& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

CNC milling is a machining process that uses computer numerical control to operate milling machines. These machines have rotary cutters that remove material from a workpiece, creating intricate shapes and designs with a high level of precision. The CNC system interprets a digital design file, typically in the form of CAD/CAM software, and translates it into specific commands that guide the milling machine's movements.

This process can handle a wide variety of materials, including metals, plastics, and wood, making it versatile for various applications. CNC milling is widely used for its ability to produce complex geometries and fine details that are challenging to achieve manually.

CNC milling machines operate with high precision, so that each part produced meets exact specifications and tolerances. This level of accuracy is critical for industries such as aerospace, automotive, and medical devices, where minor variations can have significant consequences.

By automating the machining process, CNC milling reduces the need for manual intervention, allowing for continuous operation and faster production cycles. This leads to lower labor costs and quicker turnaround times.

CNC milling provides consistent and repeatable results. Once a design file is programmed, the machine can produce identical parts over and over again. This helps maintain quality control in mass production and uniformity across batches.

CNC milling machines can handle a wide range of materials and create complex geometries and intricate details. This versatility allows for the production of parts that would be difficult to achieve with manual machining.

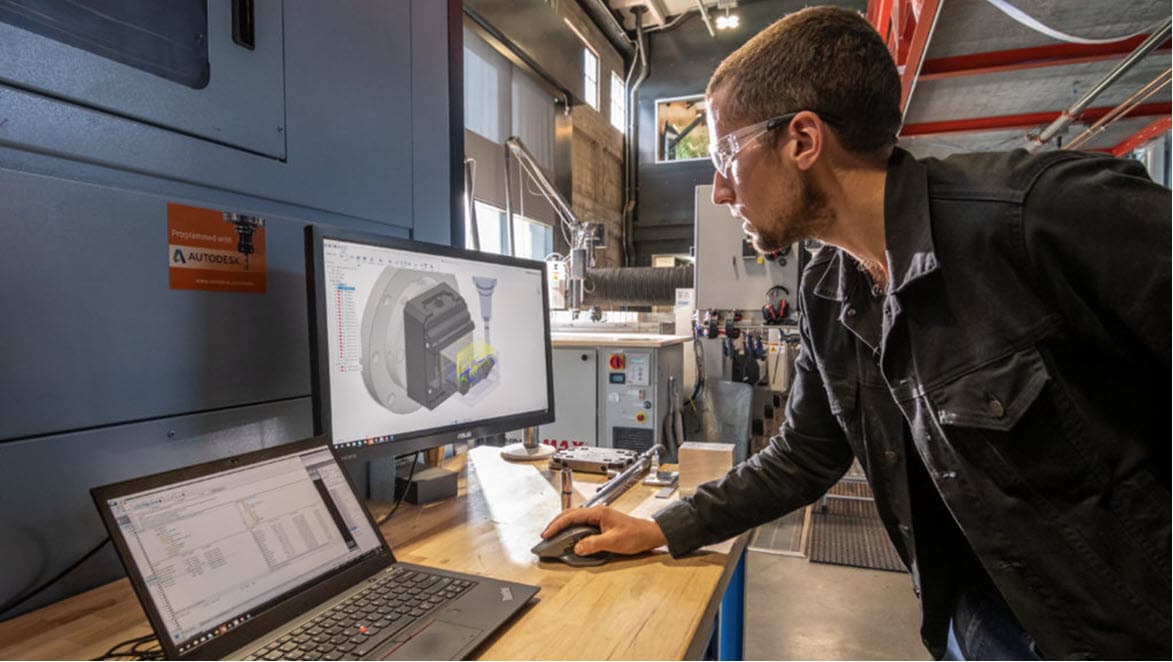

Fusion for Manufacturing is a complete cloud-based solution that integrates CAD, CAM, and CAE, with built-in PDM tools. Start streamlining workflows, reducing costs, enhancing product quality, and driving innovation.

Fusion seamlessly integrates CAD and CAM so that you can design and generate toolpaths smoothly, without switching between different tools.

