& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Engineering change management is a structured approach to managing changes in products, processes, or systems. It includes the identification, documentation, evaluation, and implementation of changes. This aids in making sure that changes are managed correctly and don't negatively impact the final product.

Engineering change management aims to maintain consistency and quality by making sure that any changes are assessed and communicated to all relevant departments and stakeholders. With a structured engineering change management process, companies have fewer errors, lower costs, and improved efficiency. Even collaboration and coordination among your teams improves for smarter decision-making and timely project delivery.

Engineering change management software streamlines the change process, driving these key benefits:

Easily track all changes and maintain detailed records for future reference.

Automate engineering change management to reduce manual work and accelerate workflows.

Improve team and department collaboration with engineering change management software.

Identify risks early-on, so that changes can be made quickly to minimize long-term impact.

Reduce the costs that arise when there are errors and inefficiencies during the change process.

Make more intelligent decisions with the ability to see the impact of engineering changes in one place.

Make sure changes are made with minimal impact while maintaining high-quality standards.

Grow your product portfolio with a scalable data management solution that supports growing data.

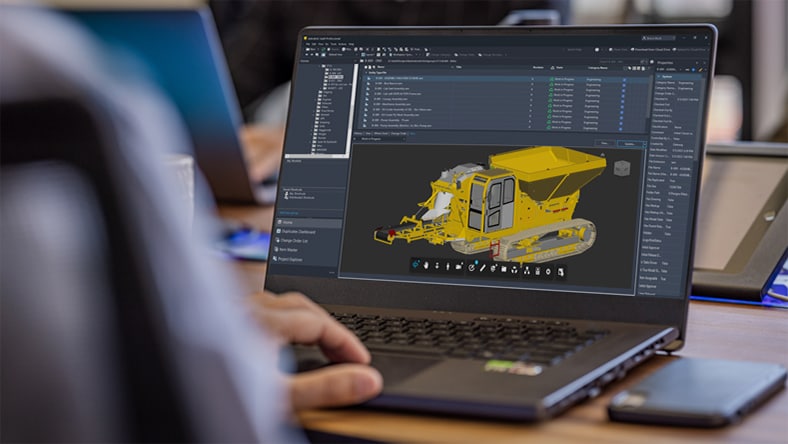

Manage engineering changes in one system—accept requests online, track orders end-to-end, and maintain full visibility, traceability, and compliance with complete audit trails.

Automate change notifications, assign tasks with built-in scheduling, and use configurable workflows to speed up ECO closure and fit your business needs.

Maintain comprehensive, real-time audit trails and traceability of changes, integrating change management with quality processes for complete oversight and compliance.

Analyze change impacts across products, processes, and teams to identify risks and resource needs, ensuring smooth execution and continuous improvement.

Boost collaboration and product development agility across your organization with Autodesk's engineering change management solutions.

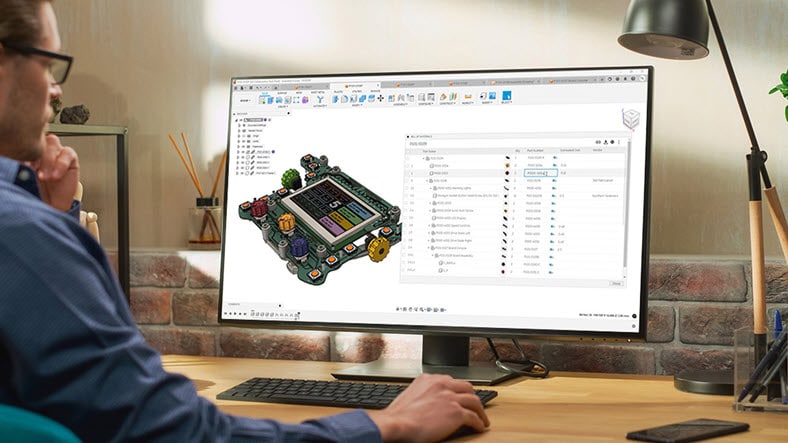

Autodesk Fusion is a cloud-based product development solution that includes built-in product data management along with CAD, CAM, CAE, and PCB capabilities.

It integrates data management seamlessly into team workflows from the beginning, eliminating the need for separate tools and complex configurations.

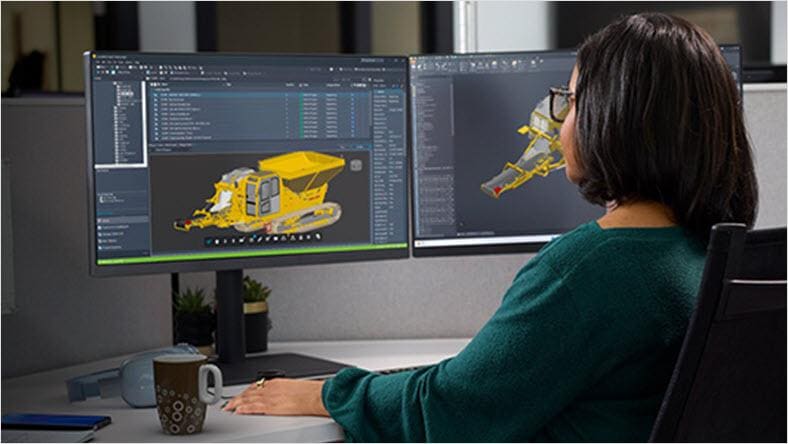

Autodesk Vault is an on-premise product data management solution that integrates with Autodesk design tools and other CAD systems, ensuring everyone works from a centralized source of organized data.

