& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Reduction in engineering time

Reduction in prototyping costs

Reduction in part weight

In custom automotive design, precision, passion, and performance are essential. Crafting components, recreating classic parts, or pushing speed and aerodynamics involves complex challenges. To meet demand, you need tools that match your speed and precision.

Autodesk Fusion offers an integrated, enterprise-grade platform with tools for smarter, faster work. From reverse engineering a classic fender to designing weight-optimized suspension arms or collaborating on race car parts, Fusion enhances innovation and efficiency in automotive fabrication.

Trickfactory Customs is a premier custom-car and fabrication shop specializing in full builds, from metal shaping to design. They blend hand-craftsmanship with advanced digital workflows, using 3D scanning and Autodesk Fusion for precise custom component design and fabrication.

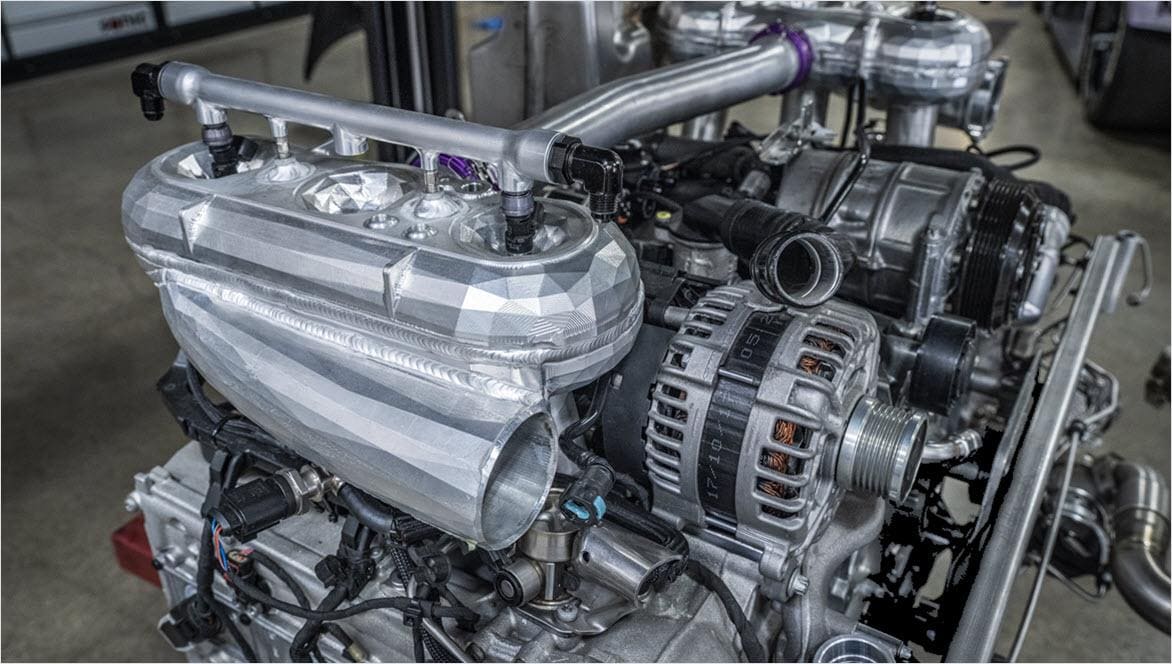

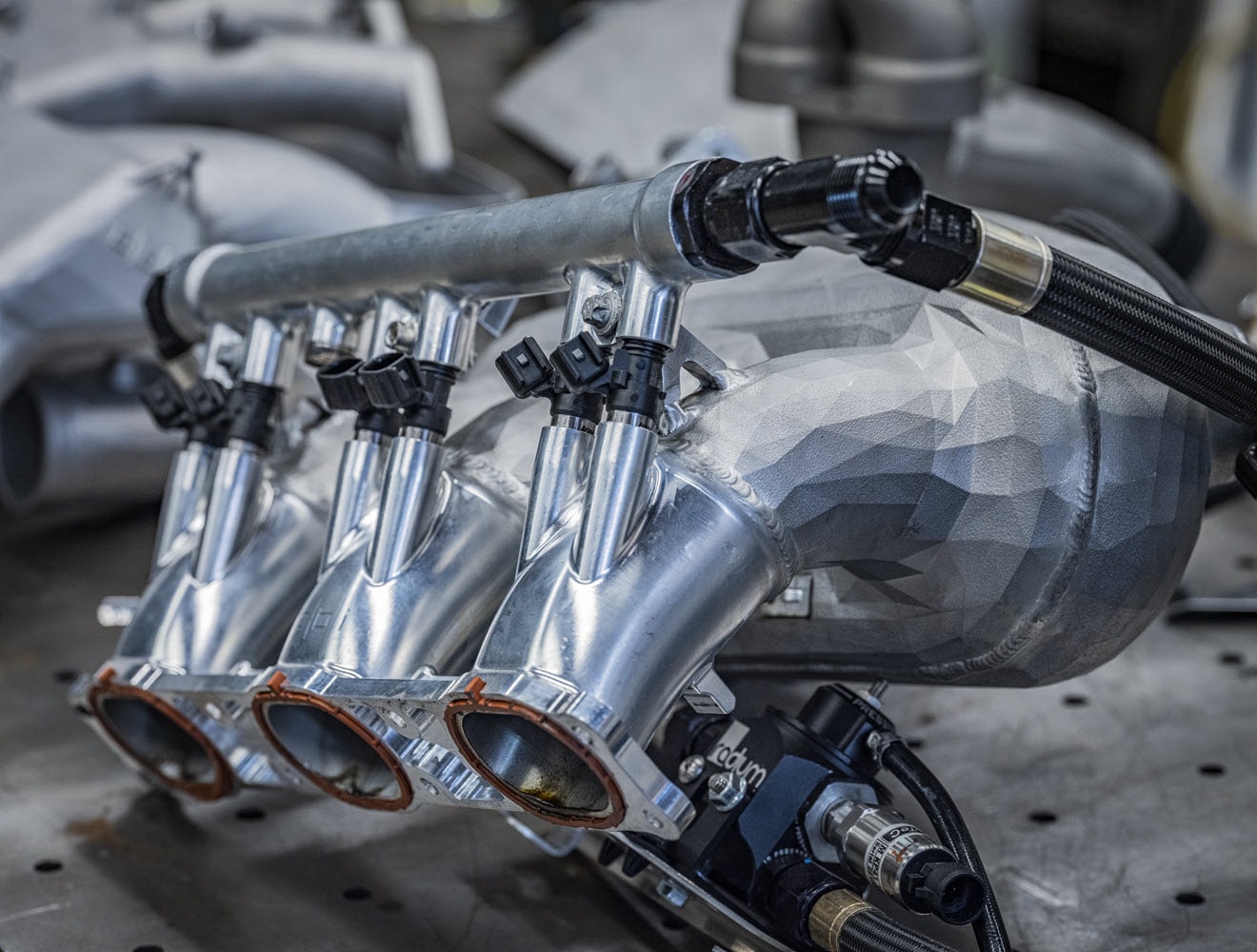

Rotary engine builder Rob Dahm uses Autodesk Fusion for his high-power automotive creations. Fusion's integrated CAD/CAM tools allow him to go from sketching and designing precision components to simulating, refining, and machining custom parts, helping him rapidly prototype complex, 1-of-1 designs.

Tadeu from Forza Racing is on a mission to build the fastest time-attack Mazda Miata in the world. From using freeform tools to design a fastback to fabricating an entire aero package for the car, Tadeu is able to jump back into improving his car immediately after testing it on the track.

Josiah Fallaise is a Formula Drift racer, builder, and founder of FDF Raceshop. He designs and fabricates his own race-ready components using Autodesk Fusion to conceptualize, model, and validate everything from bespoke suspension to chassis brackets for his car and FDF's high-end product line.

