& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

A bill of materials (BOM) is a comprehensive list of raw materials, components, and parts needed to manufacture a product. It serves as a blueprint for the production process, detailing every item needed to assemble the final product. A BOM includes part names, descriptions, quantities, and specifications. Manufacturers gain a clear understanding of what is needed for each stage of production and is necessary for inventory management, procurement, and production planning.

BOMs can vary in complexity and can range from simple lists for more basic products to intricate multi-level BOMs for complex assemblies. They're typically categorized into different types, such as single-level BOMs and multi-level BOMs. Single-level BOMs list components directly required for assembly, and multi-level BOMs break down sub-assemblies into further detail. By capturing, configuring, and managing all product data, BOMs play a critical role in maintaining product quality. They enhance communication among departments, support change management, and regulatory compliance.

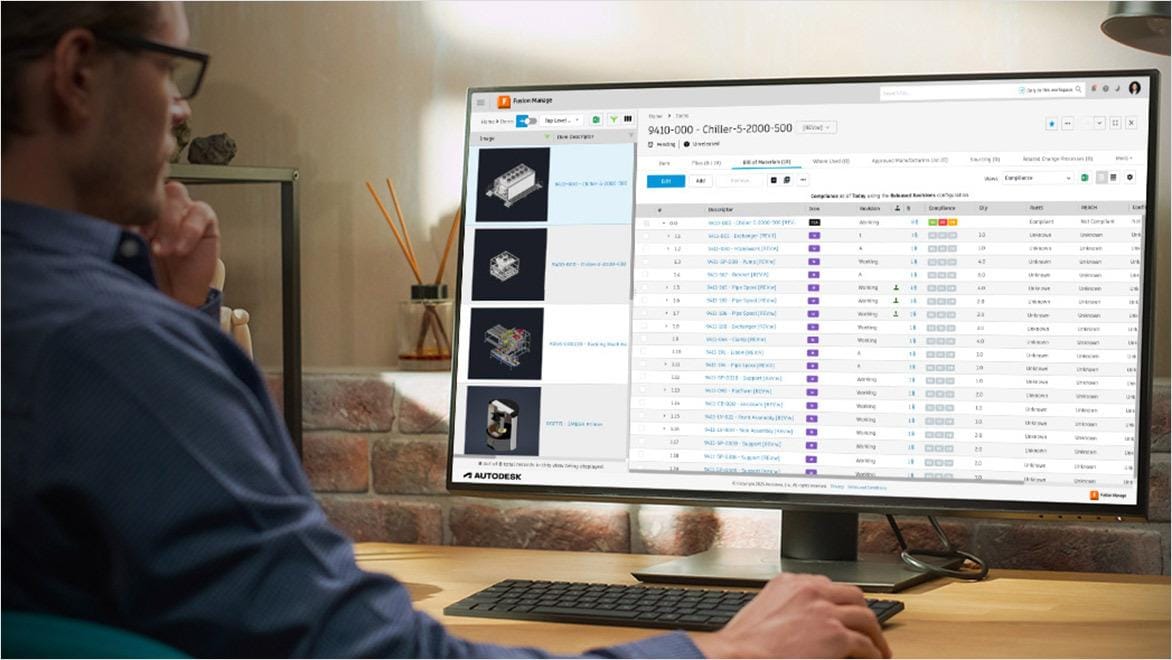

Real-time BOM management gives all departments access to the latest and most accurate information. This reduces the risk of errors, such as ordering incorrect parts or assembling products with outdated components, that often lead to costly production delays and known issues. By providing up-to-date BOM data, real-time management helps sync efforts across design, engineering, procurement, and manufacturing teams, enhancing overall coordination and efficiency.

Real-time BOM management supports rapid adaptation to changes in design, customer requirements, or market conditions. As modifications occur, they are instantly reflected in the BOM. This agility is a must in today's fast-paced manufacturing environment, where the ability to innovate and personalize products quickly can be a significant competitive advantage.

