& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

With the global supply landscape becoming increasingly more competitive and complex, effective inventory management is crucial.

Autodesk Fusion Operations's Inventory Management capabilities, offer a comprehensive solution, addressing the common challenges faced by businesses in managing their inventory.

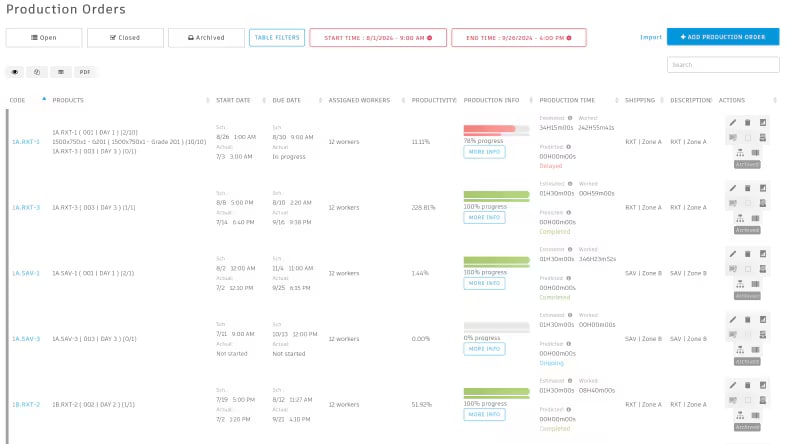

Schedule and manage teams, machines, and materials.

Get real-time production visibility powered by devices on the shop floor. Track and analyze your entire production flow.

Track maintenance operations and easily plan future actions with fully integrated maintenance management.

Overstocking ties up capital, increases storage costs, and risks inventory obsolescence. Autodesk Fusion Operations helps you with your inventory control and minimizes these risks, ensuring optimal stock levels that align with demand forecasts. This not only frees up capital but also enhances operational agility, preventing the costly pitfalls of excess inventory.

Labor-intensive methods slow down operations, hinder real-time data accuracy, and can significantly impact decision-making. Autodesk Fusion Operations streamlines these processes, boosting efficiency and enhancing accuracy, providing a solid foundation for informed inventory decisions.

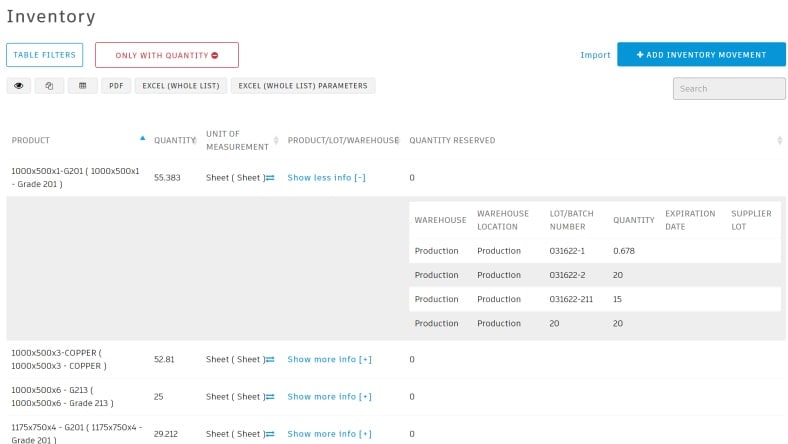

Finding specific products becomes a time-consuming task, disrupting workflow and productivity, and leading to inaccuracies in inventory levels. Efficient stock organization is essential to streamline operations, minimize search time, and maintain accurate inventory records, ensuring smooth and reliable business processes.

Scalability in inventory management is key for growing businesses, ensuring you can handle increasing volumes and complexity, supporting expansion while maintaining efficiency. This adaptability is vital for integrating new products and markets seamlessly, fostering sustainable business growth.

Productivity increase year over year, reported by ReChaco, a division of Chacos.

Less rework year over year, reported by ReChaco, a division of Chacos.

Minimize the risk of running out of materials with real-time inventory counts that update based on production records.

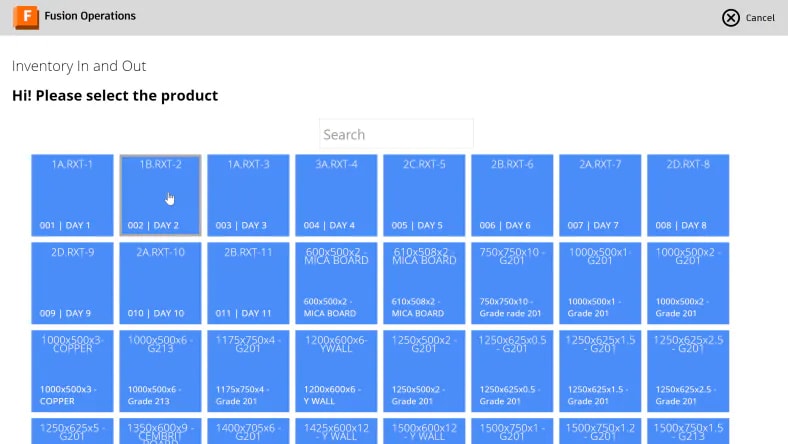

Create sales orders to base production orders off of to help ensure real-time synchronization between sales and production activities.

