& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

people rely on coral reefs for food security

of all marine species live on coral reefs

of the world's coral reefs could be lost by 2050

Sources:

Motivated by a catastrophic coral bleaching event in her home country of Australia, Dr. Taryn Foster founded nature tech company, Coral Maker, to change the scale of coral restoration. After joining the Autodesk residency program in 2019, the Autodesk Technology Centers in Birmingham, UK and San Francisco, USA began supporting Coral Maker pro bono.

Using Autodesk’s Design and Make Platform, Coral Maker is innovating new technologies capable of scaling coral reef restoration, replacing what’s been lost and rehabilitating the world’s most biodiverse ecosystem.

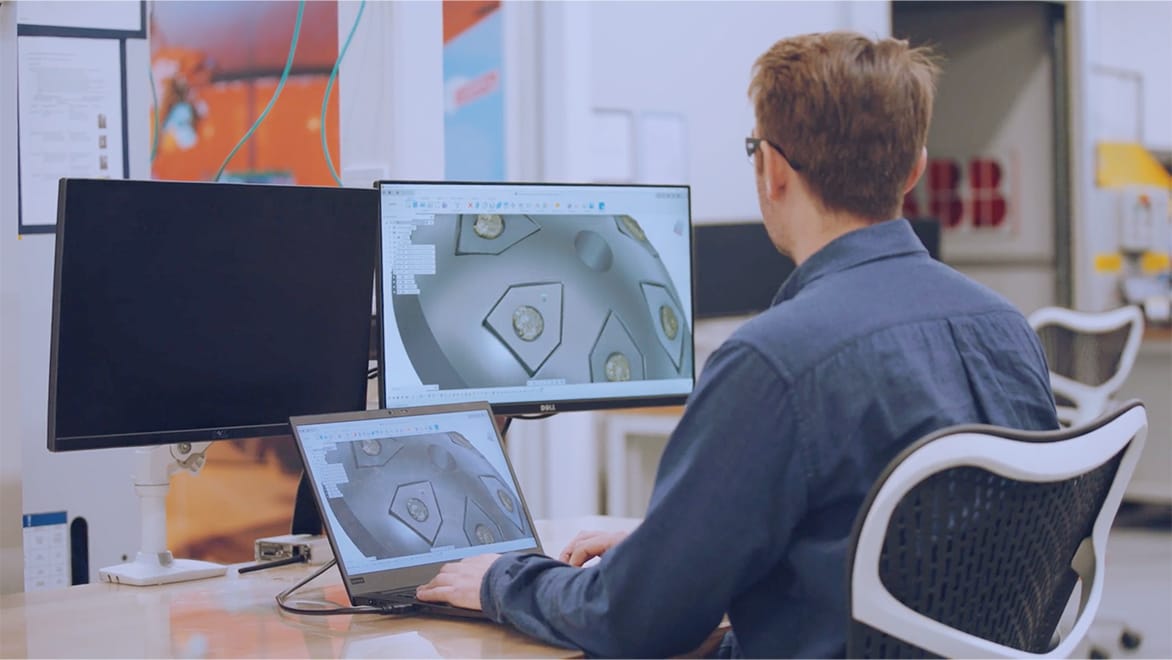

The Autodesk Technology Center in Birmingham, UK supports Coral Maker with design and engineering expertise, while manufacturing the coral skeleton mold castings on its CNC machines. Using Fusion 360, design data is centralized and updated in real-time to enable smooth collaboration across three time zones.

The Autodesk Technology Center in San Francisco is testing AI-powered robotics to automate the often tedious and manual seeding and propagation of corals, speeding up and reducing the cost of the process, leading to robots working collaboratively with people during large-scale restoration efforts.

Rewatch the live panel discussion with Coral Maker founder, Dr. Taryn Foster, and the Autodesk robotics team as they shared about their visionary work with robots and the future of coral reef restoration.