& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Digital manufacturing refers to the use of digital technologies to create, design, test, and produce products. It encompasses a wide range of processes, including computer-aided design (CAD), computer-aided manufacturing (CAM), 3D printing, and advanced robotics, to enhance production efficiency, reduce costs, and improve product quality. Digital manufacturing leverages data and interconnected systems to optimize manufacturing operations and product lifecycle management.

Digital manufacturing offers numerous benefits, revolutionizing traditional manufacturing processes.

Digital manufacturing streamlines processes, reduces waste, and optimizes resource utilization, leading to higher productivity and lower operational costs.

It allows for rapid adjustments in production lines, making it easier to switch between different products or customize products to meet specific customer demands.

With real-time monitoring and data analytics, digital manufacturing ensures higher quality and consistency in products by identifying defects and issues early in the production process.

By using digital tools such as simulation and virtual prototyping, manufacturers can design, test, and refine products faster, significantly reducing the time required to bring a product to market.

Digital manufacturing integrates various aspects of the supply chain, providing better visibility and control over inventory, logistics, and supplier performance, leading to a more responsive and resilient supply chain.

It promotes sustainable practices by optimizing resource use, reducing waste, and enabling the use of additive manufacturing techniques, which can lower the environmental impact compared to traditional subtractive manufacturing methods.

Digital manufacturing aims to create a smarter, more connected, and efficient production ecosystem that can rapidly adapt to changing market demands and technological advancements.

