& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

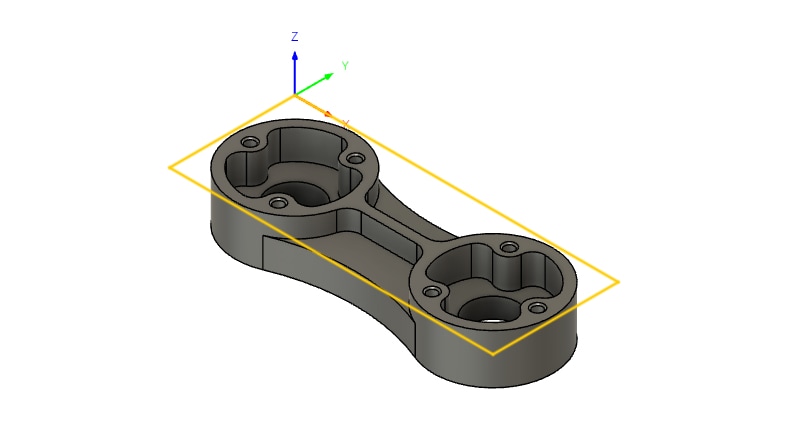

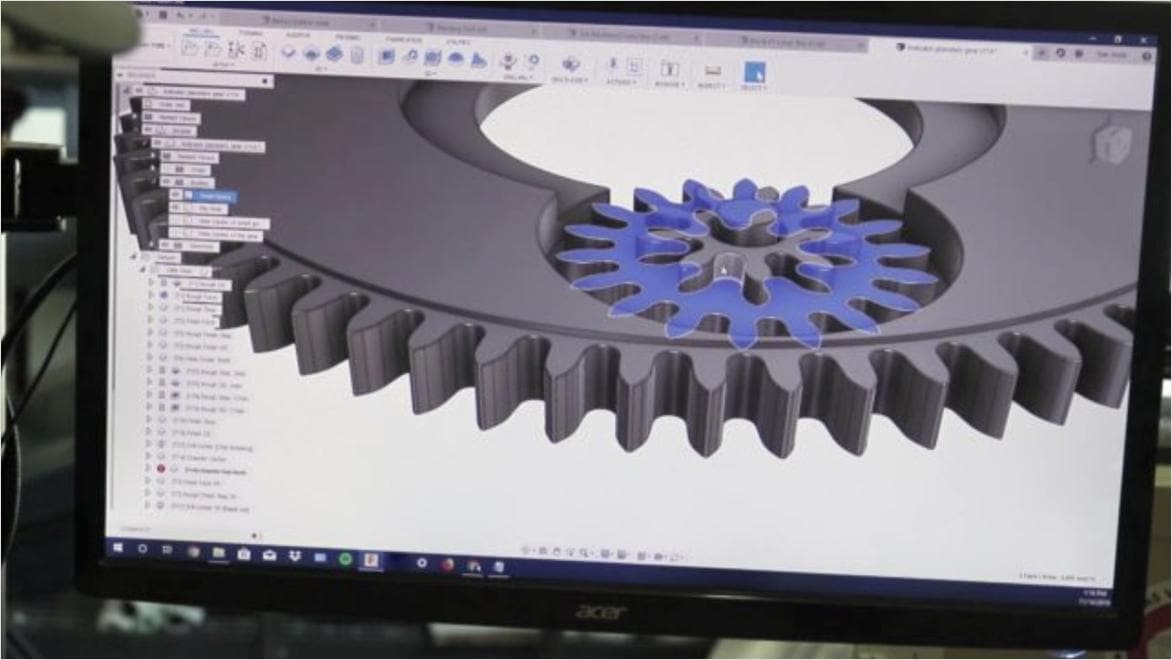

Professional CAD/CAM tools built on Inventor and AutoCAD

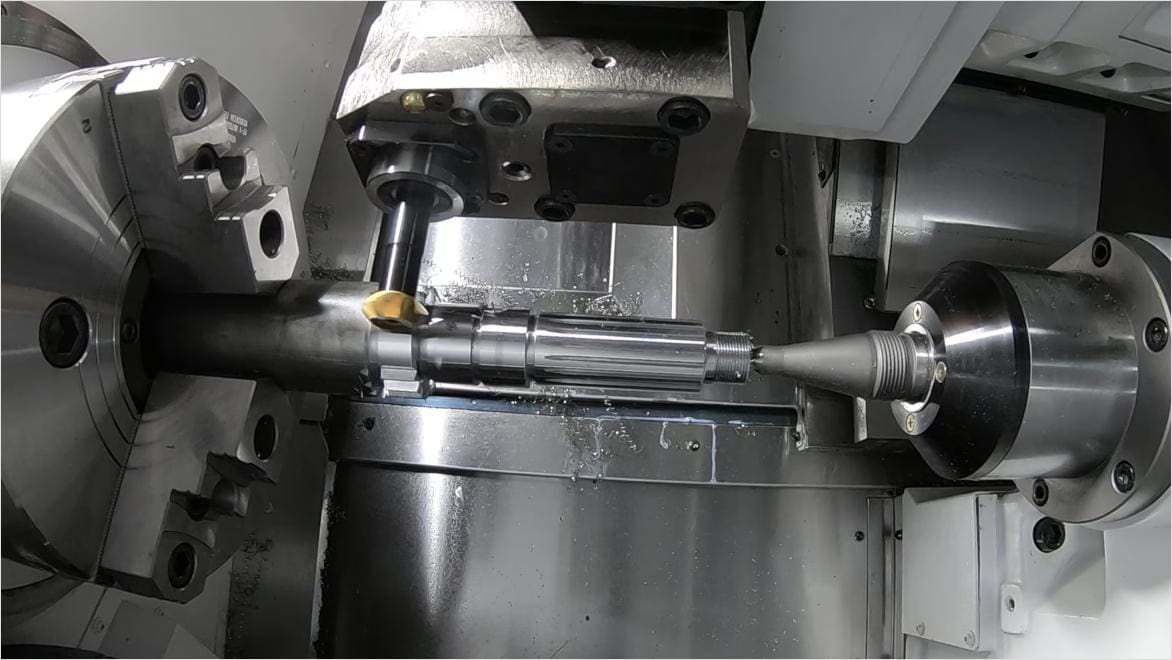

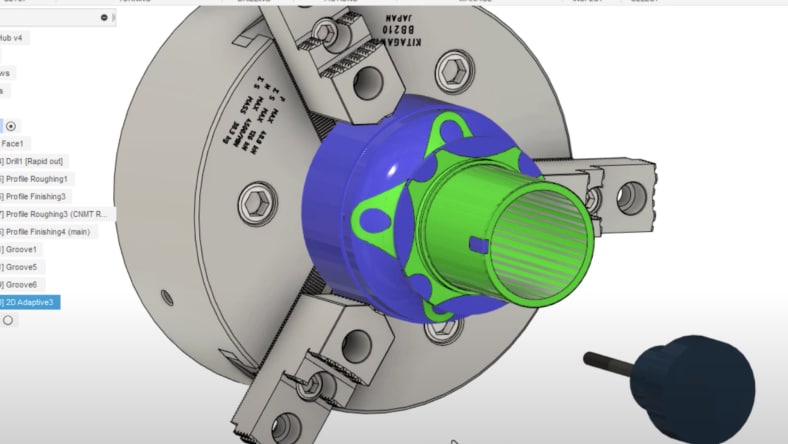

Mill-turning is a hybrid machining process that combines milling and turning operations within a single machine, allowing for the production of complex parts with both rotational and prismatic features. This process typically involves the use of a CNC (Computer Numerical Control) machine that can perform multiple tasks such as drilling, tapping, milling, and turning without the need to transfer the workpiece to different machines. The integration of these operations in one machine reduces setup times, improves precision, and enhances overall productivity by streamlining the manufacturing process.

The primary advantage of mill-turning is its ability to produce intricate and high-precision parts in a single setup. By combining milling and turning, manufacturers can achieve tighter tolerances and better surface finishes while reducing the risk of errors and inconsistencies that may arise from multiple setups.

