& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

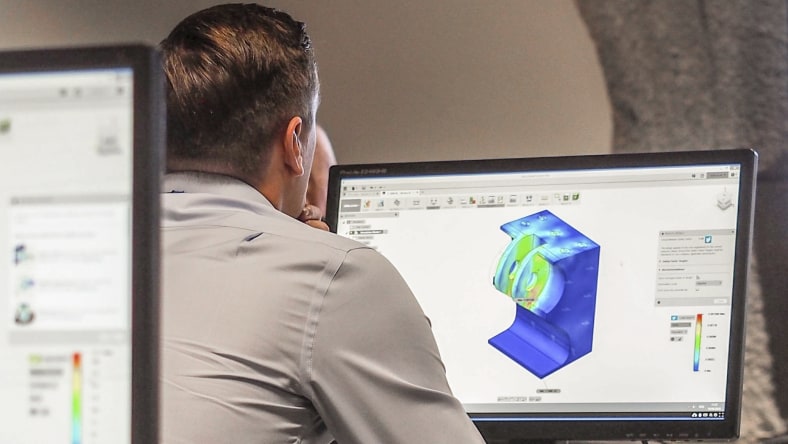

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Free access for educators at qualified educational institutions.

Free for students and educators at qualified educational institutions.

Free for school IT administrators at qualified educational institutions.

Option one

Sign up by choosing the product and plan you need, and providing a school-issued email address for verification.

Option two

Check your school-provided email inbox for an invitation from Autodesk. Or try signing in with your school-provided email address.

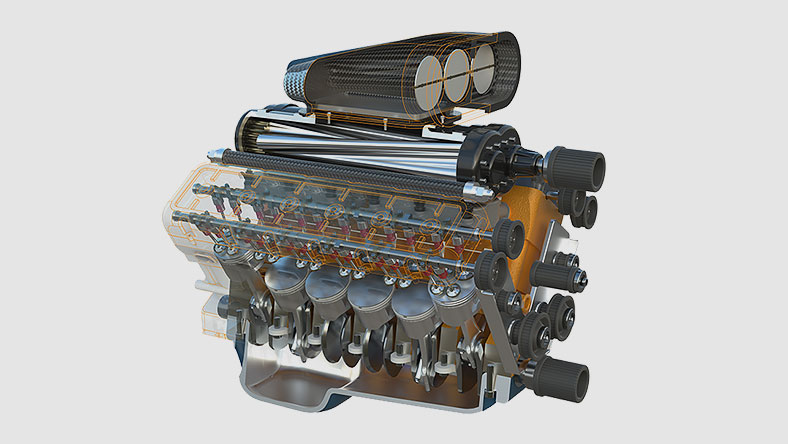

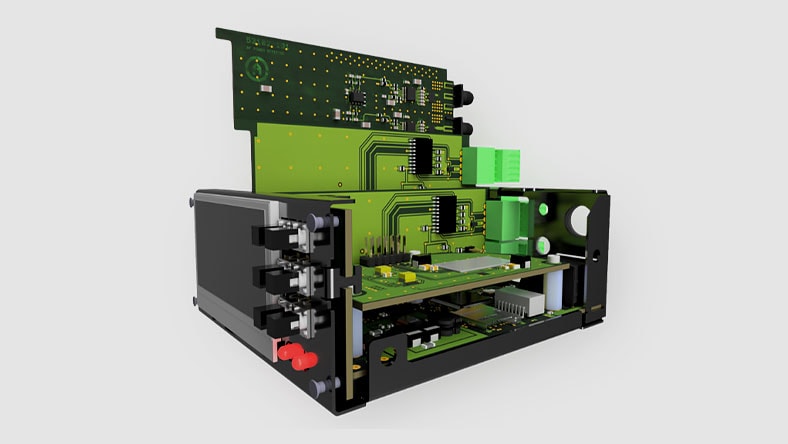

Autodesk Fusion is a professional, full-scale integrated 3D modeling cloud-based CAD/CAM/CAE/PCB platform that lets you design and make anything.

Fusion is the tool of choice for industry professionals across manufacturing, machining, engineering, and industrial design. Leading commercial customers use Fusion to make the new possible.

Fusion is free for eligible educators and students. Available on Mac, PC, and Chromebook.

Centralize and manage students' assignments and projects. Students can share a link to their design, and you can view it, add markup, slice the model, and comment directly in your browser, on any device.

Fusion's collaboration features make it easier for students to work on the same project – when a new version of a dataset is uploaded, it is immediately available to everyone collaborating on the project.

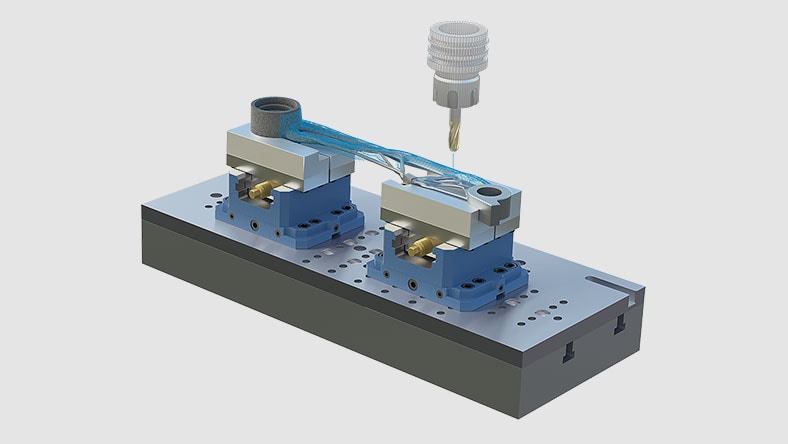

Get students to produce high-quality CNC machined parts, and additively manufacture builds with a wide range of integrated CNC and 3D printers ready to simulate, test and prototype designs.

