& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Factory simulation is the use of computer‑based models to represent, analyze, and optimize real‑world manufacturing systems. Instead of experimenting physically on the factory floor, teams use simulation tools to explore virtual versions of their production processes.

Factory simulation software automates this modeling, allowing users to visualize workflows, test what‑if scenarios, and predict how changes will impact throughput, resources, and overall performance. It provides a risk‑free environment to evaluate design decisions, identify bottlenecks, and optimize operations before making real‑world investments.

Autodesk FlexSim is a leading factory simulation software solution because it combines ease of use, high‑end 3D modeling, and powerful analytics in a single, intuitive platform. FlexSim is designed to help teams model, visualize, and optimize production systems before making real‑world changes.

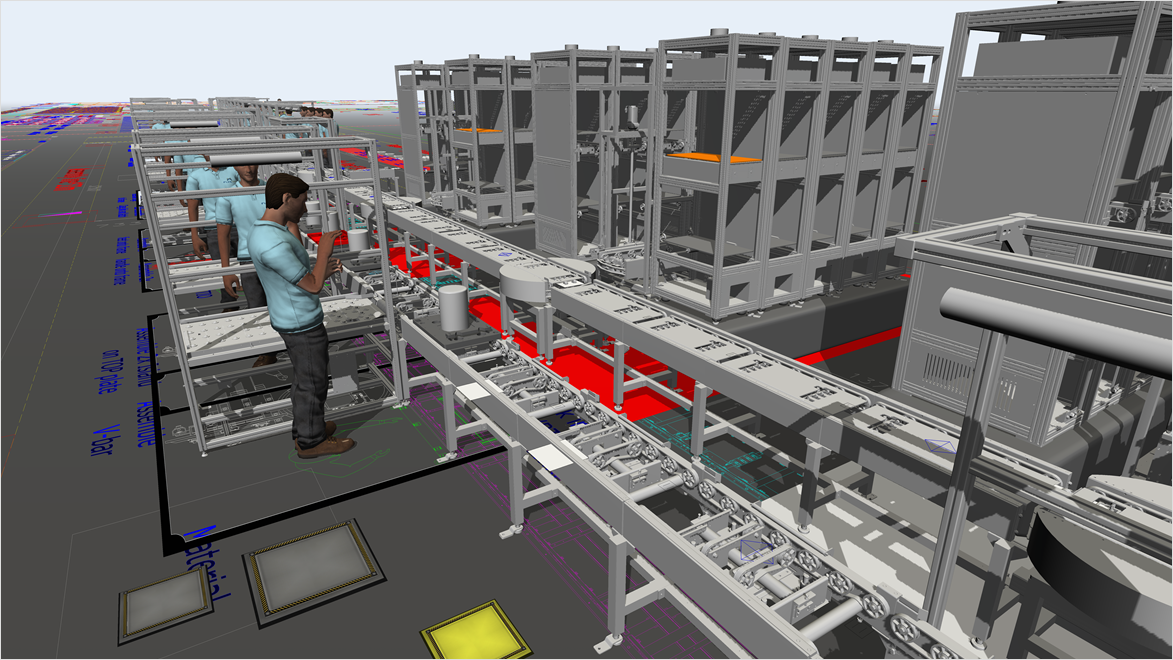

FlexSim provides a fast, accurate simulation engine wrapped in drag‑and‑drop controls, object libraries, and intuitive logic‑building tools. This makes it accessible, while still offering the depth to perform sophisticated analyses. Models are automatically built to scale and rendered in rich 3D visuals, making it easy to spot bottlenecks, inefficiencies, or layout issues at a glance.

Beyond visualization, FlexSim delivers robust statistical reporting and scenario experimentation, giving decision makers the data they need to validate assumptions and quantify the impact of proposed changes. Teams can run “what‑if” scenarios, compare system configurations, and make confident, evidence‑based decisions to optimize throughput, and reduce operational costs.