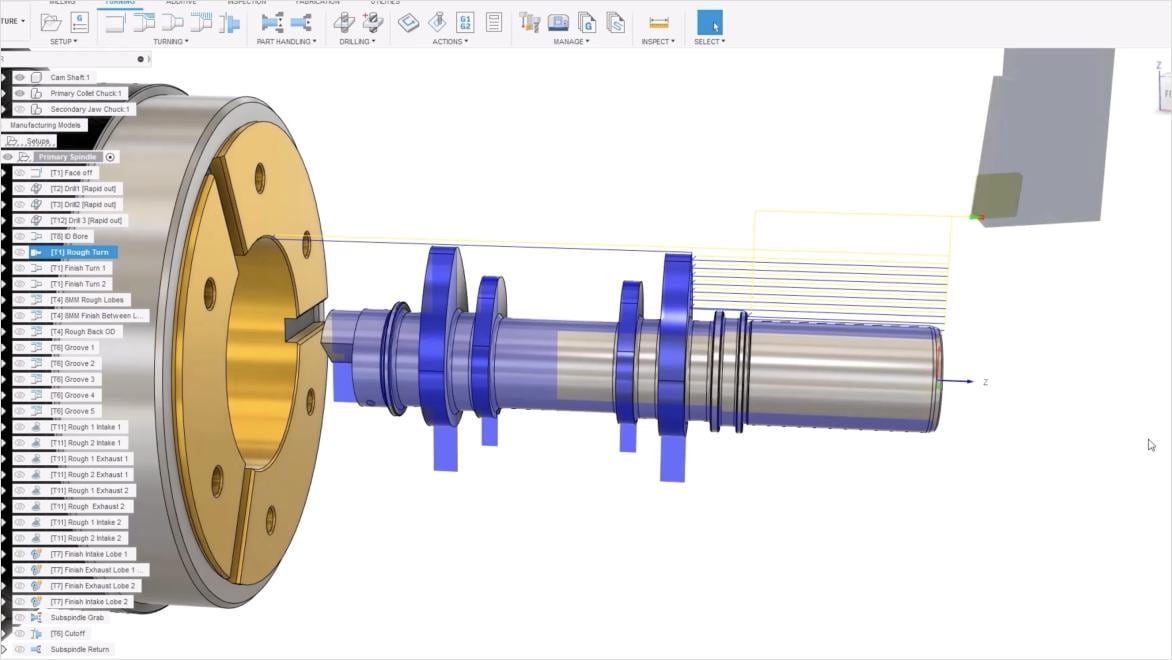

Mill-turn software is designed to optimize machining sequences, automate toolpaths, and ensure seamless transitions between milling and turning operations. Advanced features like sub-spindles enable continuous part transfers, allowing simultaneous machining on both ends. This results in faster cycle times, reduced errors, and significant cost savings, making mill-turn technology essential for high-precision manufacturing.

The benefits of mill-turn software for CNC milling, include:

Streamlining the design-to-manufacturing process for users, reducing complexities, and enhancing overall workflow efficiency.

Ensuring the production of intricate parts with tight tolerances and meeting high standards.

Combining milling and turning operations in a single software solution, users experience a significant reduction in setup times, enabling faster and more efficient machining processes.

Mill-turning software optimizes toolpaths and automates tasks, leading to heightened productivity levels.

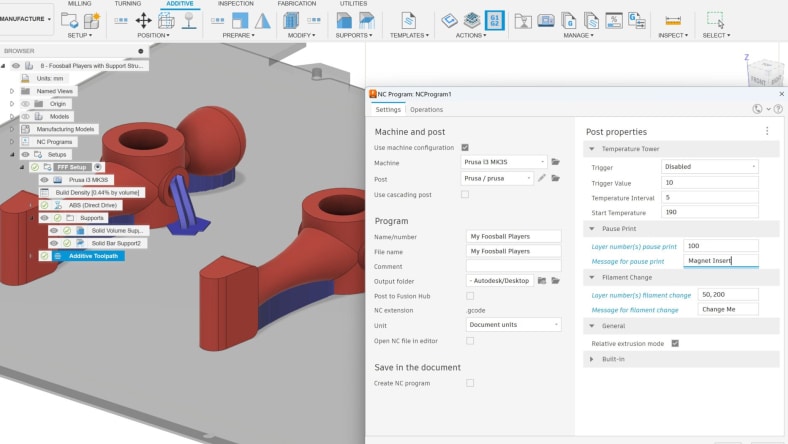

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Unlock efficiency and precision with Fusion’s integrated mill-turn capabilities—seamlessly program complex parts, reduce setups, and optimize machining workflows."

Integrated design and machining

Multi-axis machining precision

Streamlined mill-turning workflows

This section will outline the key differences between CNC turning and CNC milling, explaining their processes, ideal applications, and when to choose each for specific part designs.

