusion Operations helps manufacturers manage and optimize their production operations, offering features like inventory management, production scheduling, and real-time data analytics. Being cloud-based, it provides the flexibility to access and manage manufacturing processes from anywhere, enhancing collaboration and operational efficiency.

Manufacturing and fabrication insights

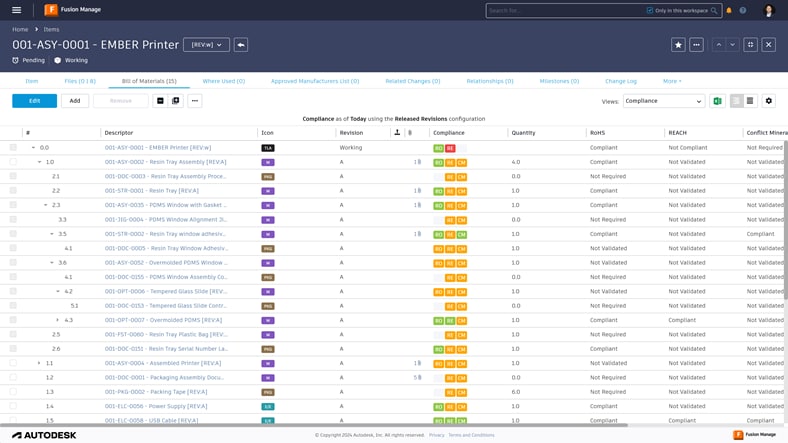

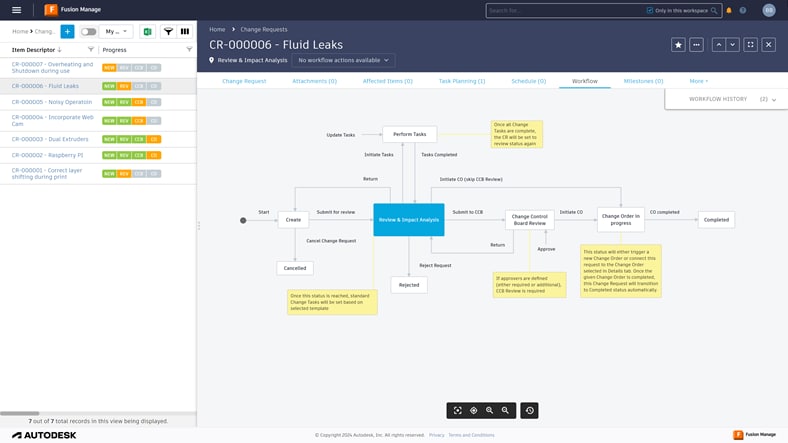

Fusion Manage is a cloud-based product lifecycle management (PLM) software that helps manufacturers manage product data, automate workflows, and improve collaboration across the product development lifecycle. Its also includes open API integration with other systems like PDM, ERP, and CRM.

– Ryan McCullough, Director of Prototype Development, Shiftwave

Fusion can simulate real-world conditions, including stress and motion, ensuring a products durability and functionality before production.

BOM in Fusion Manage provides a comprehensive list of components, materials, and parts required to manage a product, facilitating efficient product lifecycle management and collaboration.

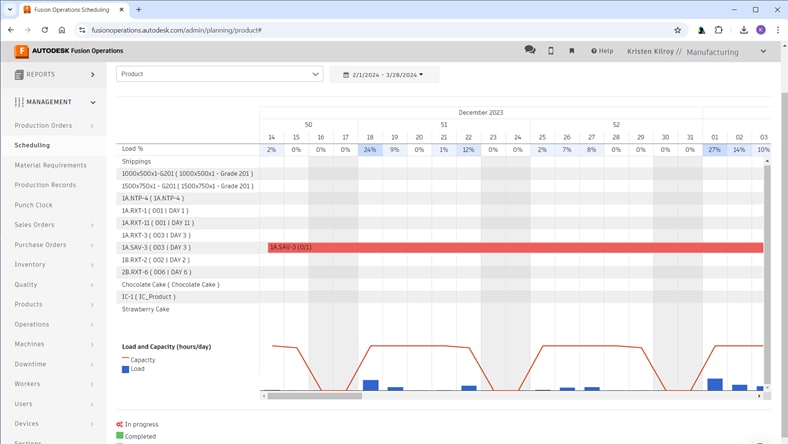

Production scheduling in Fusion Operations involves planning and organizaing manufacturing processes to optimize resource utilization, reduce lead times, and ensure on-time delivery of products.

