& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

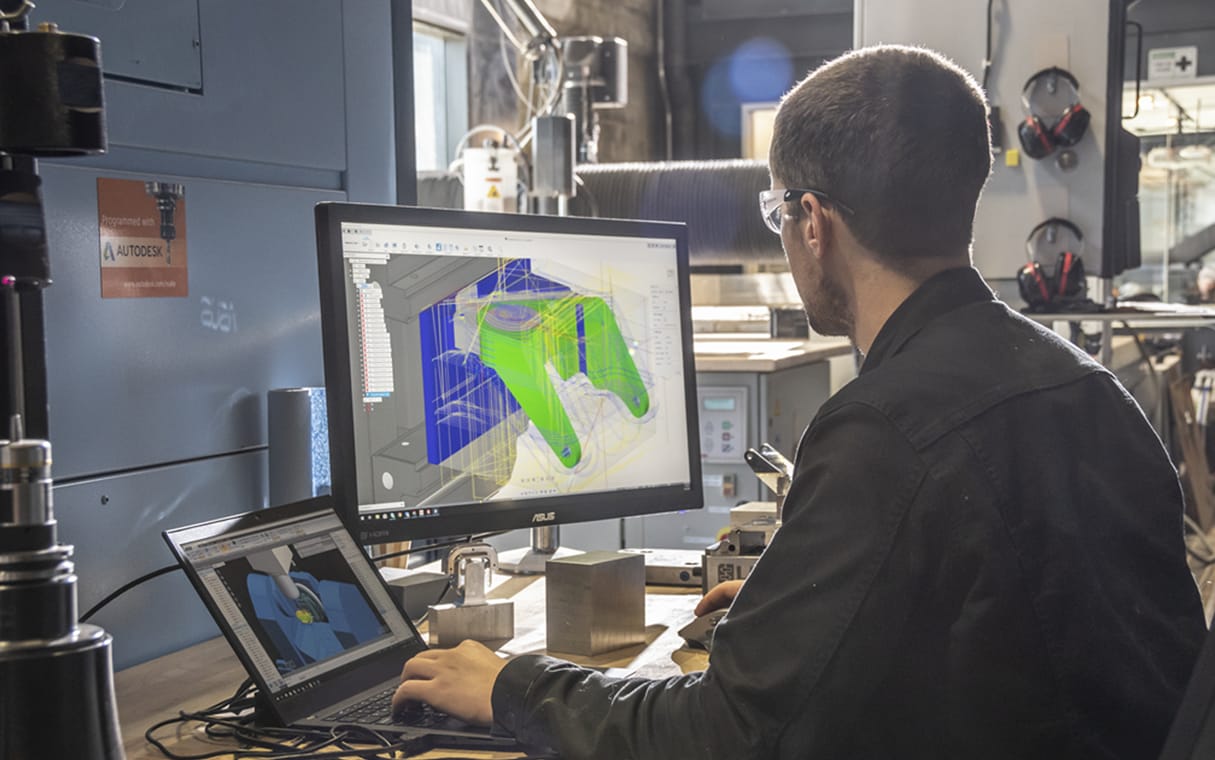

Professional CAD/CAM tools built on Inventor and AutoCAD

AI in CAD refers to the integration of artificial intelligence technologies into CAD software to improve the design process. This integration leads to more intelligent and automated design functions, such as generative design, which enables designers to specify requirements and constraints and receive optimized design options generated by AI. AI in CAD also features automated error detection, predictive modeling, and enhanced simulation capabilities, all of which greatly enhance efficiency, accuracy, and innovation in design and engineering workflows.

CAD AI is incredibly important in manufacturing because it streamlines the design and production processes, making them more efficient and accurate. It helps identify mistakes early, reducing the need for costly fixes later on. By automating repetitive tasks, it speeds up the entire workflow, allowing products to reach the market faster. This technology also enhances collaboration and decision-making through data-driven insights. Overall, CAD AI improves productivity, cuts costs, and enables the creation of better, more advanced products.

