& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Part deburring is the process of removing burrs, which are small, often sharp, protrusions or rough edges that occur on metal, plastic, or other workpieces during manufacturing processes, such as machining, milling, drilling, or cutting. Burrs are created during machining processes due to the nature of material removal, where the cutting action of tools generates excess material at the edges of the workpiece. The formation of burrs can be attributed to several factors and are an inevitable by-product of machining processes.

Burrs can affect the performance, safety, and appearance of a part. Deburring is an essential step to make sure that components meet quality standards and function correctly. It's critical for maintaining the proper fit, function, and safety of manufactured parts. The choice of deburring method depends on factors such as part material, geometry, production volume, and required finish quality. Implementing effective methods is essential so that the final parts meet quality and performance standards.

As the cutting tool shears material from the workpiece, the material undergoes plastic deformation. When the cutting force is applied, the material can deform and flow. This leads to the formation of burrs at the edges where the tool exits the material.

When the cutting tool exits the material, it often leaves behind a small protrusion or rough edge because the material is not supported. As a result, the cutting action is not as controlled as when the tool is fully engaged. This phenomenon is common in operations like drilling, milling, and turning.

A worn or dull cutting tool can create more significant burrs because it does not cut the material cleanly. Instead, it tends to drag and tear the material, leading to rough and jagged edges.

Incorrect cutting parameters, such as feed rate, cutting speed, and depth of cut, can contribute to burr formation. For example, too high a feed rate or too low a cutting speed can increase the tendency for burrs to form.

The material being machined plays a crucial role in burr formation. Softer materials, like aluminum or certain plastics, are more prone to burr formation due to their tendency to deform easily. Harder materials can also produce burrs, but they may be smaller and more brittle.

Different machining methods create different types of burrs. For instance, drilling often produces burrs around the hole edges, while milling can produce burrs along the cut edges and corners. Each method has unique characteristics that influence how and where burrs form.

During machining, chips are formed as the material is removed. The way these chips break and evacuate from the cutting zone affects burr formation. Continuous chips can smear material along the edges, creating burrs, while segmented chips can reduce this effect.

The heat generated during machining can soften the material around the cutting zone, making it more susceptible to deformation and burr formation. Proper cooling and lubrication can help minimize thermal effects and reduce burr formation.

Burrs can create sharp edges that pose a risk of cuts and injuries to workers handling the machined parts. Removing burrs creates a safer working environment.

Burrs can interfere with the proper fit and function of parts, leading to assembly issues or mechanical malfunction. Deburring ensures that parts fit together correctly and function as intended.

Burrs can negatively impact the surface finish and overall quality of a machined part. Removing them improves the aesthetic and functional quality of the product.

Burrs can create stress concentrations that may lead to premature wear, fatigue, or failure of parts. Deburring helps to enhance the durability and longevity of machined components.

Burrs can alter the dimensions and tolerances of machined parts. Removing them ensures that parts meet the required specifications and maintain high precision.

Burrs can create crevices that trap contaminants and moisture, leading to corrosion and degradation of the part. Deburring helps to maintain the integrity and corrosion resistance of the material.

Sharp edges are acute angles where surfaces meet on a part. These areas concentrate stress, complicate manufacturing, and pose safety concerns. By incorporating a deburring process, the strength of the part increases, fit with other components improves, and the risk of cuts and injuries during handling reduces. Overall, the quality of the part is enhanced with a smoother and more aesthetic surface finish.

It is common practice to manually remove burrs during a post-processing step using hand tools such as files, scrapers, or abrasive stones. This method often results in inconsistencies, leading to parts that are either overprocessed or underprocessed, and is highly labor-intensive. By integrating deburring into the machining process, manufacturers can achieve higher quality and more consistent parts while concurrently reducing overall labor and production costs.