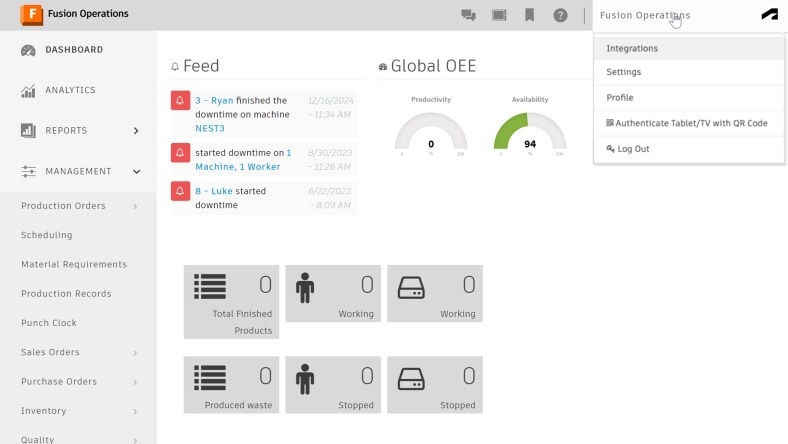

Customize integrations to third party applications using the Application Programming Interface, API.

Simplify recording of "stock out" (Shipping) and "stock in" (Receiving) movements to help refine sales order management.

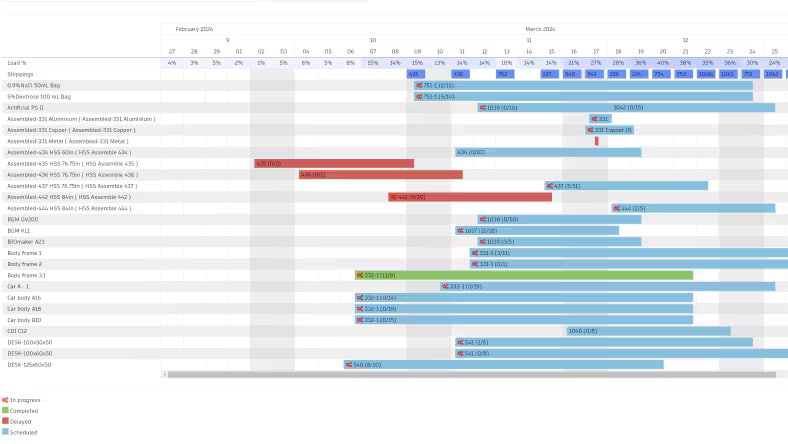

Manage production floor schedules for workers, machines, production jobs, and planned maintenance for improved flexibility when planning jobs.

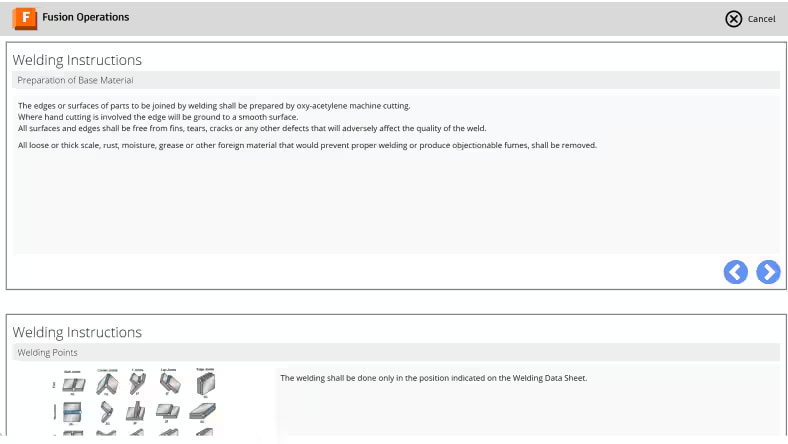

Empower workers to quickly access work instructions, including checklists and supplemental files such as part drawings.

Start effectively planning, managing, tracking and analyzing your manufacturing shop floor production with Autodesk Fusion Operations.

A Manufacturing Execution System (MES) is a software solution to automate and digitize manufacturing processes. Manage, monitor, and track the transformation of raw materials into finished products in real-time. Gain insight into manufacturing operations to see how to improve performance, lower costs and increase production efficiency.

Autodesk Fusion Operations brings together MES and ERP capabilities, consolidating the number of tools used, streamlining your workflow to require fewer tools, and enabling communication of relevant information back and forth.

Autodesk Fusion Operations is a multi-capable tool, used by manufacturing engineers, production managers, quality managers, fulfilment, and shop floor fabricators.