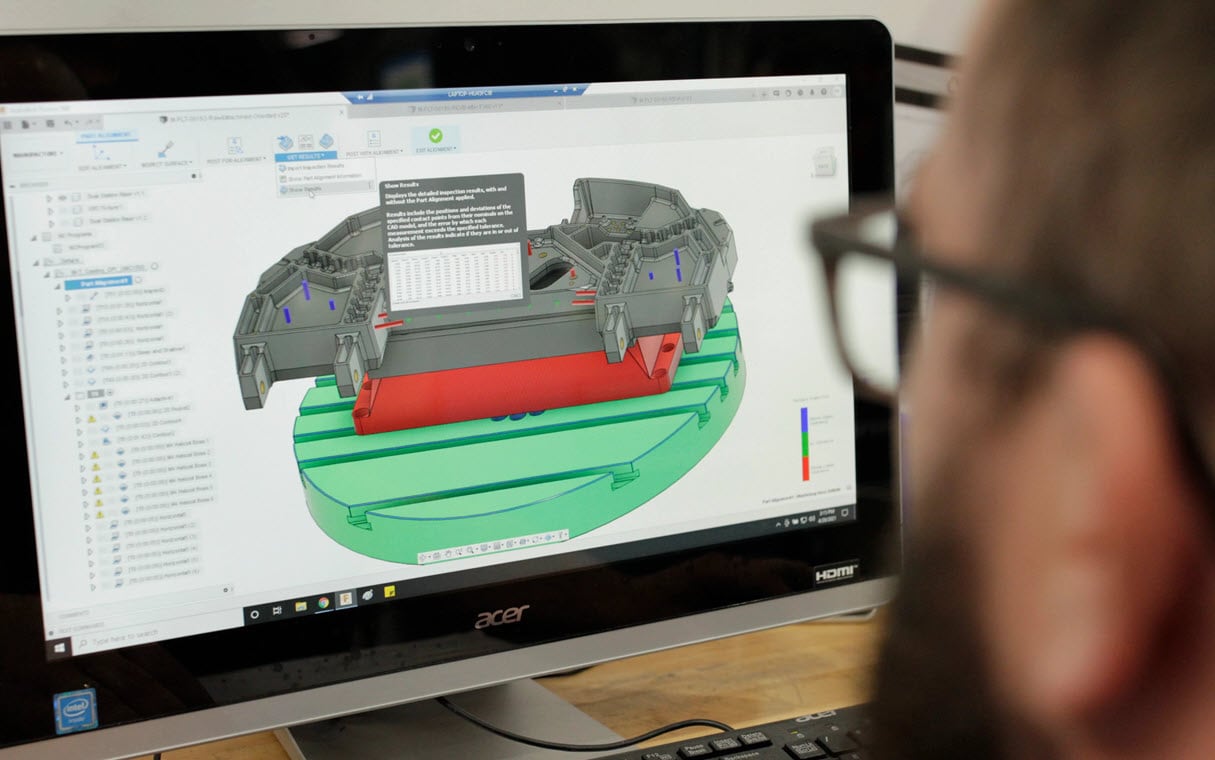

AI-powered CAD tools automate routine tasks like dimensioning and error detection, reducing manual work and speeding up design workflows.

AI detects design errors in real-time and suggests optimizations, reducing costly revisions and ensuring compliance with industry standards.