Factory simulation delivers the insights manufacturers need to improve performance. It helps teams predict outcomes, minimize risk, and visualize improvements long before implementing them in the real world.

Use evidence‑based simulation models to forecast how changes in equipment, staffing, or workflows will impact production before committing time or budget.

Run "what‑if" scenarios in a safe digital environment to identify bottlenecks, evaluate alternatives, and validate decisions without disrupting real‑world operations.

Use realistic 3D models and process visuals to clearly communicate system behavior, build stakeholder confidence, and create a shared understanding of the factory’s performance.

Explore the powerful tools that help you rapidly build realistic simulations, test ideas safely, and uncover the best path to optimized factory performance.

Build accurate simulations fast with drag‑and‑drop layout, a rich object library with pre‑built logic, and a code‑free logic environment that cuts model authoring time dramatically.

Ingest live or historical production data (rates, cycle times, downtime, orders) to keep models evidence‑based and aligned with real‑world performance.

Define stations, routings, buffers, shifts, and constraints with fine‑grained control to mirror actual factory behavior and policies.

Render layouts and flows in realistic 3D to spot bottlenecks and collisions quickly, and align stakeholders around a shared, visual source of truth.

Run side‑by‑side what‑if tests (layouts, staffing, batch sizes, AGV logic) and compare KPIs to select the highest‑impact option with confidence.

Track throughput, utilization, WIP, and wait times with exportable charts/tables that make data‑driven decisions fast and defensible.

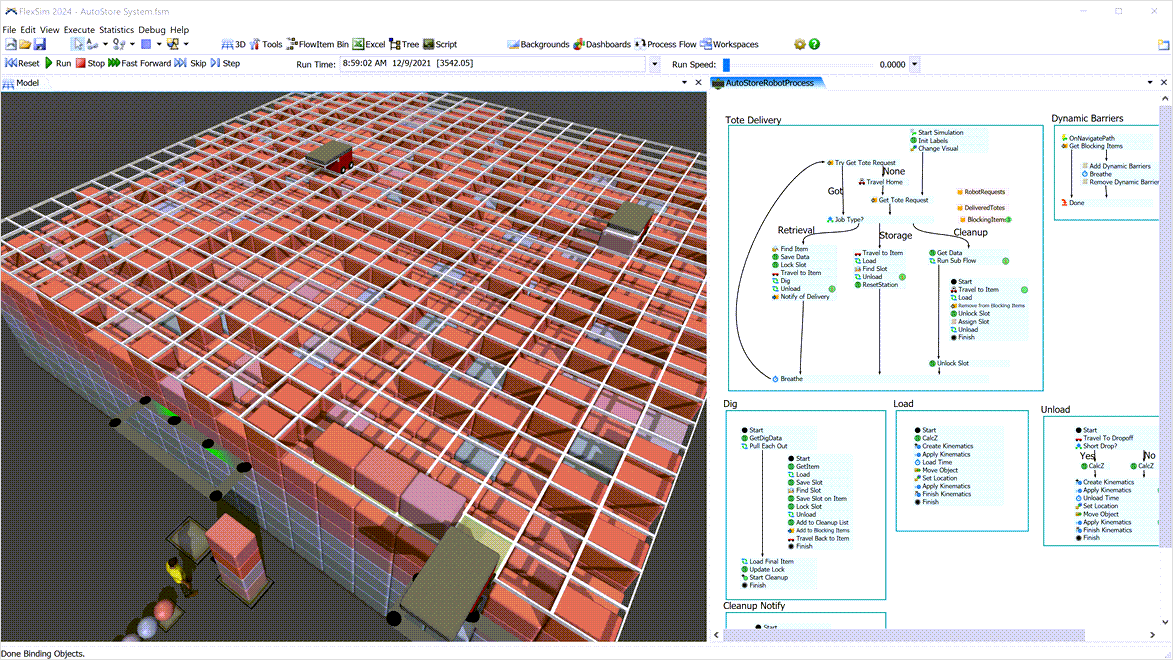

Autodesk FlexSim is 3D discrete‑event simulation (DES) software used to model and analyze how a factory operates over time. Using DES, FlexSim represents production as a sequence of events, rather than relying on averages or static calculations. Examples include parts arriving, machines starting or stopping, workers becoming available, or queues forming. Users build a to‑scale digital model of the factory with drag‑and‑drop objects (machines, conveyors, buffers, people), define process rules like processing times and routing, and then simulate how materials, equipment, and labor interact under real‑world constraints. This approach makes it possible to visualize bottlenecks and system behavior as it actually emerges from those events, not just how it looks on paper.