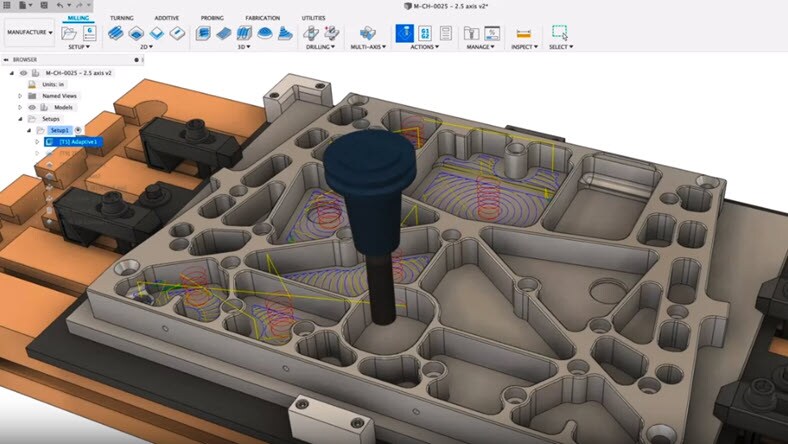

Optimize toolpaths to efficiently remove material, reduce machining time and tool wear, while maintaining high precision.

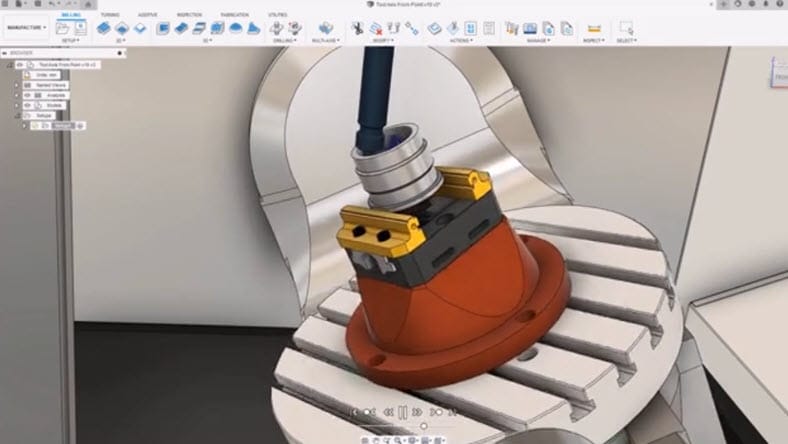

Gain access to flexible toolpath generation with options including 2D, 3D, multi-axis, and surface milling to address diverse and complex manufacturing needs.