Ensure that students are making adequate progress and submitting original work with file version history.

Take models from other CAD programs, even in the original format, and use them directly in Autodesk Fusion to collaborate with your students.

All data files are securely encrypted in the cloud, meaning project files follow the student. For low-connectivity settings, offline mode kicks in when internet goes out.

New enhancements are coming to Autodesk Fusion that will streamline the design experience. This update aims to help all users work more confidently with parts and assemblies, while enabling improved group collaboration and large assembly performance.

You can enable the Intent driven design preview today to try it yourself.

Autodesk Fusion enables you to explore many iterations quickly with easy-to-use CAD software.

Produce high-quality CNC machined parts, and additively manufacture builds using FFF or PBF for metal 3D printing.

Gain all the advantages of a full-featured schematic capture, electronics design, and mechanical CAD with Autodesk Fusion.

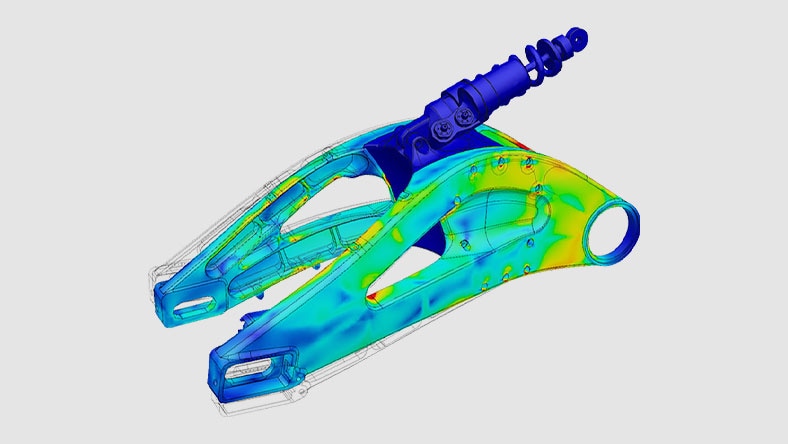

Test your designs to ensure they survive real world conditions. Simulate digitally and reduce prototyping costs.

Explore many manufacturing-ready outcomes meeting your design specifications through generative design.

Use integrated cloud collaboration tools to bring teams together and manage product data.

Just in time for the new school year, we’re excited to introduce Fusion Classrooms, a powerful new feature that makes student onboarding faster and easier than ever before.

Step 1

Get started today and enhance your workflow by learning about our new classroom feature that automates and accelerates the process of setting up your classes in Fusion.

Step 2

Setting up a classroom is now easier than ever. Follow this step-by-step guide to successfully set up your first Fusion Classroom.

Step 3

Dive deeper and discover how you can use Fusion Classrooms to supercharge your teaching, provide meaningful feedback, and enhance the student experience.

Educators Nate Baker and Michael Mavor at Clover Park Technical College share how Fusion has helped them double their students' projects and learning. With CAD and CAM in one software platform, Fusion has accelerated student success as they embark on new careers for Industry 4.0.

Master the basic concepts of Fusion with self-paced lessons. Each path includes videos, step-by-step tutorials, and downloadable 3D models.

Explore teaching and learning resources for Fusion, designed and organized for easy implementation in your classroom curriculum.

Help students gain confidence and stand out by earning certifications in CAD, CAM, design-to-manufacture workflows, and generative design.

Fusion Fundamentals is a free 12-hour course aimed at training educators how to use, teach, and implement Fusion into their classroom.

Yes, Autodesk offers a free version of Autodesk software, including Autodesk Fusion, with full features and functionality for qualifying students and educators.

The Autodesk Education plan offers one-year free access to Autodesk software and services for qualifying students and educators. Educational access is renewable annually as long as you are eligible.

If you are eligible, you can select Autodesk Fusion on the Education Products page to start the verification process. Once you are successfully verified, you can access all software available through the Education Community, and access is renewable anually as long as you are eligible.

Autodesk offers one-year free access to Autodesk software, including Autodesk Fusion, and services for our Individual or Classroom plans. Educational access is renewable annually as long as you are eligible.

Yes, Autodesk offers eligible university students one-year free access to Autodesk software, including Autodesk Fusion, and services.

If you already have an Autodesk account, sign in first to get the best experience. If you're new to Autodesk, signing up for the Education plan will create your Autodesk account. After you sign in, select Autodesk Fusion on the Education Products Page. Next, select the subscription plan that matches your role.

Software and cloud-based services subject to an Educational license or subscription may be used by eligible users solely for Educational Purposes and shall not be used for commercial, professional or any other for-profit purposes.

Autodesk offers qualified educational institutions access to the same design software used by the world’s leading professionals to help students build the skills and knowledge needed for a successful career.

If you no longer qualify for the Autodesk Fusion educational license, you can sign up for a free 30-day trial.

Institutions now have greater control to distribute Autodesk software to up to 3,000 students and educators with fewer verification steps. You can also enable the optional Autodesk SSO to make product access even easier.

Free Autodesk software and/or cloud-based services are subject to acceptance of and compliance with the terms and conditions of the terms of use and/or other terms that accompany such software or cloud-based services. Software and cloud-based services subject to an Educational license or subscription may be used by eligible users solely for Educational Purposes and shall not be used for commercial, professional or any other for-profit purposes.