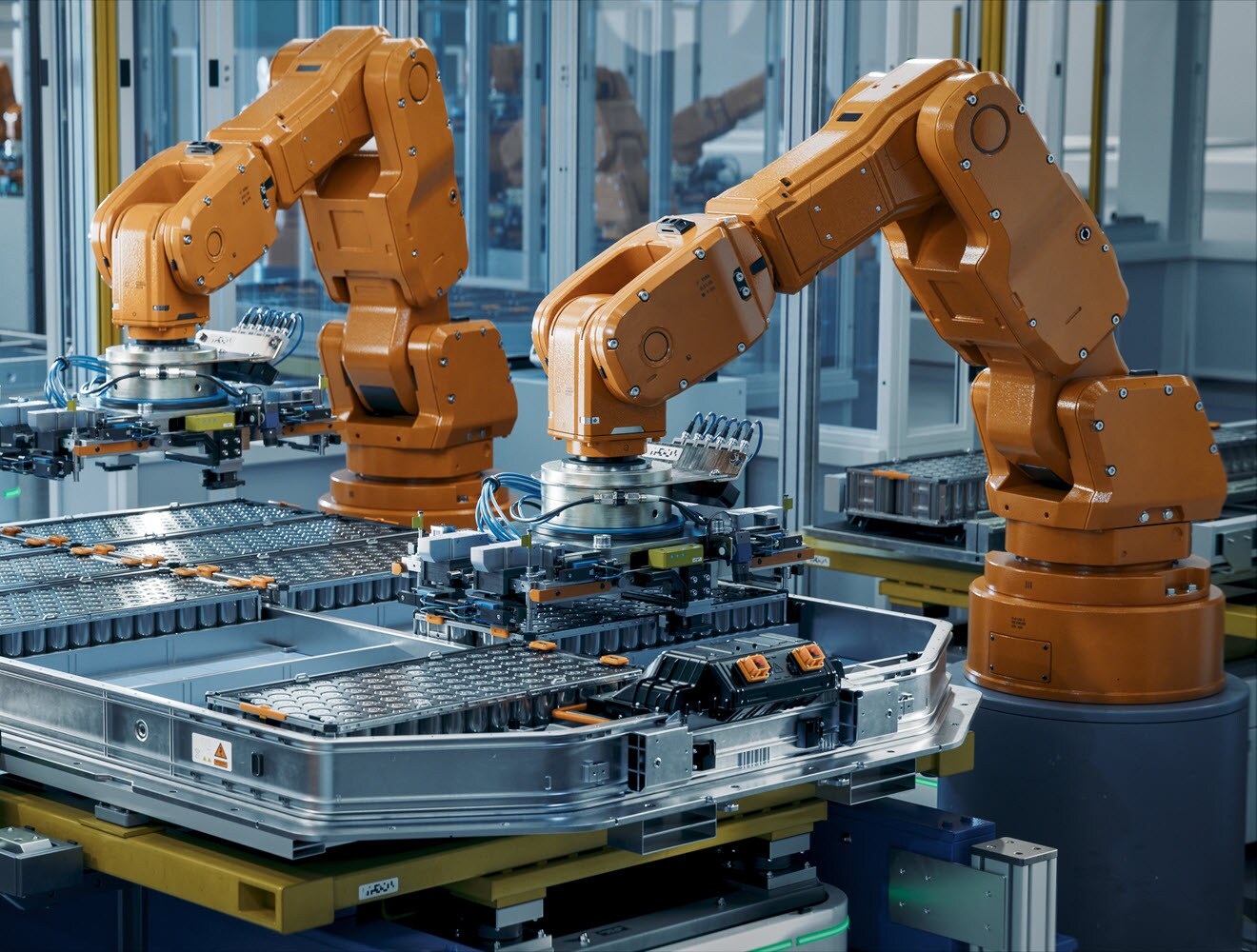

The use of automated machinery and robots to perform repetitive or complex tasks with high precision and efficiency.

Connecting machinery, sensors, and systems to gather and analyze real-time data across the production line, improving decision-making and predictive maintenance.

Creating a virtual model of a physical product or production process to simulate, predict, and optimize performance.

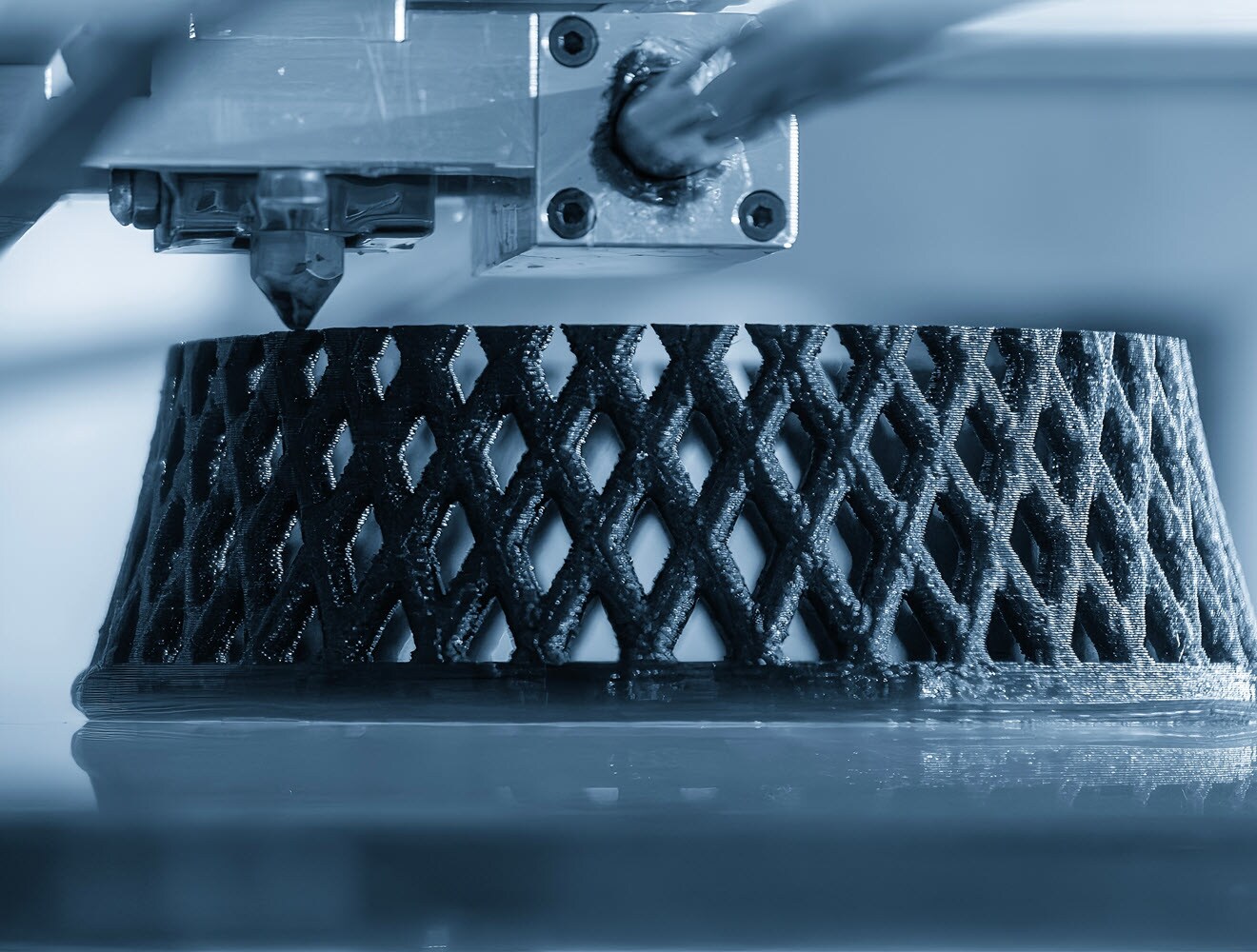

Using 3D printing technologies to produce parts and products directly from digital designs, allowing for rapid prototyping and customization.