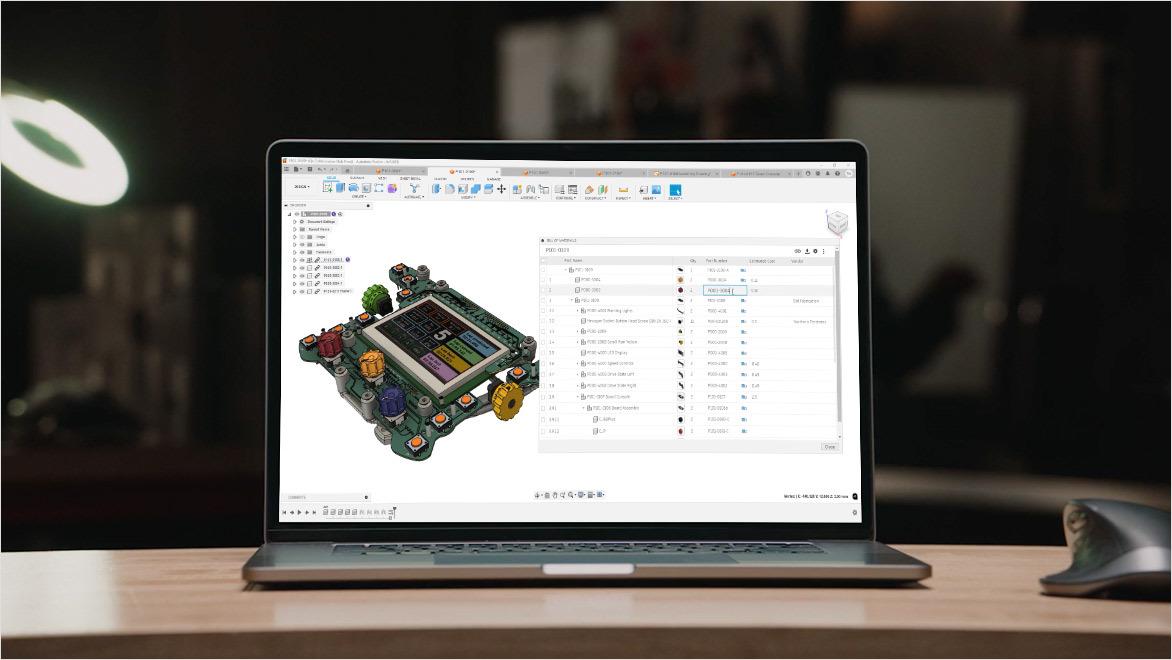

Bill of materials (BOM) software organizes the creation, management, and revision of BOMs within manufacturing processes. It automates the gathering of all necessary materials, components, and parts required for product assembly. BOM software also typically integrates with other enterprise systems such as ERP (Enterprise resource planning), and inventory management systems, for seamless communication and data exchange across departments.

Bill of materials software also allows manufacturers to easily update BOMs, track changes, and maintain consistency throughout the product lifecycle. By using BOM software, companies can better manage costs, optimize inventory, improve production planning, and maintain compliance with industry standards.

Implementing BOM software offers numerous benefits to organizations, including:

BOM management makes certain that all components and materials required for production are listed accurately, reducing the risk of errors and omissions during manufacturing.

By providing a detailed and organized list of materials, BOM management streamlines the production process. This leads to faster and more efficient operations.

BOM management helps track material costs and usage. This allows for better budgeting and cost management, leading to significant savings.

BOM management can be invaluable during troubleshooting and maintenance, providing a detailed reference for identifying and replacing defective parts.

BOM management helps organizations better manage inventory by knowing exactly what materials are needed and in what quantities, thus minimizing excess stock and shortages.

BOM management streamlines the production process by providing a detailed and organized list of materials. This leads to faster and more efficient operations.

By making sure that all necessary components are included and correctly specified, BOM management helps maintain high-quality standards in the final product.

BOM management accurately documents materials and components used in production to help make sure that products meet regulatory standards.