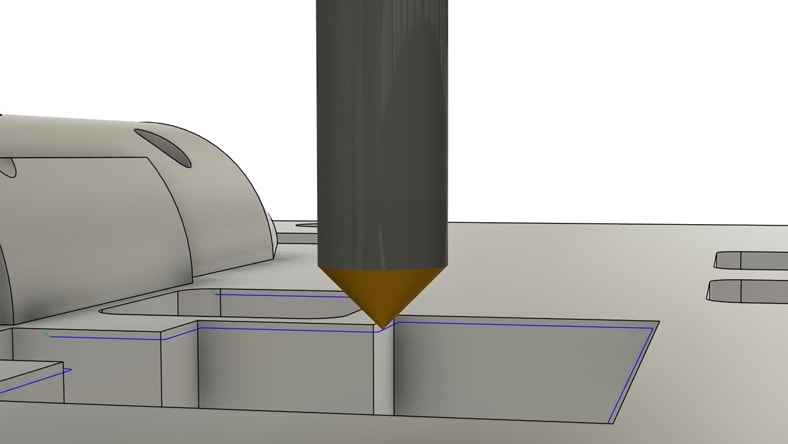

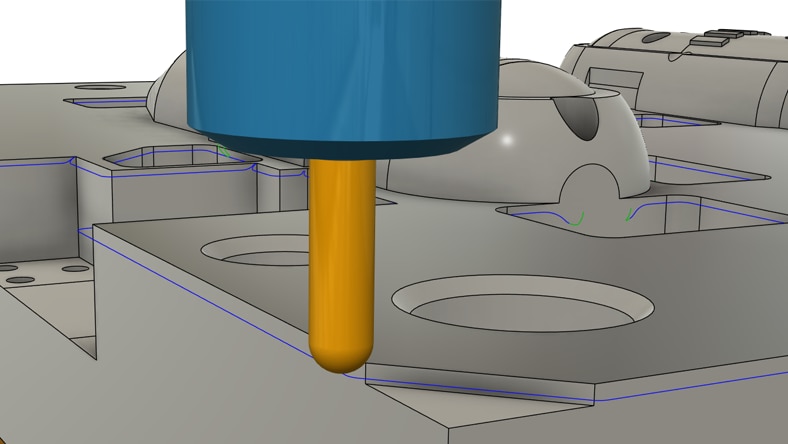

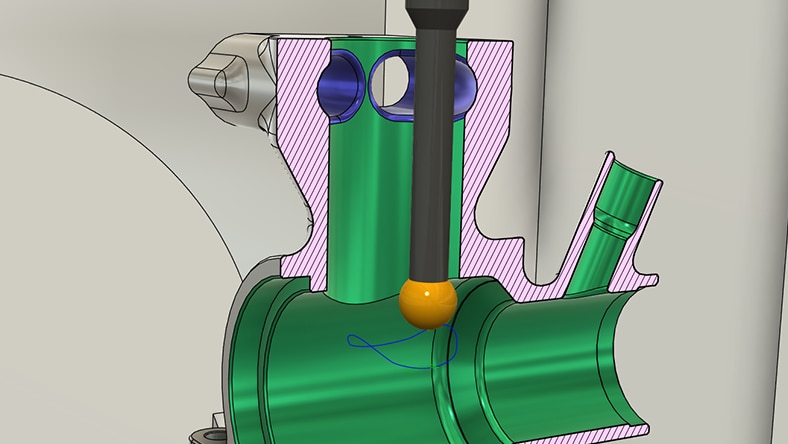

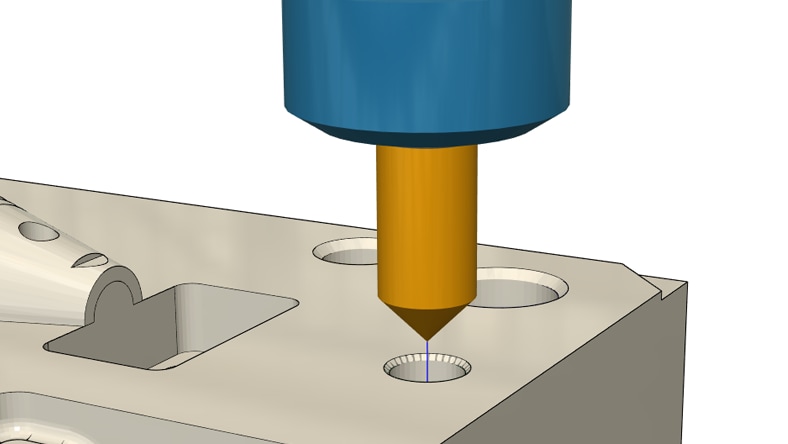

The deburr toolpath in Autodesk Fusion for Manufacturing revolutionizes the industry with automated burr removal from machined parts. Users can select from various cutting tools, such as chamfer, ball, spherical endmills, and spot drills, to create precise deburr toolpaths. This feature automatically detects and processes external sharp edges, allowing users to specify a minimum edge angle or manually select edges for deburring. The generated toolpath can be customized with parameters for edge shape and corner handling, helping to acheive optimal results. The toolpath also supports multi-axis machining, facilitating 3-, 4-, or 5-axis machine motion controls to prevent collisions and errors. To enhance cutting smoothness, users can add loops for smoother motion and specify a point along the tool's flute to utilize the least-worn portion. This advanced deburring capability improves surface finish, reduces manual labor, enhances product performance, and increases overall efficiency in manufacturing processes.