Once the model is running, FlexSim collects detailed performance data, including throughput, cycle time, utilization, and waiting time, and presents it through built‑in charts and dashboards. Teams can then use the Experimenter to run multiple “what‑if” scenarios, such as changing staffing levels, layouts, or machine reliability, and compare outcomes without disrupting live operations. FlexSim is often paired with Factory Design Utilities, linking accurate factory layouts to DES‑based operational simulation so manufacturers can test, optimize, and justify decisions before making physical changes on the shop floor.

How factory simulation powers smarter operations in every major sector.

Factory simulation software helps manufacturers optimize production lines, reduce bottlenecks, and validate layout changes before they hit the shop floor. It enables teams to test scenarios, improve throughput, and make data‑driven decisions with greater confidence.

Automotive companies use factory simulation software to streamline assembly operations, model complex workflows, and support the shift toward electric and autonomous vehicle production. It reduces costly trial‑and‑error by predicting performance and capacity outcomes upfront.

In aerospace and defense, factory simulation software models highly complex production environments, ensuring safety, precision, and efficiency. It supports planning, resource allocation, and scenario testing without disrupting mission‑critical operations.

Healthcare and pharmaceutical organizations use factory simulation software to improve production lines for medical devices, optimize lab and facility workflows, and model processes that must meet strict regulatory and quality requirements.

Advanced factory simulation tools boost efficiency, spark innovation, and strengthen competitiveness by helping manufacturers optimize processes, design better layouts, and stay agile.

Factory simulation software tools like Autodesk FlexSim help healthcare teams analyze and optimize patient‑focused processes, improving care quality, efficiency, and overall outcomes.

Explore how factory simulation and virtual reality enhance manufacturing by streamlining production workflows and improving operational efficiency. Learn the key advantages of using manufacturing simulation software.

Factory simulation is the use of a computer‑based, digital model to represent a real manufacturing system so teams can understand, analyze, and improve how it operates. It allows manufacturers to study materials, equipment, and people together in a virtual environment, reducing the need for costly or disruptive physical testing while supporting data‑driven decision‑making.

Most factory simulation tools use discrete‑event simulation (DES), which models production as a sequence of events, such as parts arriving, machines starting or stopping, or queues forming over time. By running the simulation and testing “what‑if” scenarios, teams can identify bottlenecks, compare alternatives, and predict how changes to layouts, staffing, or processes will impact throughput and efficiency before making real‑world changes.

Factory simulation software, like Autodesk FlexSim, is a type of computer software used to create a digital model of a real manufacturing facility so teams can understand, analyze, and improve how the factory operates before making physical changes. It represents machines, materials, people, and workflows together in a virtual environment, allowing manufacturers to study production behavior without disrupting live operations.

The top three benefits of factory simulation software include:

Factory simulation software, like Autodesk FlexSim, can help solve key problems in production and warehousing, including:

Factory simulation software is used most heavily in industries where complex operations, variability, and high capital risk make trial‑and‑error impractical, including:

Yes, Autodesk FlexSim is a factory simulation software solution. It's used to model, simulate, and optimize production, material flow, and logistics processes in factories and logistics centers. It enables users to build virtual factory models, run “what‑if” scenarios, and analyze throughput, capacity, and resource utilization before making real‑world changes.

The right factory simulation software should:

Learn more about Autodesk FlexSim for factory simulation.

Yes, you can download a free trial of Autodesk FlexSim here.