& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Software like Autodesk's AutoCAD can help the reverse engineering process

Reverse engineering is the fascinating process of taking something apart to discover how it works. The approach involves carefully disassembling finished products and analyzing each component to see how they work together. You then document these discoveries and insights, using this knowledge to recreate, improve, or innovate products.

Modern reverse engineering software has taken the field a step further. Automated analysis tools speed up the discovery process, while advanced scanning and modelling ensure accuracy. Digital tools can adapt the method to various products and industries, and data-driven software provides the insights you need through detailed analysis. Teams can share their findings and work together to create better products.

Many industries use reverse engineering to better understand their products and technologies.

Engineers can use reverse engineering to scan and analyze everything from vintage aircraft parts to complex engine components to create digital replicas. This enables them to modernize classic designs, produce spare parts for out-of-production vehicles, and optimize components for better aerodynamics, fuel efficiency, and performance.

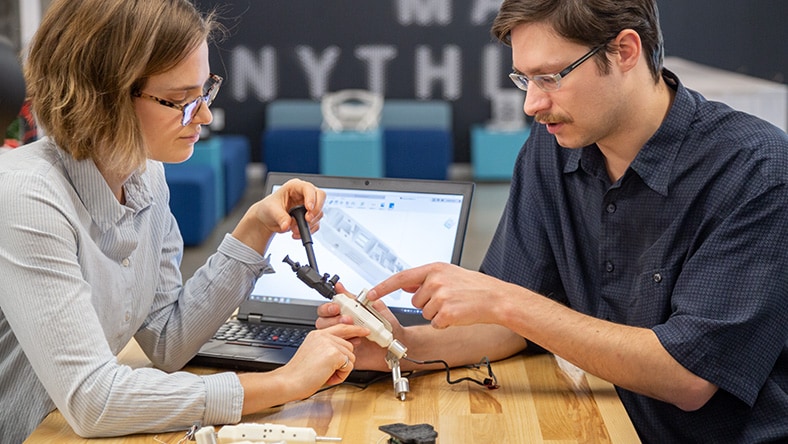

Medical device companies reverse engineer anatomy to create custom implants, prosthetics, and surgical tools. Scanning patient data and existing devices, they develop precise, personalized solutions that improve comfort, functionality, and healing outcomes while meeting strict medical standards.

Product developers analyze current designs to understand market solutions, improve ergonomics, and create compatible accessories. The reverse engineering process helps them identify opportunities for innovation, optimize manufacturing costs, and develop products that better serve user needs.

Designers use reverse engineering to capture intricate details of antique pieces, create precise molds, and develop complementary components. This enables them to preserve craftsmanship, reproduce complex patterns, and add modern features while maintaining aesthetic integrity.

3D scanning an automotive component helps reverse engineer older parts for reproduction or improvement, image by Mihajlo Maricic

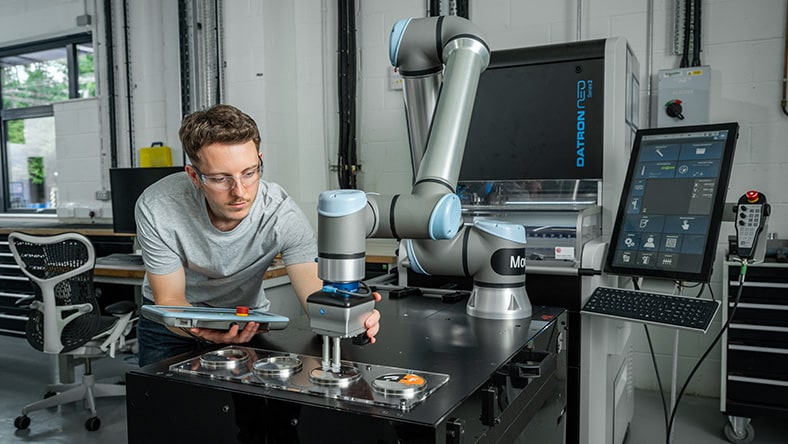

Reverse engineering hardware mainly involves creating a ‘digital twin’ of a physical object. Using advanced 3D CAD tools and software like Autodesk ReCap Pro, engineers transform real-world parts into detailed digital models they can analyze, modify, and improve.