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Chamfer endmills have a V-shaped cutting edge that allows them to cut at an angle, creating a chamfer on the edge of the material. The cutting edge is typically angled at a specific degree.

A ball endmill has a hemispherical or spherical cutting end, which allows it to create smooth curves and contours on a workpiece.

Spherical endmills have a hemispherical or spherical cutting end with a reduced shank size. The rounded end makes them ideal for 3D contouring and complex surface machining.

Spot drills have a short and rigid design with a sharp point, typically with an included angle of 90 degrees or 120 degrees. This design ensures precise and accurate positioning of the initial hole.

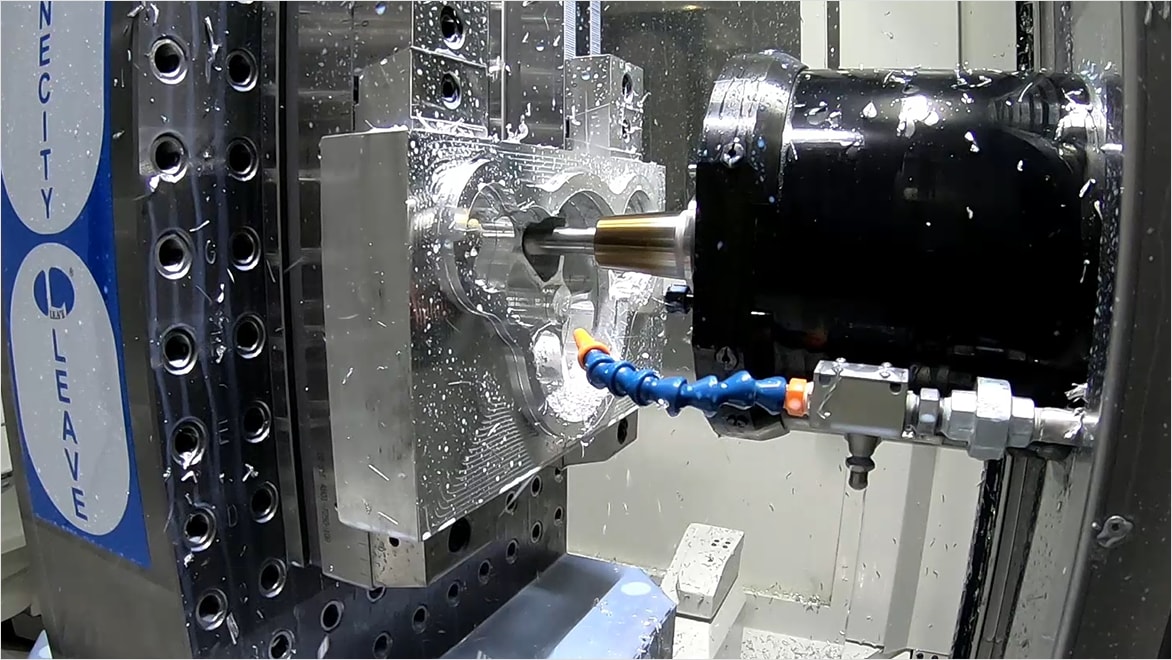

A 3-axis machining center is a CNC machine tool that moves along X, Y, and Z axes. It allows for the precise milling, drilling, and cutting of complex parts.