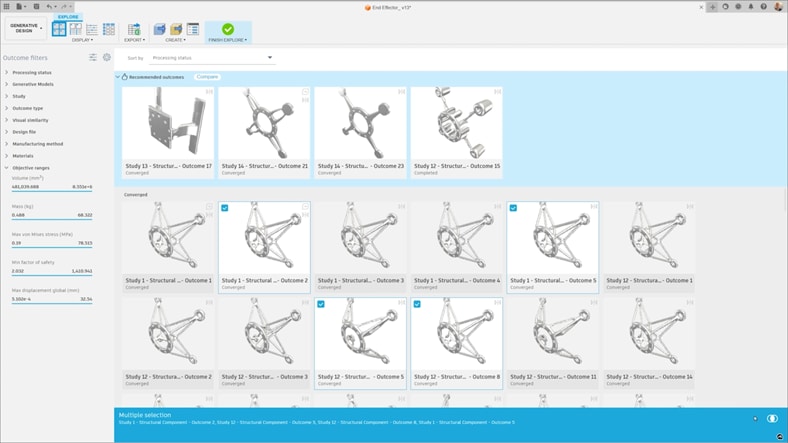

AI-driven generative design creates optimized alternatives, speeding iterations and enabling more innovative, efficient solutions.

AI-integrated CAD platforms enable seamless collaboration with real-time data and insights, improving communication and accelerating decisions.

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

Autodesk Fusion for Design brings together the essential features of Autodesk Fusion along with advanced tools from the Fusion Design, Simulation, and Manage Extensions—all at a lower price than buying them separately. With it, you get access to AI CAD tools that are smart and automated, making your work easier and more efficient. Plus, you can manage design changes at any stage with pre-built workflows, and check how well your designs will perform and be manufactured using integrated simulation tools.