Robin Shute is an engineer and four-time Pikes Peak International Hill Climb champion. He uses Autodesk Fusion to model radical aerodynamics and apply generative design for ultra-light structural parts, bringing OEM-level engineering power to his one-person, record-breaking team.

High Performance Academy (HPA) provides top-tier online training for automotive enthusiasts and professionals. Their modular video courses teach the principles of modern car design, manufacturing, and performance, ensuring students learn to tune vehicles the right way.

Fellten is making a significant impact in the automotive industry by converting classic gas-powered cars into electric vehicles. Fellten retrofits old MINI Coopers, Porsches, and Land Rovers, preserving the vehicle's original style while reducing noise and pollution with an electric engine.

As a top machinist, Garrett Wade's feed is a showcase of precision-machined metal automotive performance parts. Each component is executed with expert rigor, resulting in surfaces that celebrate metal and geometry that elevates the functional into the sculptural.

Time is money—accelerating workflow from design to manufacturing means more projects and faster delivery. Integrated CAD, CAM, PDM, and automated tools streamline production and reduce errors.

Custom and restoration projects often lack OEM CAD files. Scan-to-CAD workflows, mesh-to-solid conversion, and advanced tools enable quick, accurate reverse engineering and performance-driven design.

Fewer physical prototypes save time and costs while speeding up validation. Generative design, simulation, and additive integration create lighter, stronger parts without compromising strength.

Autodesk partners with industry leaders in manufacturing to develop collaborative technology integrations that streamline workflows to get you working faster, increase your manufacturing throughput, and maximize profit potential.