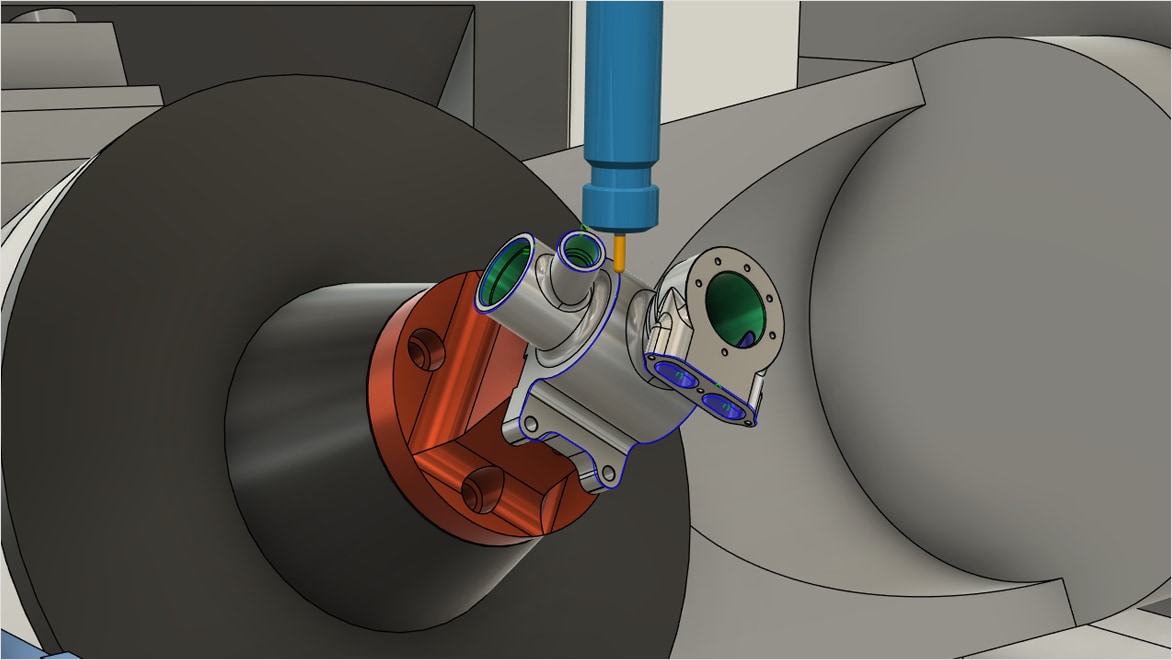

A multi-axis machining center is a CNC machine tool that moves along multiple axes, including rotation, allowing for complex and precise machining operations on intricate parts from various angles.

A turnmill is a CNC machine that combines turning and milling capabilities. This allows for both rotational and linear machining operations on a single setup, enhancing efficiency and precision.

Deburring machines remove unwanted burrs, sharp edges, and surface irregularities from machined parts to enhance their quality and functionality. These machines use various techniques, such as mechanical, thermal, or chemical processes, to achieve smoothness and precision. Mechanical deburring machines employ abrasive brushes, sanding belts, or grinding wheels to physically smooth the workpiece's surface, often in an automated manner to handle large volumes efficiently and consistently. Additionally, vibratory finishing machines use a combination of abrasive media, water, and vibratory motion to uniformly deburr parts with intricate geometries by gently tumbling them until the burrs are removed.

Thermal deburring machines use a controlled gas explosion to generate high-energy heat that instantly burns away burrs from the workpiece, making them highly effective for internal and hard-to-reach areas. Chemical deburring, also known as electrochemical deburring, involves immersing the workpiece in a chemical solution that selectively dissolves the burrs without affecting the base material. This precise method is ideal for delicate or complex parts. Overall, deburring machines are crucial in manufacturing, making sure that parts meet stringent quality standards, improving performance, and extending their lifespan.

The purpose of deburring is to remove unwanted burrs, sharp edges, and surface irregularities from manufactured parts, enhancing their quality, safety, and functionality. By eliminating these imperfections, deburring prevents injuries to workers and reduces the risk of damage to other components during assembly or operation. It ensures that parts fit together properly, operate smoothly, and perform as intended, while also increasing their durability by reducing stress concentrations that could lead to premature wear or failure. Deburring also improves the aesthetic appearance of parts and helps maintain tight tolerances and precise dimensions, making it a crucial step in achieving high-quality, reliable products.

Burrs are identified through various inspection methods to detect unwanted protrusions, sharp edges, and surface irregularities on machined parts. Common methods include visual inspection, where trained inspectors examine parts under good lighting, and tactile inspection to feel for roughness. Automated Optical Inspection (AOI) machines equipped with cameras and image processing software offer high accuracy for large volumes. Surface profilometry measures surface roughness to detect irregularities, while quality control gauges check dimensions and edges for compliance. Non-destructive testing techniques, such as ultrasonic, eddy current, or X-ray inspection, are also used for detecting burrs in complex or internal areas.