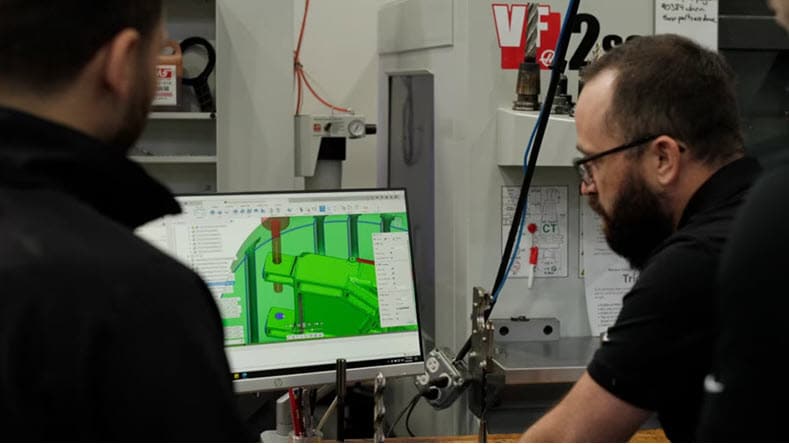

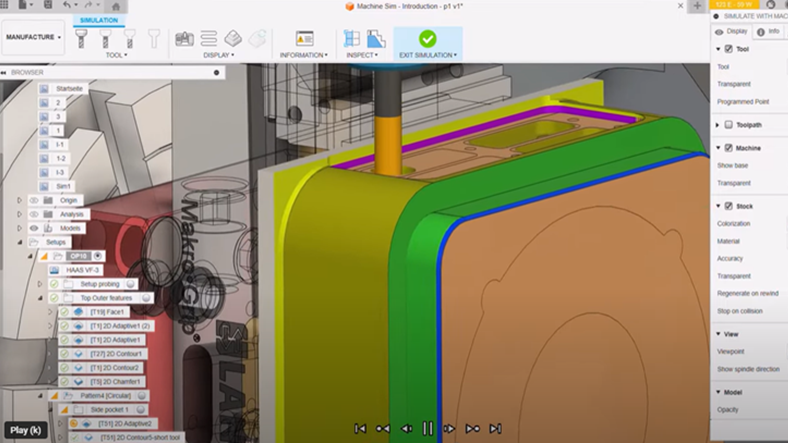

Simulate machining operations to visualize tool movements, detect issues, and verify toolpath accuracy before to machining to minimize errors and waste.

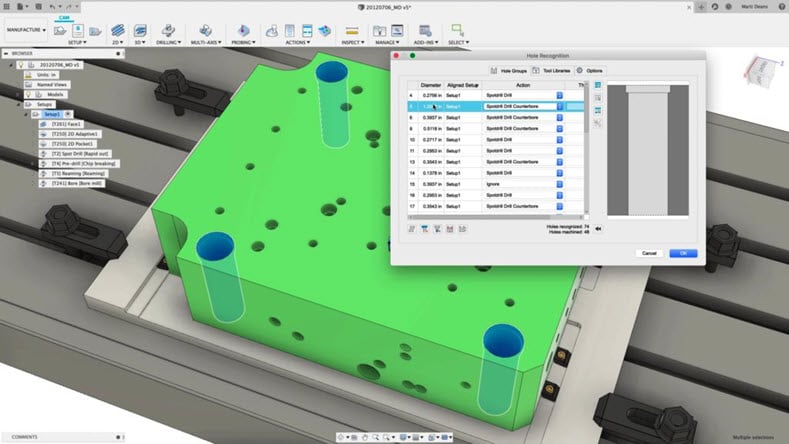

Automatically detect holes, pockets, and contours, and suggest appropriate machining strategies to simplify the programming process and increase efficiency.

Enable real-time collaboration, with access to version control, and secure data management, so that teams can work together seamlessly regardless of their location.

Learn about key differences between CNC milling and CNC turning, explaining their processes, ideal applications, and when to choose each for specific part designs.

In CNC milling, the workpiece is held stationary while the cutting tool rotates and moves along multiple axes (typically three to five), cutting away material to shape the part. This process is best suited for creating complex geometries, intricate details, and various surface features such as holes, slots, and contours. Milling machines can handle a wide range of materials, including metals, plastics, and composites, and are commonly used in industries like aerospace, automotive, and medical device manufacturing.

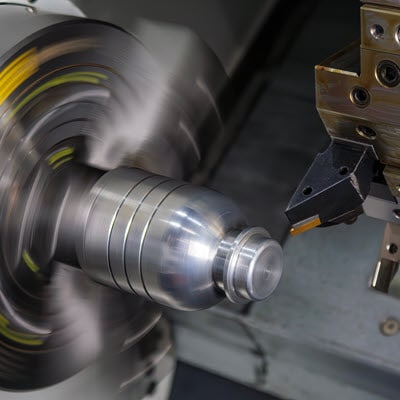

CNC turning involves rotating the workpiece while a stationary cutting tool moves along one or two axes to remove material. This process is best suited for producing symmetrical, round parts such as shafts, cylinders, and threaded components. Turning machines, also known as lathes, are highly beneficial for creating precise cylindrical shapes and are often used in the production of components like bolts, screws, and fittings. CNC turning is widely used in industries that require high-volume production of round parts, such as automotive, and oil and gas.

Maintain precision, efficiency, and produce high-quality parts during the CNC milling process, by following these steps:

The first step involves creating a detailed digital model using CAD software. The model should include all necessary dimensions and features of the part to be manufactured.

The CAD model is then converted into a CNC program using CAM software. This program, often in the form of g-code, contains the instructions for the CNC machine to follow such as tool path, cutting speeds, and feed rates.

Prepare the CNC machine by loading the required tools, securing the workpiece, and setting up the machine parameters according to the CNC program.

Run the CNC machine to perform the milling operation. The machine follows the instructions from the CNC program to cut, drill, or shape the workpiece.

These popular CNC milling methods are widely used due to their effectiveness, versatility, and ability to produce high-quality results in various machining tasks.