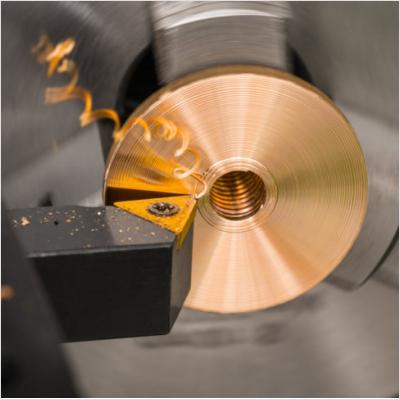

CNC turning involves rotating the workpiece while the cutting tool remains stationary. The part is held in a chuck and spins as tools cut away material to create round or cylindrical shapes.

CNC milling involves a stationary workpiece while the cutting tool moves to remove material. The part is clamped on the machine bed, and the tool moves in various directions to shape the material.

Explore how Fusion’s advanced tools enhance CNC mill-turning, streamlining design optimization, improving machining efficiency, and ensuring precise results for complex parts.

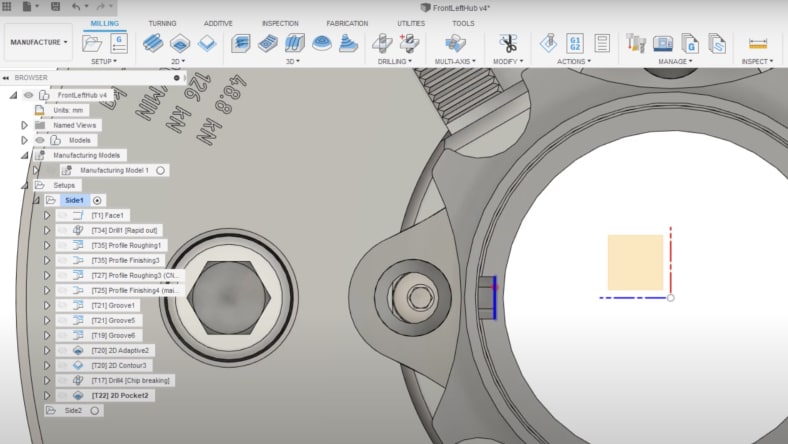

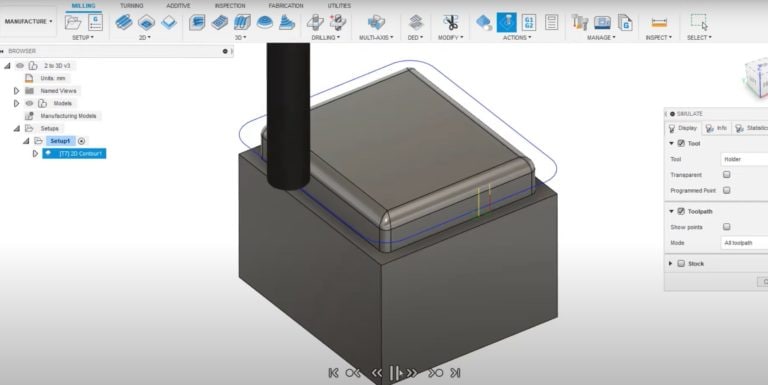

The turning toolpath simplifies the creation of turning operations, offering optimal paths for part shaping. It automatically adjusts feeds, speeds, and toolpaths for smooth, precise cuts.

The milling toolpath provides flexible strategies for milling operations. It supports 2D and 3D milling, ensuring accurate and efficient machining of complex geometries for mill-turn machines.

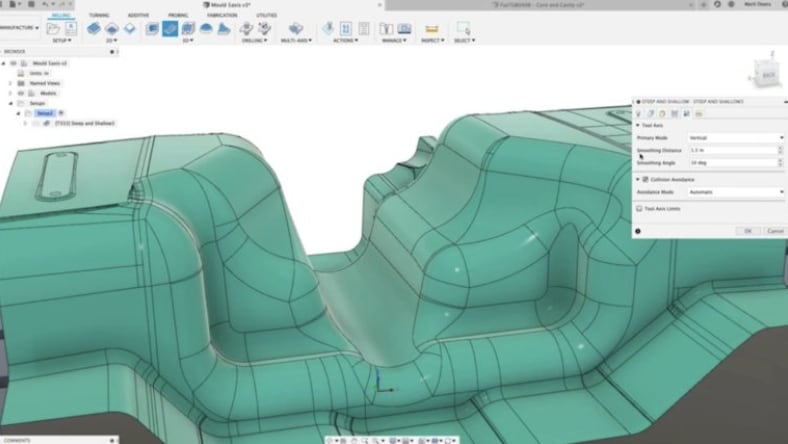

This tool supports multi-axis machining, allowing operators to perform complex geometries with advanced machine setups. It enhances precision, reduces cycle times, and improves part quality.