When done legally and ethically, reverse engineering helps bridge the gap between the physical and digital worlds. Creators can redefine their existing designs while pushing innovation forward.

Modern reverse engineering for manufacturing hardware typically follows a multi-step process.

Engineers begin by scanning objects with advanced 3D equipment, generating intricate point clouds that capture every detail. Some projects use photogrammetry, combining multiple photographs to create detailed 3D models. Using software like Autodesk ReCap Pro, these scans transform into initial mesh models. Engineers gather additional measurements and test data to ensure a complete understanding of the original object.

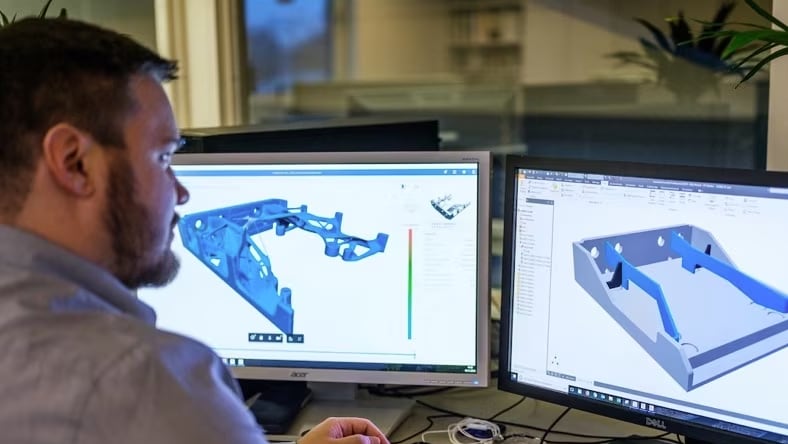

This critical phase transforms raw data into workable models. Engineers carefully clean and optimize the initial mesh models, removing imperfections and ensuring accuracy. Using software like Autodesk Fusion, these meshes convert into parametric models with precise, editable surfaces. The transformation creates a perfect digital replica that engineers can manipulate, analyze, and improve upon. The refined model becomes their canvas for innovation.

Now comes the exciting part — bringing improvements to life. Engineers meticulously compare their digital models against the original scans, ensuring they’re correct while identifying opportunities for enhancement. Advanced simulation tools test everything from structural integrity to performance optimization. Through iterative design improvements, the original concept evolves into something better. Physical prototypes provide real-world validation, and final testing confirms that all design goals are met, completing the journey from physical objects to improved design.

Engineers can choose from many reverse engineering tools and techniques to help them capture, refine, and enhance their designs. Here are some of the most common types.

3D scanners — using lasers, lights, or photogrammetry — create prices digital models. Tools like coordinate measuring machines (CMMs) capture exact dimensions, while digital calipers and material testing devices provide specific measurements and properties.

Software like Autodesk ReCap Pro turns scans into detailed 3D models, while Fusion 360 helps design new parts. Engineers can test and validate their designs through stress, flow, and thermal simulations.

Quality checks compare models to original specs, and automated systems generate technical drawings and manufacturing details.

Reverse engineering helps teams revive outdated parts, even without original design files. You can recreate these parts and even improve them, making them stronger and more efficient than before.

Reverse engineering software like Fusion offers time-saving tools, such as the Mesh Workspace for repairing and modifying models and Sketch tools for building profiles from mesh cross-sections, streamlining your workflow.

By speeding up R&D, reverse engineering helps engineers quickly gather insights on material choices and manufacturing methods, accelerating innovation.

Instead of starting from scratch, reverse engineering lets you update existing parts, cutting down on production costs and material waste while extending the life of products.

Reverse engineering opens up new design possibilities. Teams can tweak, refine, and adapt parts to meet specific needs or improve performance without constraints.

With quicker insights and more efficient workflows, companies can quickly bring improved products to market, staying ahead of the competition while keeping costs down.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

Claudius Peters

After using Fusion’s generative design to reimagine a crucial part for industrial cement coolers, Claudius Peters reverse-engineered the component back into Autodesk Inventor to validate a design that could be welded and cast.