There are many kinds of BOMs, including purchasing BOMs, service BOMs, assembly BOMs, and others. The most familiar types of BOMs typically include

Engineering BOMs outline all items, parts, components, subassemblies, and subassemblies in the product. These are typically used by engineers and designers or use CAD or ECAD tools.

Manufacturing BOMs account for any parts that require processing or preparation before assembly. It's a go-to document for every part and assembly needed for a finished product.

The service BOM is a comprehensive inventory of all serviceable components required to maintain an asset during its operational lifecycle and is primarily used by mechanics, technicians, and other maintenance professionals.

During this time, BOMs were still primarily managed manually, however the introduction of typewriters and early computing machines helped streamline documentation.

Large manufacturing companies began using mainframe computers to manage inventory and production schedules, proving the framework for computerized BOM management.

Personal computers led to the development of early BOM management software.

ERP systems emerged, integrating BOM management with inventory control, production planning, and procurement.

BOM systems began to integrate with CAD software, allowing for the direct import of BOM data from design files.

PLM systems were introduced, providing a framework for managing product lifecycle data and here BOM became a core component of PLM.

The development of cloud-based BOM management systems has provided scalability, accessibility, and enhanced collaboration capabilities.

BOM software now includes features like real-time data synchronization, supplier integration, cost analysis, compliance tracking, and advanced reporting.

Artificial intelligence (AI) and machine learning (ML) are being integrated into BOM management systems to provide predictive analytics, automate routine tasks, and optimize inventory and production processes.

Blockchain technology is being evaluated for BOM management to ensure transparency, traceability, and security in the supply chain.

Here are some top industries that benefit from improved efficiency, reduced errors, and enhanced collaboration provided by effective BOM software solutions.

BOM helps consumer goods companies optimize production and inventory. It also improves collaboration between design, procurement, and manufacturing teams.

Bill of materials software helps automotive manufacturers manage complex assemblies and sub-assemblies. It also aids in maintaining compliance with industry standards and regulations.

The aerospace industry relies on BOM software to manage highly detailed and regulatory components. It also helps with traceability and compliance with strict quality standards.

Manufacturers use BOM for the efficient tracking of components and materials, and to streamline production processes and inventory management.

BOM systems help ensure accuracy and compliance with healthcare regulations and documentation for quality assurance.

BOM management software helps electronics manufacturers handle intricate designs and a multitude of detailed parts.

Bill of materials management plays a critical role in connecting product development data and processes, helping organizations maintain a digital thread. Here are benefits of BOM in the digital thread:

The digital thread offers a complete, interconnected view of product data throughout its lifecycle. By linking BOM information with design, manufacturing, and service data, it boosts traceability and promotes visibility at every stage of the product development process.

Integrating BOM management with the digital thread lets design, engineering, procurement, manufacturing, and service teams collaborate seamlessly, keeping everyone on the same page with the latest information.

The digital thread keeps BOM data accurate and up-to-date across all systems. This reduces entry errors, speeds up decision-making and improves operational efficiency, driving faster time-to-market and lowering costs.

BOM stands for bill of materials. It's a comprehensive list of all components, materials, parts, and sub-assemblies required to manufacture a product. BOMs also include the quantity, description, and specifications of each item.

A bill of materials helps make sure that all necessary materials and components are available for production. BOMs also helps with cost estimation, support inventory management, and provide a clear blueprint for assembling the final product.

BOM software improves efficiency by automating the creation and updating of BOMs. They provides real-time access to information, accurate documentation, and boosts collaboration among different departments. Bill of materials software also helps in tracking costs and managing changes seamlessly.

BOM software helps with cost management by calculating the cost of materials and components, monitoring expenses, and providing insights into cost-saving opportunities. It ensures that budgets are adhered to and helps in optimizing resource allocation.

BOM management involves the processes and systems used to create, maintain, and update the BOM throughout the product lifecycle. It maintains accuracy, version control, and effective communication of changes to all stakeholders.