CAM integrates seamlessly with milling and turning operations, providing efficient toolpath creation, simulation, and optimization for both complex and simple part designs.

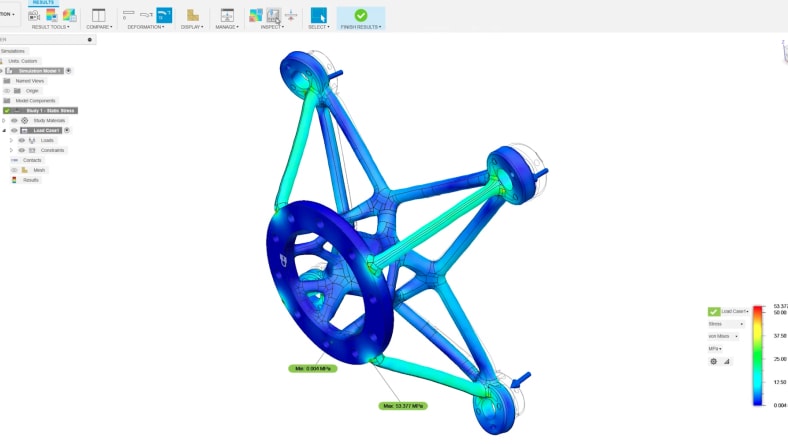

Fusion’s simulation tools allow users to virtually verify machining operations. It helps prevent errors by simulating both turning and milling processes to ensure a flawless manufacturing workflow.

Adaptive clearing maximizes material removal rates while maintaining tool life and part accuracy. This strategy reduces machining time and optimizes tool engagement during both turning and milling.

Fusion offers a variety of toolpath strategies tailored for specific part features. These strategies include roughing, finishing, and contouring, which adapt to different geometries for superior efficiency.

Fusion automatically generates machine-ready G-code for mill-turn setups. The post-processing feature ensures that the code is optimized for machine compatibility, reducing setup time and machining errors.

Experience the power of Fusion for mill-turn operations with a 30-day free trial. Optimize designs, streamline workflows, and boost efficiency—no cost, just results!

Mill-turning software is crucial for streamlining complex manufacturing processes, combining both milling and turning into one integrated workflow. It enhances precision, reduces setup time, and improves overall productivity. With the ability to handle multi-axis machining, the software allows for more intricate geometries and part designs that would be difficult to achieve using traditional methods. It also enables seamless toolpath generation, error minimization, and optimization of machining cycles. This reduces waste, increases throughput, and ultimately results in higher-quality parts in less time, making it an essential tool for modern manufacturing projects.

See how our customers leverage mill-turn programming to drive efficiency and innovation.

Read about how Vortic Watch Company uses Autodesk Fusion and CNC machines to convert WWII-era pocket watches into custom wristwatches, streamlining design and manufacturing for unique, high-quality timepieces.

Read about how Okra Solar uses Autodesk Fusion to design their solar pods, which provide affordable and reliable electricity to off-grid communities, connecting two million people to clean power by 2025.

Read about how KISKA modernized classic motorcycle design using mill-turn machining and Autodesk Alias, blending minimalism with advanced engineering to create the sleek, high-performance SVARTPILEN and VITPILEN models.

Complex toolpath generation

Tool wear and maintenance

Part setup and alignment

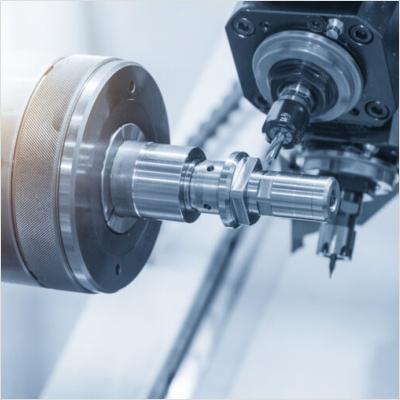

CNC mill-turn programming combines milling and turning operations into one setup, reducing setup time and part handling. By using both tools on a single machine, complex geometries are produced faster and more accurately. Advanced programming tools, like those in Autodesk Fusion, optimize toolpaths to minimize downtime and improve precision. This integrated approach leads to faster production, fewer errors, and greater efficiency.

