& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

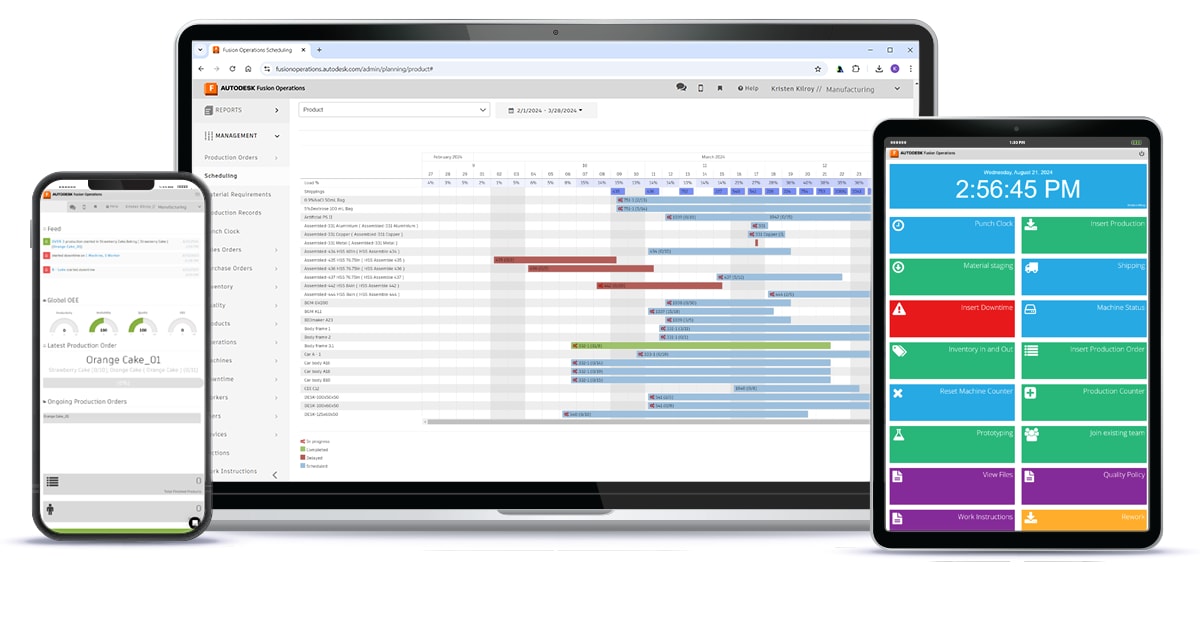

Fusion Operations is production management and production floor tracking software that allows you to optimize your operations and make better, data-driven decisions.

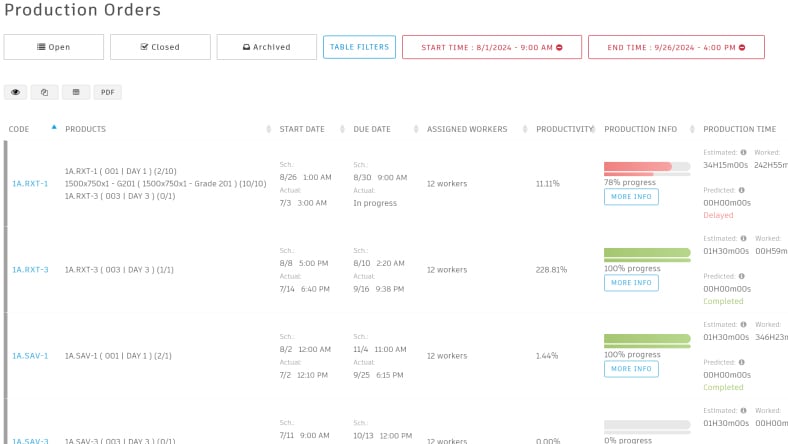

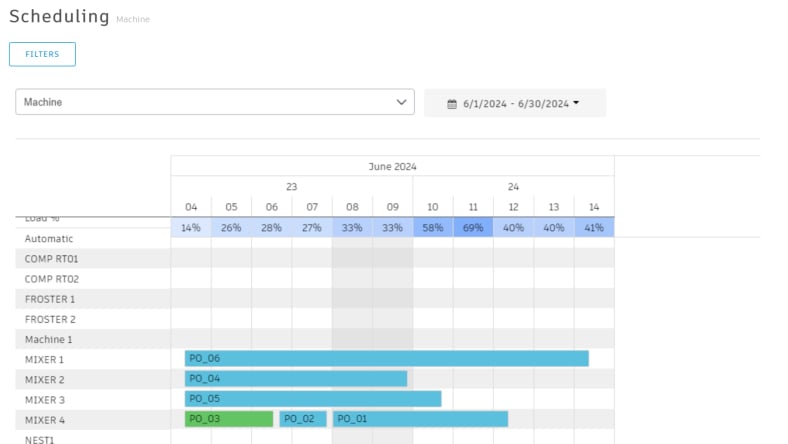

Autodesk Fusion Operations's advanced interface allows for precise scheduling, ensuring that your manufacturing processes are always on track. By accurately predicting production times, you can optimize resource allocation and reduce downtime.

Agility is key! Autodesk Fusion Operations offers the tools you need to quickly adapt to market demands, ensuring that you can customize products efficiently without compromising on quality.