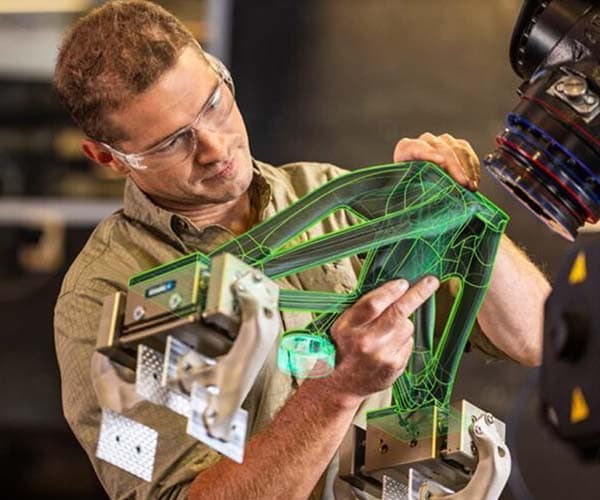

Easily convert physical parts into accurate digital models without OEM data using Fusion's scan-to-CAD workflow. Import 3D scans, automate mesh-to-solid conversion, and reconstruct complex shapes with T-Spline technology.

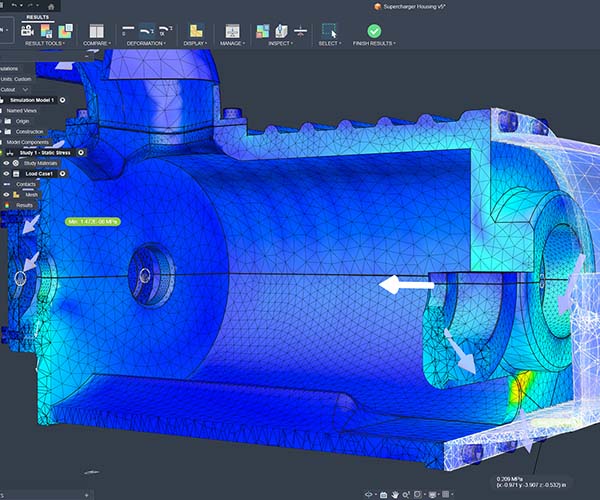

Cut development time and minimize physical testing using Fusion’s integrated simulation tools. Leverage AI-powered generative design for optimized parts, run comprehensive stress and thermal analyses, and seamlessly prepare models for additive and CNC manufacturing

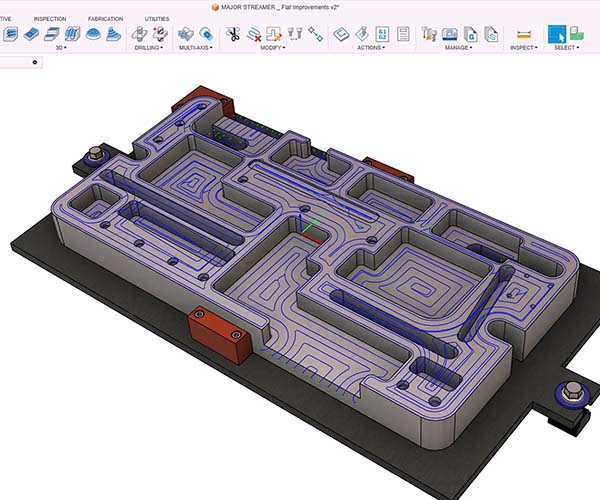

Unify your design and manufacturing processes with Fusion's seamless CAD/CAM integration. Generate toolpaths with a single click, directly export to CNC machines and 3D printers supporting multi-axis and hybrid machining, and speed up setup with automated fixture and stock preparation.

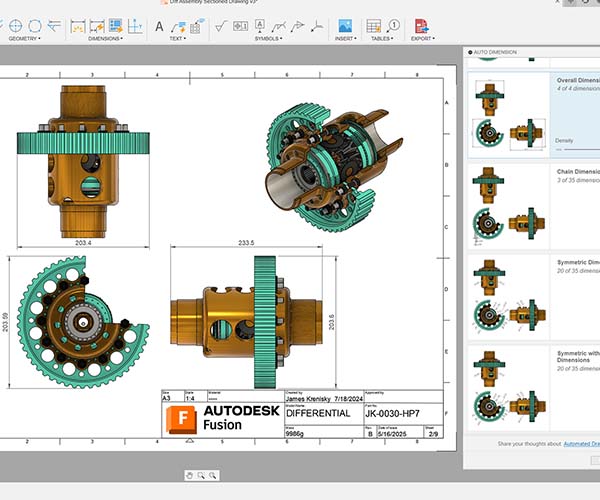

Ensure your designs meet regulatory and industry standards before manufacturing with built-in simulation and analysis tools. Access certified material libraries, perform structural and thermal validations, and maintain full documentation with integrated version control and audit trails. This approach lowers compliance risks, cuts testing costs, and accelerates your product’s time to market.

Effortlessly design complex, optimized components tailored for custom applications using Fusion’s advanced modeling tools. Utilize parametric controls for quick updates, leverage generative design to automatically create efficient structures, and sculpt intricate organic shapes with T-Spline surface modeling.