Image courtesy of Claudius Peters

Soup Dragon

Engineers looking to break the human-powered land speed record reverse-engineered the Soup Dragon bicycle from analog designs into CAD data in Fusion, where they could refine the steering and other mechanical systems.

Marshall Prado

Biomimicry essentially reverse engineers the innate genius of natural structures, incorporating it into architecture and product design. Prado used Autodesk PowerMill to fabricate Filament Tower to mimic the high strength-to-weight ratio cellulose fiber structures of trees and other plants with carbon-and-glass fiber.

Image courtesy Marshall Prado/University of Tennessee Knoxville

Reverse engineering helped an Autodesk researcher optimize a lightweight airplane cabin seat frame, saving costs and reducing CO2 emissions

Reverse engineering and sustainability go hand-in-hand. Engineers can analyze how a product works and redesign it to be more eco-friendly without sacrificing functionality. This approach extends the lifespan of products by repairing or updating parts instead of replacing entire systems, reducing waste and conserving resources.

It also helps engineers create more sustainable designs by using fewer materials, adding recycled components, and making products easier to recycle. With reverse engineering software, these improvements can be simulated and tested before production, making sure you reach both your environmental and performance goals.

In renewable energy, reverse engineering improves the efficiency of solar panels and wind turbines. Engineers can work to make them more cost-effective and speed up the shift to clean energy solutions.

Combining reverse engineering with sustainable design principles enables companies to create better and more affordable products — proof that environmental responsibility and business success can go together.

Read more about how reverse engineering helps product design, helps re-create old printed circuit boards and other components, converts 2D drawings to 3D, and more.

A brief video demonstrates how to reverse engineer Autodesk Civil 3D project data from “legacy” drawings, particularly from DWG files.

This paper describes using a novel neural network for reverse engineering CAD shapes from other representations.

Reverse manufacturing is basically synonymous with reverse engineering, where someone deconstructs and analyzes a product or system to reveal how it was made or works. While software can be reverse-engineered, reverse manufacturing is more likely to refer to a hardware component or assembly.

The reverse manufacturing process includes disassembling the product into its parts and measuring the parts’ dimensions, for which 3D laser scanning can help. Next comes creating 3D CAD models of the parts, where the engineer can make modifications. Finally, engineers can manufacture the parts from their 3D models using 3D printing or other methods.

Reverse engineering applies to many industries, for both software and hardware. Software written to work only with one microprocessor or operating system can be reverse-engineered and remade to work with a different processor or OS. Malware often uses reverse-engineered code as a disguise, and cybersecurity often reverse-engineers malware to fight it.

The biomedical field reverse engineers proteins, organs, DNA, and more to study their functions. Notably, the Human Genome Project used reverse engineering to sequence human DNA.

Design and manufacturing use reverse engineering for many things, including large-scale projects like appliances, computers, and even vehicles, such as the Soviet MiG-25 “Foxbat” fighter jet, which was reverse-engineered after a Russian pilot defected and landed in Japan.

Reverse engineering as a practice is ethically neutral. People, however, can apply it ethically or unethically. Laws governing reverse engineering will vary by nation. In the US, reverse engineering is generally legal if the product was acquired legally and does not violate patent, copyright, or other laws and contracts.

Ethical applications of reverse engineering include those that bring back discontinued products, create interoperability with other products, and make significant improvements over the original. Besides violating laws and contracts, unethical uses of reverse engineering include creating knockoffs of existing products with shoddy quality and sometimes a deliberate attempt to obfuscate the products’ origin to confuse potential customers.

The reverse engineering steps, particularly for hardware, usually follow this order.

An engineer acquires data, often by disassembling a product and 3D-scanning its parts, which generates digital point clouds of the parts. The engineer may also test the parts to learn more about their design intent. During post-processing, the engineer converts the point clouds into mesh models with reverse engineering software and then manually edits the meshes.

Next, the mesh is converted to a parametric model with solid surfaces, where the engineer can make improvements and dimensional changes. Finally, the engineer reviews the models against the initial scans and may begin the iterative prototyping process.