Simplify your production planning with Autodesk Fusion Operations's intuitive drag and drop scheduling feature. Adjust and optimize your schedules with ease, ensuring maximum efficiency.

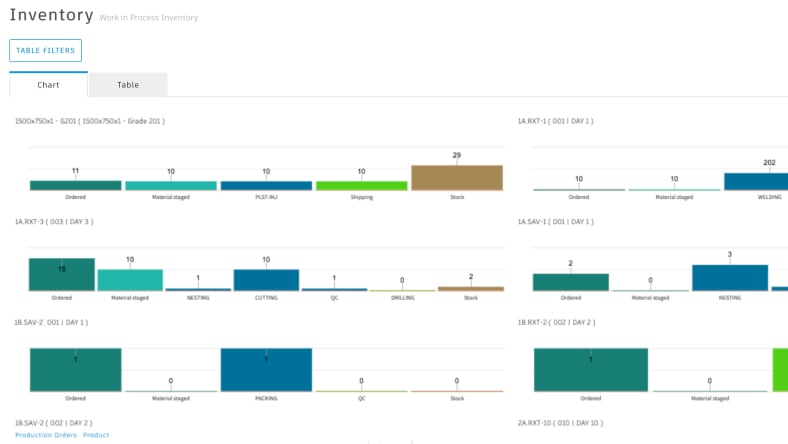

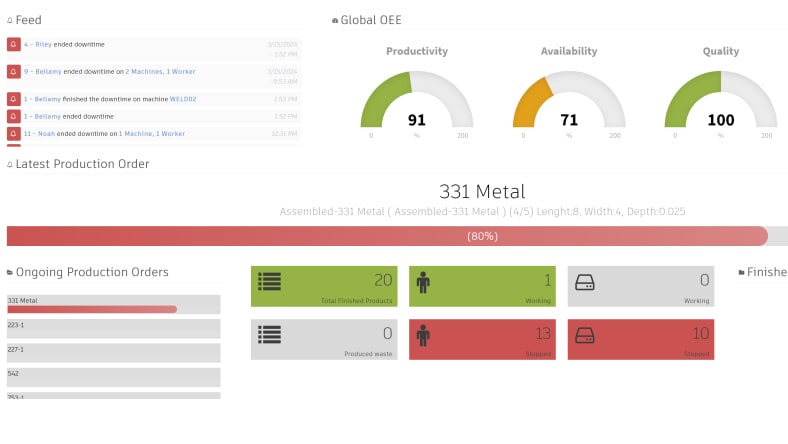

Get instant insights with real-time data on your production line. From machine performance to team productivity, Autodesk Fusion Operations keeps you informed, helping you preemptively address potential bottlenecks.

Productivity increase year over year, reported by ReChaco, a division of Chacos.

Less rework year over year, reported by ReChaco, a division of Chacos.

Create sales orders to base production orders off of to help ensure real-time synchronization between sales and production activities.

Minimize the risk of running out of materials with real-time inventory counts that update based on production records.

Manage production floor schedules for workers, machines, production jobs, and planned maintenance for improved flexibility when planning jobs.

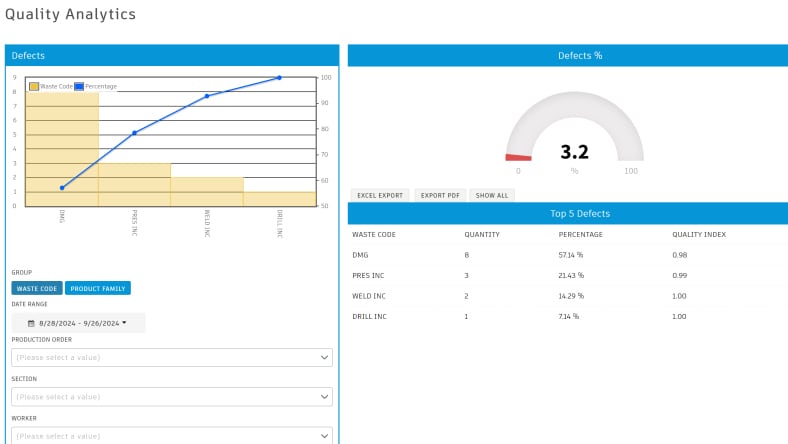

Log waste categories and track production trends to help identify steps in your process that may need improvements.

Streamline data logging and access production information anytime from anywhere through a simplified mobile app.

Visualize factory performance through real-time reporting tools such as Overall Equipment Effectiveness, or OEE, charts.

Start effectively planning, managing, tracking and analyzing your manufacturing shop floor production with Autodesk Fusion Operations.

Simply fill in the form, and get a free 14 day trial!

Would you like to speak to someone immediately?

Call +1-844-556-4414 to speak with a Fusion Operations expert.

A Manufacturing Execution System (MES) is a software solution to automate and digitize manufacturing processes. Manage, monitor, and track the transformation of raw materials into finished products in real-time. Gain insight into manufacturing operations to see how to improve performance, lower costs and increase production efficiency.

Autodesk Fusion Operations brings together MES and ERP capabilities, consolidating the number of tools used, streamlining your workflow to require fewer tools, and enabling communication of relevant information back and forth.

Autodesk Fusion Operations is a multi-capable tool, used by manufacturing engineers, production managers, quality managers, fulfilment, and shop floor fabricators.