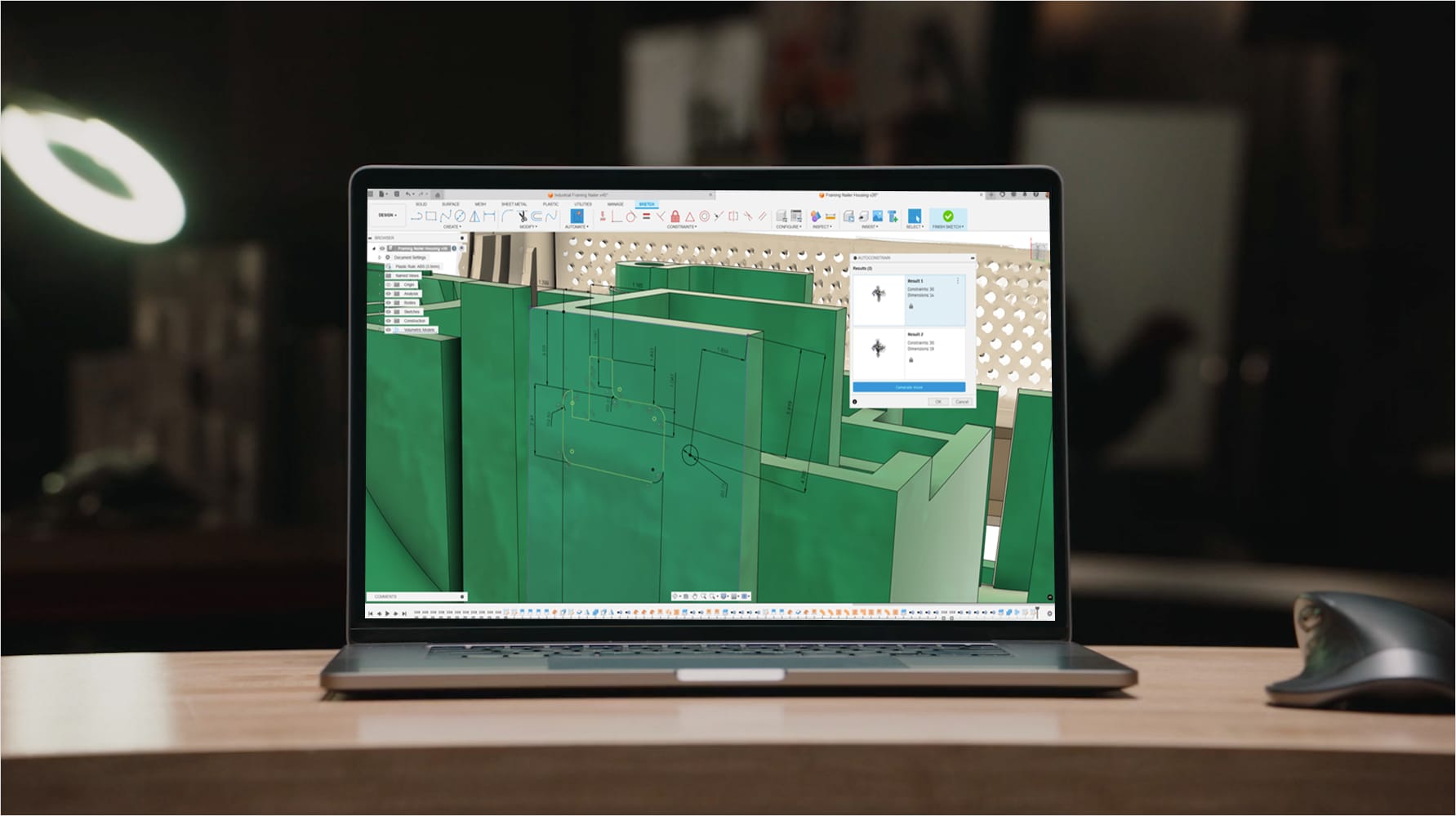

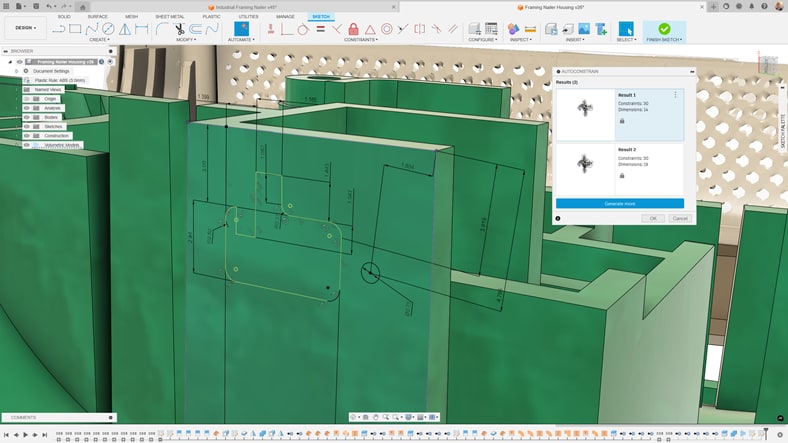

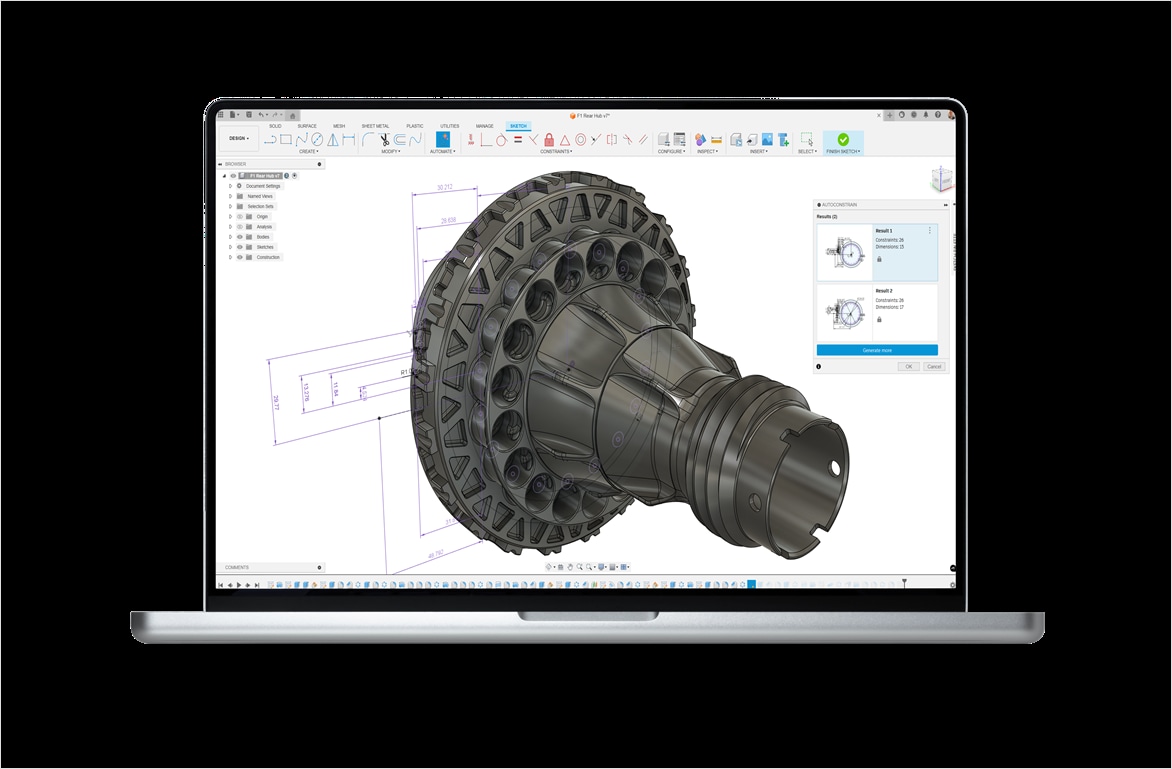

AutoConstrain uses artificial intelligence to streamline the definition of sketch geometry, making the process quicker and more straightforward than ever before.

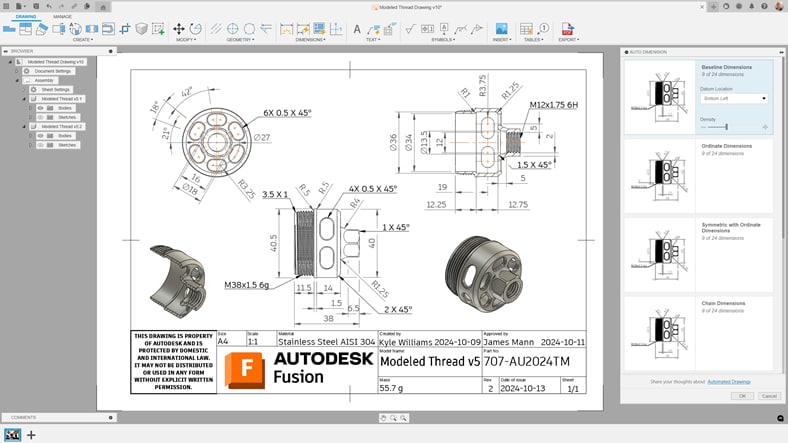

Fusion's AI-powered automated drawings streamline 2D drawing creation from 3D models, reducing manual input and errors.

Fusion's generative design tools give manufacturers and designers the ability to explore a vast range of design alternatives, enabling them to make more informed decisions and produce better outcomes.

Managing and designing intricate circuits in complex electronic systems offers significant challenges, requiring advanced design tools to ensure seamless integration of millions or billions of transistors. EDA tools must offer robust simulation, verification, and optimization capabilities to meet performance, power, and reliability requirements of modern electronics.

Making sure a design functions correctly and meets all specifications is a resource-intensive challenge in EDA. As designs grow more complex, traditional verification techniques may fall short. Advanced methodologies such as formal verification, hardware emulation, and AI-driven automation are often needed to enhance efficiency.

EDA tools must be able to scale effectively to handle larger datasets and more complex simulations without affecting speed or accuracy. Optimizing algorithms, leveraging high-performance computing resources, and ensuring efficient data processing are necessities to achieving scalability and high performance.

The concept of using computers for design and drafting began in the 1960s. Early CAD systems were developmed primarily for automating repetitive tasks and improving drafting efficiency. The 1970s brought the beginnings of AI research in CAD, focusing primarily on expert systems and rule-based approaches to assist with design decisions. Techniques such as knowledged-based systems started being applied to CAD for talks like automated reasoning, problem-solving, and design optimization in the 1980s.