It provides team members with access to the most up-to-date information and optimized workflows to enhance productivity.

The engineering change management process is a systematic approach to managing changes in engineering projects so that all modifications are documented, evaluated, and implemented effectively. Here are the primary steps in the process:

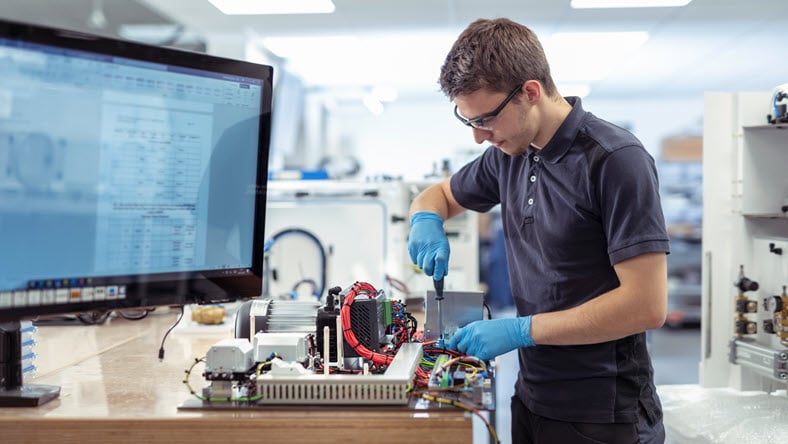

Thoroughly review, validate, and document design changes, to improve communication to manufacturing and other departments.

Reduce errors and improve the allocation of resources and scheduling, minimize downtime, and maximize efficiency with engineering change management.

Improve quality control with thorough testing and validation, while maintaining compliance with industry standards.

Manage inventory levels and procurement plans according to updated requirements with engineering change management software.

Gain a structured approach to change implementation that improve project timelines, and resource and risk management while improving decision-making.

Quickly adapt to market demands and customer feedback, ensuring the accurate communication of the latest product information to customers and stakeholders.

Provide accurate and timely information to customers about product updates and changes. Improve customer satisfaction by with product consistency and quality.

Track the financial impact of changes for better budgeting and cost control, while supporting cost-saving initiatives by reducing errors and rework in manufacturing.

Engineering change management is a game-changer across many industries, helping them manage changes smoothly and efficiently. Here are some examples of how it can make a significant difference:

Engineering data management helps make sure that every change is documented and validated to meet the strict aviation regulatory requirements.

Engineering change management helps track design and production changes to make sure cars are safe and that manufacturers can quickly adapt to market changes.

Manage changes in project plans, materials, and designs to ensure timely and on-budget completion, while facilitating smooth collaboration between architects, engineers, contractors, and clients.

Quickly adapt to new technological advances and consumer demands by managing updates and new product designs and features.

Handle changes in product design, packaging, and marketing to keep up with consumer preferences and trends, ensuring timely updates and accurate communication to retailers and consumers.

Manages changes in medical devices, equipment, and procedures to ensure patient safety and regulatory compliance, while supporting continuous improvement in healthcare delivery and services.

Future trends in engineering change management are likely to focus on increased automation, enhanced data analytics, greater integration with digital tools, and improved collaboration. Here are some key trends to watch:

Emerging trends shaping the future:

Engineering change management will continue to become more efficient, accurate, and collaborative to help companies adapt quickly to changes.

Engineering change management is important for maintaining product quality and reducing errors by systematically tracking and validating changes. It improves operational efficiency and boosts collaboration among departments, so that everyone is aligned and informed. It also supports compliance with regulatory requirements and industry standards through thorough documentation.

Manufacturers need engineering change management software to streamline and optimize their change processes, maintaining product quality and consistency. The software helps systematically track, document, and validate changes, reducing the risk of errors and costly rework. It enhances operational efficiency by providing structured workflows and real-time collaboration tools, ensuring all departments are aligned and informed.

An engineering change request (ECR) is the initial proposal for a change, detailing the issue, suggested modifications, and the rationale behind the change. It's typically submitted by individuals or teams identifying the need for a change and seeking approval to proceed.

An engineering change notice (ECN), is issued after the ECR has been reviewed and approved. It provides formal documentation of the approved change, including detailed instructions for implementation, affected items, and timelines.

An engineering change request (ECR) is the initial proposal for a change, outlining the identified issue, suggested modifications, and the justification for the change. It serves as a request for approval to consider and evaluate the proposed change.

An engineering change order (ECO) is created after the ECR has been reviewed and approved. The ECO provides detailed instructions for implementing the approved change, specifying the affected items, steps to be taken, responsible parties, and timelines.

Engineering change management (ECM) helps make sure that changes to products, processes, and materials are systematically evaluated for their environmental impact. It helps organizations implement eco-friendly modifications, reduce waste, and optimize resource usage. Engineering change managemenet also facilitates compliance with environmental regulations and sustainability standards through thorough documentation and validation.