& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Manufacturing convergence is blurring industry lines. Specializing in one design field, like automotive, is obsolete as evolving software redefines capabilities. Designers and engineers seek more efficient ways to design and build, unconstrained by aging software solutions.

This convergence is already visible, such as architects using new methods like 3D printing with concrete for modular construction.

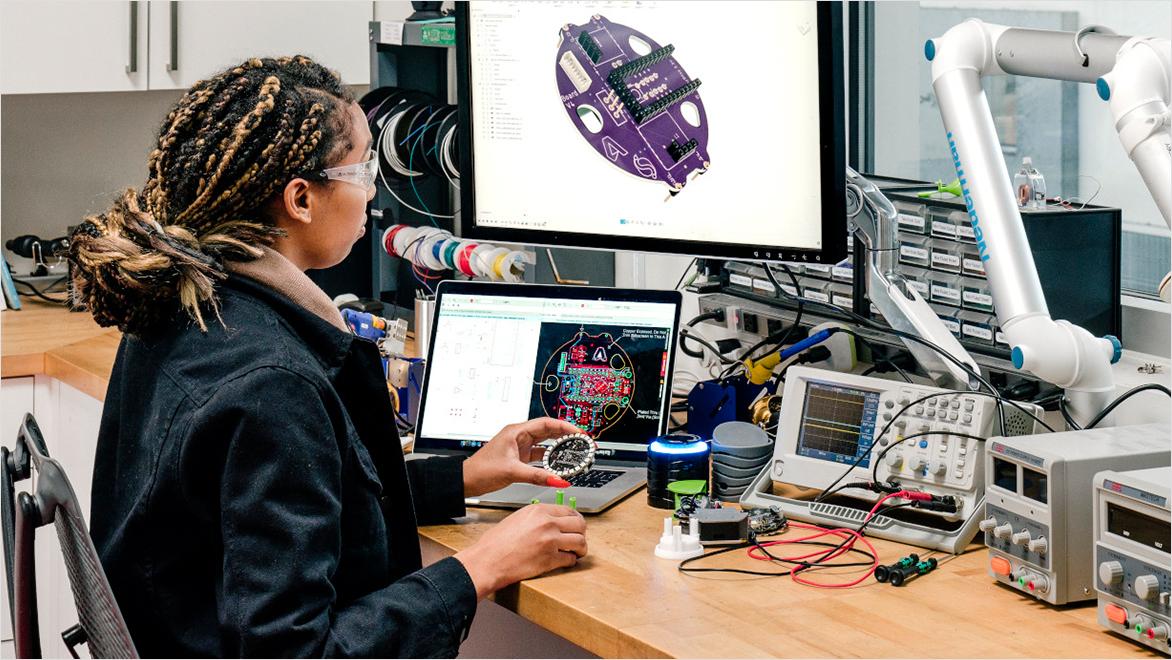

Autodesk Fusion accommodates all industries. Its tools allow critical prototyping—testing a design for form, function, fit, and durability. For example, an automotive designer can prototype an engine part and then immediately design a PCB for the dash display, all within Fusion.

ECAD is used to design and create electronic structures. Its counterpart, mechanical computer-aided design (MCAD), is used to design and develop mechanical systems. As we’ve seen, the automotive industry continues to implement more and more electronics and PCBs into their designs.

Autodesk Fusion enables seamless integration ECAD and MCAD. As products continue to become more lightweight and compact, plastic enclosures call for smaller electronic components.

When a plastic enclosure is modified, Autodesk Fusion will subsequently adjust parameters of the PCB within or related to that enclosure.

Autodesk Fusion enables going from sketch to a manufactured product faster and easier.

Customize your access to advanced tools and functionality with Autodesk Fusion extensions; flexible to meet your budget and timelines.

Gain access to complex design, machining, nesting, generative, simulation, additive manufacturing, and data management workflows.

Within the last decade alone, manufacturing processes and correlating software have changed.

Data convergence is when all data is stored in one location on the cloud for real-time access. Autodesk Fusion is built around data convergence as a cloud CAD platform.

Autodesk Fusion Manage has a library of pre-built workflows to help manage change orders, item numbering, bill of materials, and other data from the beginning to the end of the project. Part numbers are automatically assigned to each component.

Autodesk Fusion is a cloud CAD platform, which is one of the most desirable features in today’s work-from-anywhere business environment.

Cloud CAD is a term for cloud-based software solutions that operate in a local browser or through a web or mobile application via the Internet. Traditionally, CAD software had to be loaded on a localized computer.

Cloud CAD offers the same capabilities as traditional CAD software without being restricted to one desktop computer; especially beneficial for hybrid or remote work environments, where sharing information with a team through the cloud is preferred.