Analyzing large sets of data to identify trends, optimize operations, and enhance product quality.

Utilizing cloud-based platforms for data storage, processing, and collaboration, enabling better scalability and accessibility.

When choosing a digital manufacturing solution, it's essential to consider several key factors to ensure it meets your specific needs and enhances your production capabilities.Here are some primary factors to consider:

Implementing Fusion, Autodesk's industry cloud for manufacturing involves strategically integrating its core components to enhance cloud based manufacturing workflows: Fusion for seamless cloud CAD/CAM/CAE/PCB operations, data management, and collaboration, Fusion Manage for robust lifecycle management, and Fusion Operations for real-time insights into shop floor activities.

Complemented by Autodesk Platform Services (APS), extensive APIs, professional-grade extensions, and strategic partnerships, these tools create a comprehensive cloud manufacturing solution that supports every phase of your design and make process.

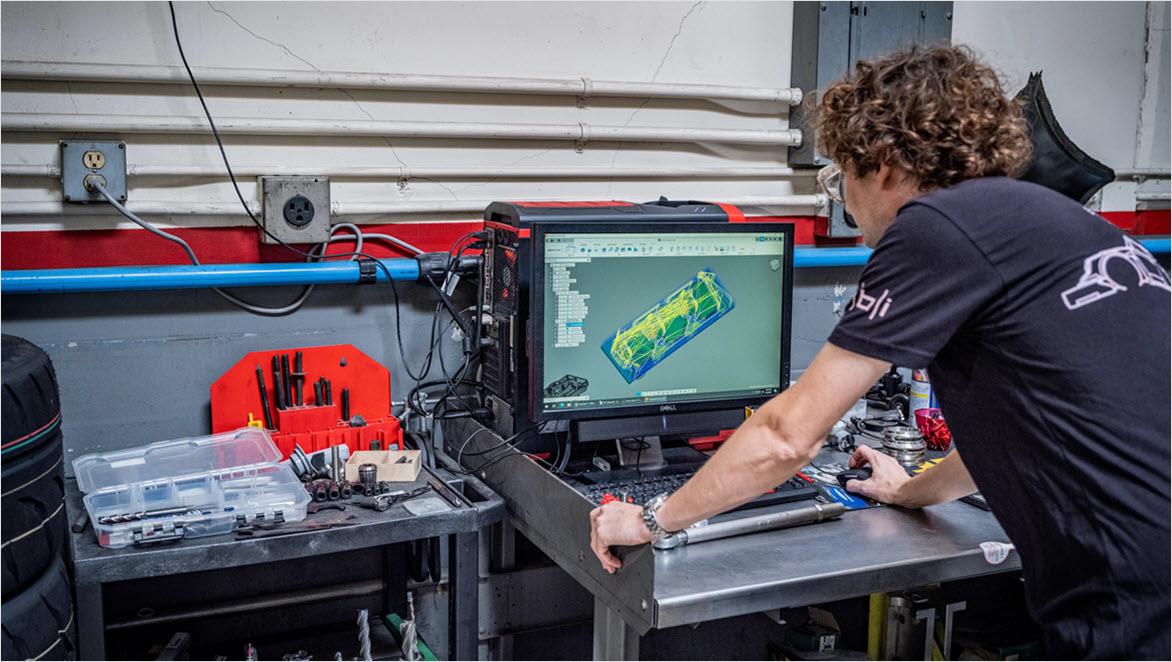

cloud CAD, CAM, CAE, & PCB

Fusion integrates CAD, CAM, CAE, and PCB capabilities into a single platform, allowing users to design, simulate, and manufacture products using cloud-based tools and resources. This enables collaboration, real-time data access, and streamlined workflows across different stages of product development and manufacturing.

