& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Engineering data management is the process of handling, storing, organizing, and using data related to engineering projects and activities. This comprehensive approach includes the collection of data from various sources such as simulations, experiments, field measurements, and design documentation. Secure storage solutions, such as cloud storage, are used to make sure that data is easily accessible and protected. Organizing data in a logical and efficient manner, through categorization, indexing, and tagging, facilitates easy retrieval and analysis.

Engineering data management also involves integrating data from different sources to create a data set that supports comprehensive analysis and informed decision-making. Data analysis allows engineers to extract insights, perform calculations, and guide design and engineering decisions. Effective data sharing promotes collaboration by making sure that all stakeholders have access to the latest information. Extensive security measures protect data from unauthorized access, corruption, and loss, while compliance with industry standards and regulatory requirements is maintained.

Reduce the time and effort required to manage and retrieve data, with streamlined processes for improved productivity and quicker project completion.

Minimize errors that arise from outdated or incorrect information with engineering data management tools that help maintain consistency and integrity.

Ensure that everyone has access to the latest information and can work together more efficiently by easily sharing data among stakeholders.

Make smart decisions by using a comprehensive data set that engineers can use to make data-driven choices that optimize project outcomes.

Maintain the confidentiality and integrity of important information with engineering data management tools that protect sensitive data from unauthorized access and corruption.

Ensure adherence to industry standards and regulatory requirements with solutions that reduce the risk of non-compliance and associated penalties.

Reduce the chance of costly mistakes and rework by maintaining accurate and reliable data for a more efficient use of resources and budget.

Support the expansion of engineering projects with a scalable engineering data management solution that accommodates increasing amounts of data.

The engineering data management process is a systematic approach to handling, storing, organizing, and using data. Here are the key steps in the process:

Cloud-based product design software for manufacturing, 3D modeling, electronics, simulation, and data management

Boost collaboration and product development agility across your organization with Autodesk's engineering data management solutions.

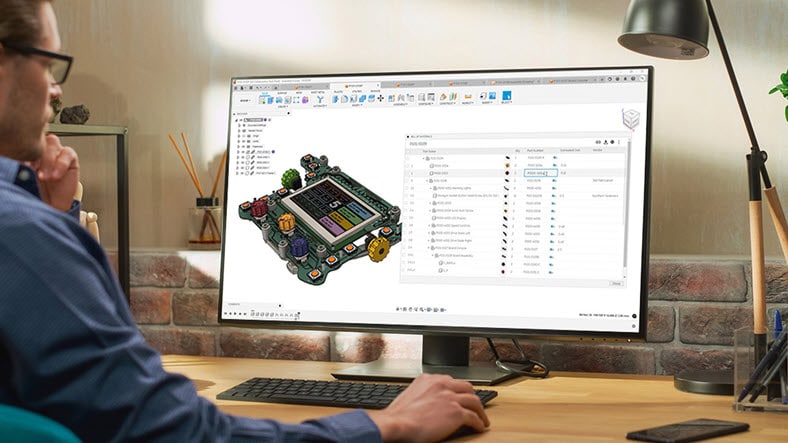

Autodesk Fusion is a cloud-based product development solution that includes built-in Product Data Management (PDM) along with CAD, CAM, CAE, and PCB capabilities.

It integrates data management seamlessly into team workflows from the beginning, eliminating the need for separate tools and complex configurations.