In the 1990s, increased computational power made CAD systems more sophisticated, incorporating AI algorithms for optimization and simulation to enhance design efficiency and accuracy. In the 2000s, the emergence of machine learning and data mining techniques enabled CAD systems to learn from extensive design data, leading to advancements in predictive analysis and generative design.In the 1990s, increased computational power made CAD systems more sophisticated, incorporating AI algorithms for optimization and simulation to enhance design efficiency and accuracy. In the 2000s, the emergence of machine learning and data mining techniques enabled CAD systems to learn from extensive design data, leading to advancements in predictive analysis and generative design.

In the 2010s, AI became increasingly prevalent in CAD due to advancements in deep learning and big data analytics. Generative design, where AI algorithms generate optimized design alternatives based on specified constraints, gained significant popularity.AI also enhanced collaboration and integration across various engineering and design tools. Moving into the 2020s, AI in CAD has continued to evolve with the integration of more advanced machine learning techniques, natural language processing, and computer vision. These advancements have resulted in more intuitive and intelligent design tools, facilitating real-time collaboration, automated design validation, and improved design quality.

AI-driven CAD systems will make design work more efficient and creative by automating repetitive tasks, optimizing processes, and offering smart design suggestions. With AI-powered generative design, designers can quickly explore a wide range of design options while considering various constraints and requirements. Machine learning will boost the accuracy of simulations and predictive modeling, leading to better performance and easier manufacturing. Plus, AI will make CAD tools more user-friendly with features like voice and gesture recognition. Ultimately, AI in CAD will lead to smarter, faster, and more innovative design solutions, changing the way we create and develop products.

Connected data from design to manufacturing to production unlocks the opportunity to achieve significant, AI-driven productivity gains. By moving beyond repetitive, non-value-added, and time-consuming tasks, you can focus on what truly matters to your business: driving innovation.

Generative design AI in Autodesk Fusion, enables rapid exploration of multiple optimized design solutions. Read on to learn how this can benefit your design and manufacturing processes.

Learn about the advantages of AI for product design, explore applications across industries, and how to address ethical considerations.

Yes, there is AI for CAD. Autodesk Fusion incorporates AI-driven features such as generative design, which generates optimized design alternatives based on specified constraints, and predictive modeling, which forecasts design performance under various conditions. It also automates repetitive tasks, enhances simulation and analysis capabilities, and facilitates real-time collaboration. These AI features in Fusion significantly improve productivity, enhance design quality, and streamline the design and manufacturing process.

While AI brings significant advancements to the CAD industry, human designers will still play a crucial role. Creativity, problem-solving, and decision-making are areas where human expertise is indispensable. AI tools are likely to be seen as valuable assistants that augment the capabilities of traditional CAD rather than outright replacements.

Yes, Autodesk Fusion incorporates AI and machine learning features to enhance the design and engineering process. Some of these AI-driven capabilities include Sketch AutoConstrain, Automated Drawings, and Generative Design.

Some challenges associated with implementing AI in CAD include the need for significant computational resources, the complexity of integrating AI with existing workflows, the requirement for high-quality data for training AI models, and the potential learning curve for users to adapt to new AI-powered tools.

The benefits of using AI in CAD include increased productivity, reduced design time, enhanced creativity, improved design accuracy, better collaboration, and the ability to handle complex design challenges more effectively.

Machine learning contributes to AI in CAD by analyzing large datasets to identify patterns, make predictions, optimize designs, and continuously improve the performance and capabilities of CAD software based on user interactions and design outcomes.

AI improves CAD software by automating complex tasks, providing predictive modeling, enabling generative design, enhancing simulation and validation processes, and facilitating real-time collaboration and integration with other tools.

Generative design is an AI-driven process where algorithms generate optimized design alternatives based on specified constraints and requirements, allowing designers to explore a wide range of design possibilities.