Cloud PLM

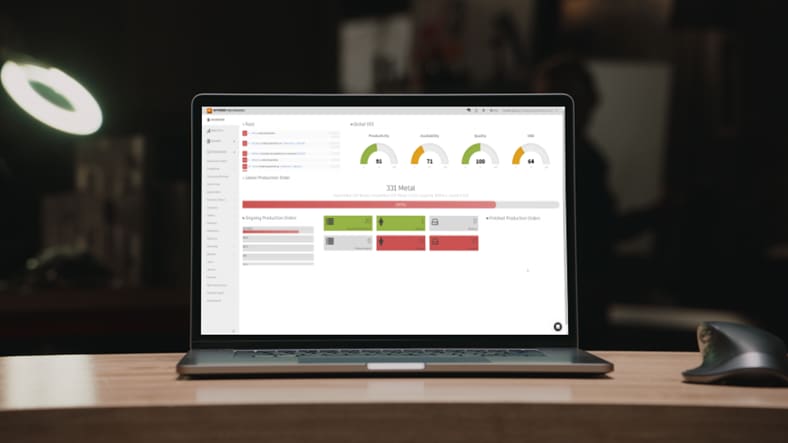

Autodesk Fusion Operations helps manufacturers manage and optimize their production operations, offering features like inventory management, production scheduling, and real-time data analytics. Being cloud-based, it provides the flexibility to access and manage manufacturing processes from anywhere, enhancing collaboration and operational efficiency.

Manufacturing and fabrication insights

Fusion Manage is a cloud-based product lifecycle management (PLM) software that helps manufacturers manage product data, automate workflows, and improve collaboration across the product development lifecycle. Its also includes open API integration with other systems like PDM, ERP, and CRM.

See how Fusion represents Autodesk's commitment to leading digital transformation in manufacturing from innovation to flexiblity.

Explore digital transformation in the context of manufacturing, including ongoing trends and ways to overcome perceived barriers.

Explore digital transformation in the context of cloud based manufacturing, including ongoing trends and ways to overcome perceived barriers.

Learn more about digital manufacturing with these top questions frequently asked by users.

A digital manufacturer leverages advanced digital technologies to streamline and enhance the manufacturing process. This approach encompasses the integration of various digital tools and systems to create a more efficient, flexible, and data-driven production environment.

Digital production involves utilizing advanced digital technologies and processes to create, manage, and optimize the production of goods and services. This approach integrates tools such as CAD for design, automation and robotics for precision tasks, and additive manufacturing for rapid prototyping and customization. By connecting devices through IoT, collecting and analyzing big data, and leveraging cloud computing and AI, digital production enhances efficiency, flexibility, and quality. It enables real-time monitoring, predictive maintenance, and seamless collaboration, ultimately allowing companies to swiftly adapt to market demands, reduce costs, and improve product quality across various industries.

Digital manufacturing technology encompasses the use of advanced digital tools and systems to enhance and streamline the manufacturing process. This includes the integration of CAD software for precise design, automation and robotics for efficient and accurate production, and additive manufacturing (such as 3D printing) for rapid prototyping and customization. Additionally, it leverages IoT to connect machinery and gather real-time data, big data analytics to optimize operations, and cloud computing for scalable data storage and collaboration. By incorporating digital twins for virtual modeling and AI for predictive maintenance and quality control, digital manufacturing technology enables a more efficient, flexible, and data-driven production environment that can quickly adapt to changing market demands and improve overall product quality.

Digital manufacturing offers numerous benefits that significantly enhance the production process. It improves efficiency and accuracy through automation and robotics, reducing the need for manual labor and minimizing errors. The integration of IoT and real-time data analytics allows for better monitoring and optimization of manufacturing operations, leading to reduced downtime and predictive maintenance. Additive manufacturing enables rapid prototyping and customization, shortening product development cycles and catering to specific customer needs. Additionally, digital twins and virtual simulations facilitate advanced planning and problem-solving, while cloud computing provides scalable resources and fosters seamless collaboration across teams. Overall, digital manufacturing enhances flexibility, lowers production costs, and improves product quality, enabling manufacturers to respond swiftly to market changes and maintain a competitive edge.

Yes, Autodesk Fusion is a comprehensive digital manufacturing solution that integrates various advanced tools and features to streamline the entire product development process. It combines CAD, CAM, and CAE capabilities in a single platform, allowing users to design, simulate, and manufacture products efficiently. Fusion supports parametric design, generative design, and direct modeling, enabling rapid prototyping and iterative design processes. Its cloud-based nature facilitates real-time collaboration and access to projects from anywhere. Additionally, Fusion's CAM features provide advanced machining strategies and toolpath generation, making it suitable for both additive and subtractive manufacturing methods. By offering a unified environment for design, engineering, and manufacturing, Autodesk Fusion significantly enhances productivity, reduces time-to-market, and supports the creation of high-quality, innovative products.