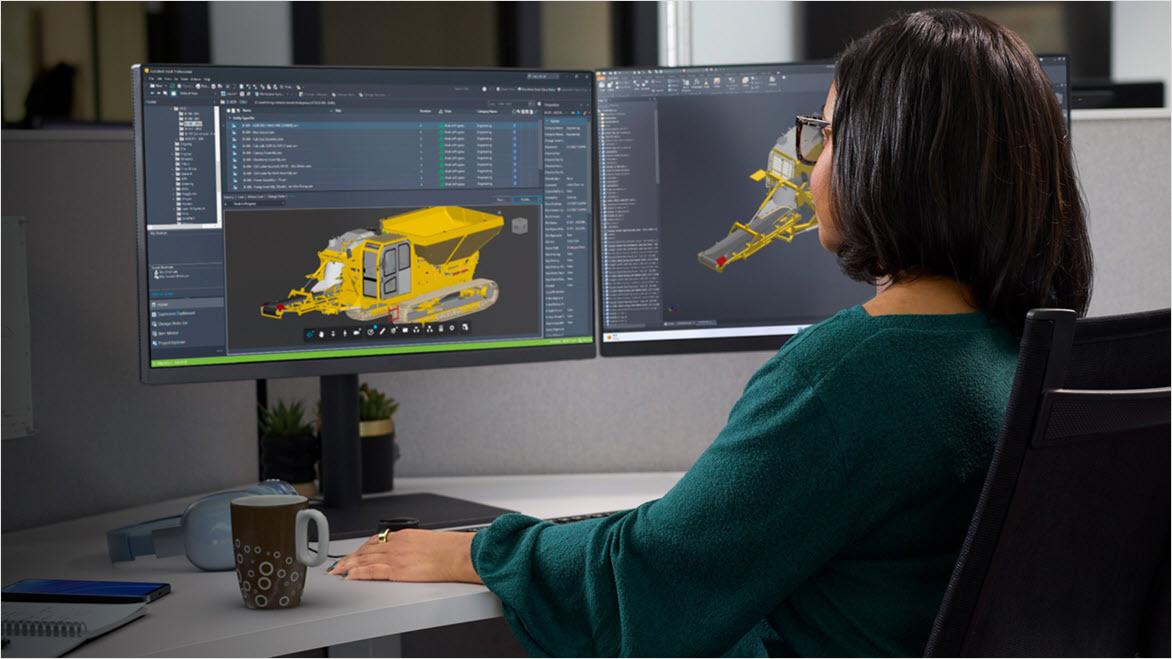

Autodesk Vault is an on-premise Product Data Management (PDM) solution that integrates with Autodesk design tools and other CAD systems, ensuring everyone works from a centralized source of organized data.

It provides team members with access to the most up-to-date information and optimized workflows to enhance productivity.

Access to organized and accurate data improves design quality, streamlines workflows, and improves decision making while leading to improved project outcomes.

Comprehensive data sets help monitor project progress, allocate resources efficiently, and help improve the completion time of tasks, reducing delays and added costs.

Perform analyses and inspections to make sure that products meet industry standards, while identifying and addressing issues early on in the manufacturing process.

Use data from prior projects to improve production processes and maintain a high-level of product quality, while reducing waste and operational costs.

Use accurate and up-to-date data to improve production processes, boost efficiency, and maintain consistent product quality, while reducing waste and operational costs.

Analyze data to understand market trends, customer needs, and product performance for more targeted marketing strategies and informed sales decisions.

Access historical data to predict equipment failures and schedule maintenance for operational continuity and reduced downtime.

Make data-driven financial decisions by analyzing costs, revenue projections, and resource allocation, leading to better budget management and financial planning.

Engineering data management and product lifecycle management (PLM) are complementary partners that work together to streamline the entire product development process. Engineering data managment focuses on engineering, providing secure and flexible data management during the design phase. It ensures that design data is stored in native formats, enhancing traceability and accommodating frequent design changes. Once the design is ready to manufacture, engineering data management provides a seamless transition by executing a release-to-manufacturing process and generating necessary documents. At this point, PLM takes over, handling the manufacturing phase by managing and tracing the manufacturing release package back to specific data management versions. This connection ensures smooth transitions between design and manufacturing, boosts productivity, and maintains critical traceability throughout the product's lifecycle.

Engineering data management is able to handle detailed projects, maintain regulatory adherence, and uphold stringent safety standards. It accurately tracks design modifications, materials, and component specifications.

In the automotive industry, managing engineering data is crucial for coordinating design, testing, and production. It also helps manage the lifecycle of vehicles from concept to production.

Engineering data management in construction improves collaboration among architects, engineers, and contractors. All project stakeholders have access to the latest plans and documents, reducing errors and delays.

For electronics and PCB design, data management tracks all design iterations and component specifications are accurately. This is necessary for maintaining product integrity and efficient manufacturing processes.

Engineering data management helps in maintaining infrastructure, maintaining compliance with regulations, and optimizing operations. It also effectively tracks maintenance schedules and system upgrades.

Managing engineering data in healthcare ensures that medical devices are designed to meet stringent regulatory standards. It provides the documentation of design changes and makes sure that all stakeholders have access to accurate data.

As technology continues to evolve, future trends in engineering data management are set the change the way organizations handle and use data.

Emerging trends shaping the future:

Artificial intelligence (AI) and machine learning (ML)

IoT devices

Cloud-based data management solutions

Advanced data analytics and visualization

Data management will continue to become more efficient, insightful, and secure to drive innovation across manufacturing.

Engineering data management is the process of managing and organizing engineering data, including design documents, specifications, and materials, to maintain accuracy, traceability, and accessibility throughout the product lifecycle.

Engineering data management helps maintain data integrity, boosts collaboration, improves efficiency, and ensures compliance with industry standards and regulations.

Engineering data management improves productivity by streamlining workflows, reducing manual data entry, making sure that the latest design information is accessible to all stakeholders, and efficiently tracks design changes.

Engineering data managment systems implement access controls, encryption, user authentication, and audit trails to protect sensitive engineering data from unauthorized access and modifications.

Electronic data management supports regulatory compliance by maintaining accurate records of design changes, accurately tracks materials and components, and provides necessary documentation for audits and certifications.

Cloud-based engineering data management systems, like Autodesk Fusion offer benefits such as remote access to data, scalability, reduced IT infrastructure costs, real-time collaboration, and automatic updates, improving overall efficiency and flexibility for engineering teams.