Face milling is used for creating smooth finishes on large, flat surfaces. It is effective at removing material quickly and for preparing workpieces with flat faces, making it a staple in many machining applications.

Peripheral milling is a valuable method for machining the sides of a workpiece and creating deep slots, contours, and complex profiles. Its versatility in shaping the edges and sides of parts makes it a common choice in various industries.

Pocket milling is great for creating cavities or pockets within a workpiece. This technique is necessary for machining internal features such as recesses and slots, making it indispensable for parts that require internal detailing.

Profile milling is used to machine the outer contour of a part to a specific shape or design. This method creates intricate shapes and patterns on the edges of a workpiece. It includes curves and complex geometries, making it a popular solution for precision machining.

CNC milling machines are incredibly versatile and can produce a range of parts for multiple industries. From more simple components like brackets, gears, and housings to intricate pieces like engine blocks, turbine blades, and detailed molds, these machines handle it all with ease. In aerospace, they craft lightweight yet robust structural parts, while in the medical field, they produce precise implants and surgical instruments.

Automotive manufacturers rely on CNC milling for engine parts, transmission cases, and sleek prototypes, while electronics benefit from finely milled heat sinks and circuit board enclosures. The ability to mill different materials, including metals, plastics, and composites, further increases the scope of parts that can be manufactured using CNC milling technology.

Take a deep dive into CNC turning vs. CNC milling to determine which option best fits your process.

Learn the basics of the CNC coordinate system, including the Cartesian coordinate system, work coordinate system (WCS), and offsets.

Explore the merits of 4-axis further, looking especially at its role in mill-turning.

Learn the basics of when and how to use a milling machine in your Fusion workflows.

Take a closer look at the differences between horizontal vs. vertical CNC milling machines to discover which is right for your business.

Learn what you should look for when you shop for a 5-axis CNC mill for mold making.

CNC stands for computer numerical control in milling. It refers to the automated control of machining tools (such as drills, lathes, mills, and 3D printers) with a computer executing pre-programmed sequences of machine control commands. This technology allows for precise and efficient manufacturing of complex parts.

A CNC milling machine typically operates along three primary axes of motion. Some advanced machines may include additional axes for more complex operations. Here are the primary axes:

Advanced CNC milling machines may also include additional axes, such as:

CNC milling produces high-quality parts by using precision, consistency, and efficiency. The automated nature of CNC machines ensures exact movements and reduces human error, resulting in parts that match design specifications with minimal variation. CNC milling machines help to create complex geometries and intricate details while optimizing material usage, reducing waste, and cutting production time. Advanced monitoring systems enhance quality control, so each part meets high standards.

G-code is the programming language used to control CNC machines. It consists of a series of commands that guide the machine's movements and operations, such as cutting, drilling, and finishing. Each G-code command specifies a particular action. In CNC milling, G-code is used to:

Workpiece holding is important in CNC machining to maintain stability and precision, preventing movement or vibrations that could lead to inaccuracies and known issues. It improves safety by minimizing the risk of the workpiece slipping or being ejected during machining. Securely held workpieces allow for consistent quality across multiple parts and optimized tool performance, leading to longer tool life, and efficient material removal. Effective work holding solutions also allow for more complex and intricate machining operations, maintaining precision and flexibility.

CNC milling machines are versatile and can produce a wide range of parts with varying complexity and precision. They are commonly used to manufacture components for industries such as aerospace, automotive, medical, and electronics. Examples include engine parts, such as cylinder heads and turbochargers, complex medical implants, precision gears, and electronic enclosures. CNC milling can create detailed molds and dies for injection molding and extrusion processes, as well as custom prototypes and one-off pieces for specialized applications. The flexibility to work with different materials, including metals, plastics, and composites, expands the variety of parts that CNC milling machines can produce.

A CNC milling machine is an automated machining tool that uses computer-controlled commands to precisely remove material from a workpiece, creating complex shapes and designs. Using rotating cutting tools that move along multiple axes, CNC milling machines work with various materials, including metals, plastics, and composites. Available in different sizes and configurations, CNC milling machines enhance efficiency and productivity by operating continuously with minimal human intervention, enabling the production of intricate and accurate components.