Explore the essential CNC milling tools to enhance your design and manufacturing processes. From end mills to reamers, discover which tools boost performance and precision with Autodesk Fusion!

Unlock the full potential of CNC programming with G-code fundamentals, essential for mastering part production. Learn how to optimize your machining processes with the right G-code instructions.

Elevate your manufacturing process with Autodesk Fusion’s 4-axis CNC milling. Boost precision, flexibility, and efficiency for complex workflows in your production setup.

Switch from EDM to faster CNC milling with Autodesk Fusion. Improve mold making efficiency, reduce delivery times, and leverage advanced machining for deep areas and complex geometry.

Unlock precision CNC machining with Autodesk Fusion. Simplify coordinate systems, streamline tool management, and enhance design accuracy for smoother manufacturing processes.

Discover how cloud-based CAD + CAM solutions, like Autodesk Fusion, simplify collaboration, eliminate data issues, automate workflows, and boost efficiency across design and manufacturing teams.

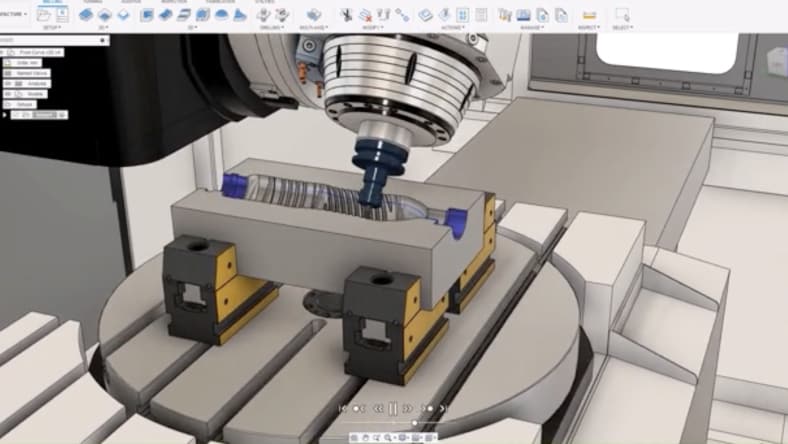

Mill-turn machines combine both milling and turning capabilities into a single setup, improving efficiency and precision. These machines enable users to perform complex part geometries in fewer operations, reducing handling time and the risk of errors. Autodesk Fusion plays a significant role in optimizing mill-turn operations by providing seamless integration for both design and machining. With its advanced CAM features, Fusion simplifies toolpath creation, improves part accuracy, and streamlines the overall workflow.

Milling machines are versatile tools used for a variety of manufacturing tasks:

Autodesk Fusion’s integrated CAD and CAM capabilities can be used to create precise milling paths for these tasks, optimizing machining time and improving overall part quality.

The cost of mill-turn software can vary depending on the features, the level of integration, and the type of machine supported. On average, mill-turn software can range from a few thousand dollars for entry-level software to tens of thousands of dollars for high-end solutions with advanced capabilities. Autodesk Fusion offers a more affordable subscription model, with all-in-one design, engineering, and manufacturing tools included, making it a cost-effective choice for both small businesses and large enterprises. Fusion’s subscription model is designed to be scalable, making it accessible to a wide range of users. Learn more about Fusion and its pricing here.

Turning and milling are both subtractive manufacturing processes, but they differ in how the material is removed.

Autodesk Fusion allows users to easily switch between turning and milling operations in a unified platform, offering both machining options for more complex multi-operation projects. Learn more here.

Mill-turn machines come in various configurations, each suited for different types of workpieces:

CAM (Computer-Aided Manufacturing) software is essential for generating toolpaths, simulating machining processes, and optimizing the use of mill-turn machines. Autodesk Fusion’s CAM module helps simplify the programming of mill-turn machines by allowing users to create integrated toolpaths for both milling and turning operations. This results in higher precision, less manual programming, and reduced cycle times, improving overall productivity.

The right mill-turn machine depends on several factors, including:

Yes! Autodesk Fusion supports multi-axis mill-turn machining, allowing you to create more complex toolpaths for intricate part geometries. The software’s powerful CAM tools allow you to program simultaneous movements of both the lathe and mill components, enhancing part accuracy while reducing production time.

Integrating CAD and CAM software provides a seamless workflow from design to manufacturing. By using Autodesk Fusion , you eliminate the need for separate systems, reducing errors and data transfer issues. This integration allows for faster iterations, optimized toolpaths, and better communication between design and production teams.