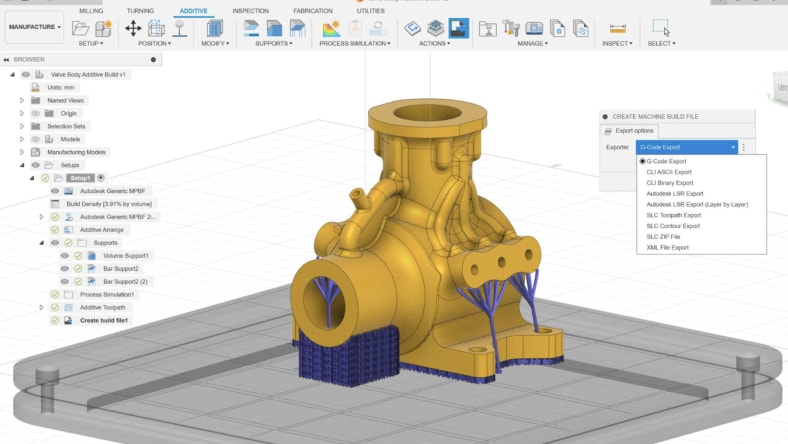

Fusion can automatically create optimized machining paths for CNC operations, enhancing efficiency and precision in the cloud based manufacturing process.

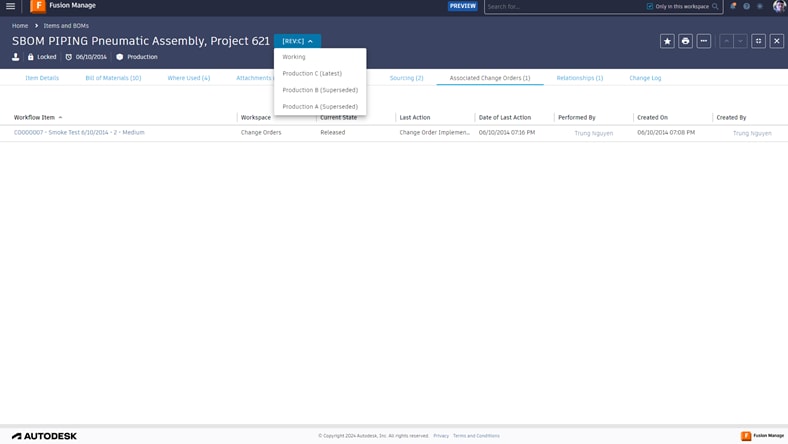

ECO in Fusion Manage is a formalized process for managing and documenting changes to product designs, ensuring all modifications are systematically reviewed, approved, and implemented.

Fusion Operations provides real-time visibility and control over manufacturing activities, enhancing operational efficiency and productivity on the production floor.

Fusion supports 3D printing and other additive manufacturing processes, enabling rapid prototyping and production.

Fusion Manage ensures that all changes to product items are meticulously tracked, documented, and managed, maintaining consistency and traceability throughout the product lifecycle.

Explore how cloud based manufacturing platforms have reshaped the workplace and how Autodesk Fusion offers a solution for manufacturers.

Learn why undergoing digital transformation in manufacturing is more vital than ever and how Autodesk Fusion can support.

Explore digital transformation in the context of cloud based manufacturing, including ongoing trends and ways to overcome perceived barriers.

Cloud manufacturing is a service-oriented networked manufacturing model that utilizes cloud computing technologies to integrate and share manufacturing resources and capabilities. It enables manufacturers to access, manage, and optimize production processes and resources over the internet, enhancing collaboration, efficiency, and scalability.

Cloud based manufacturing software is a digital platform hosted on remote servers that provides tools for managing and optimizing manufacturing processes via the internet. It allows manufacturers to streamline operations, monitor production in real-time, and collaborate across different locations without the need for extensive on-premises infrastructure.

Cloud manufacturing ERP (Enterprise Resource Planning) is a cloud-hosted system that integrates various business processes and manufacturing operations into a unified platform accessible over the internet. It provides real-time data and analytics to streamline workflows, improve resource management, and enhance decision-making across the entire manufacturing enterprise.

The top five benefits of cloud manufacturing are:

Yes, Autodesk Fusion is a cloud based manufacturing software. It integrates CAD, CAM, and CAE capabilities into a single platform, allowing users to design, simulate, and manufacture products using cloud-based tools and resources. This enables collaboration, real-time data access, and streamlined workflows across different stages of product development and manufacturing.