& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

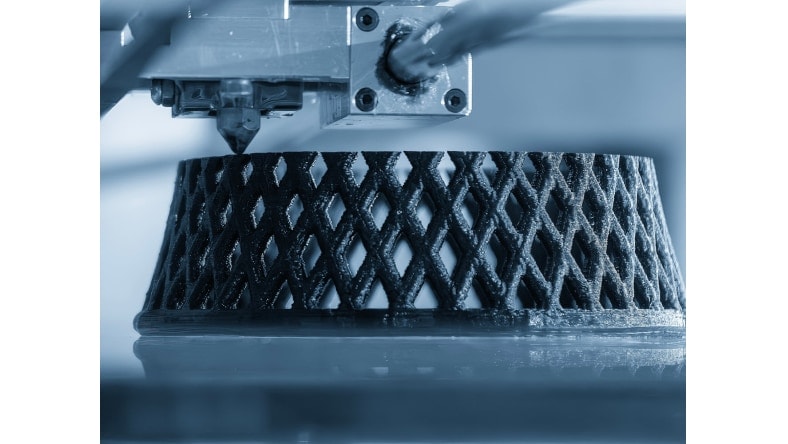

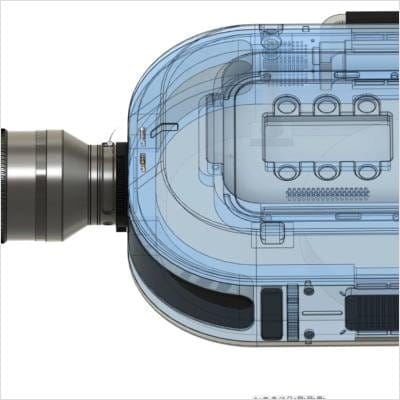

3D modeling software for 3D printing is a tool that helps you create digital designs of objects that can be printed with a 3D printer. It allows you to build and modify virtual models in 3D. These are then converted into formats like STL that a 3D printer or its slicing software can use to produce the physical object. These programs also offer features for ensuring dimensional accuracy of our designs, applying surface textures, and controlling material properties to make sure your design is ready for printing.

3D modeling software is important because it helps you make sure your design will print successfully by allowing you to modify your design and fix any errors before printing. It makes sure the model is optimized for the printer, reducing potential issues such as sharp corners that could cause a part to fracture during the printing process. This step is crucial for saving time, material, and achieving high-quality results in the final printed object.

Choosing the right 3D modeling software is essential for successful 3D printing. Here are four important qualities to consider for the best results.

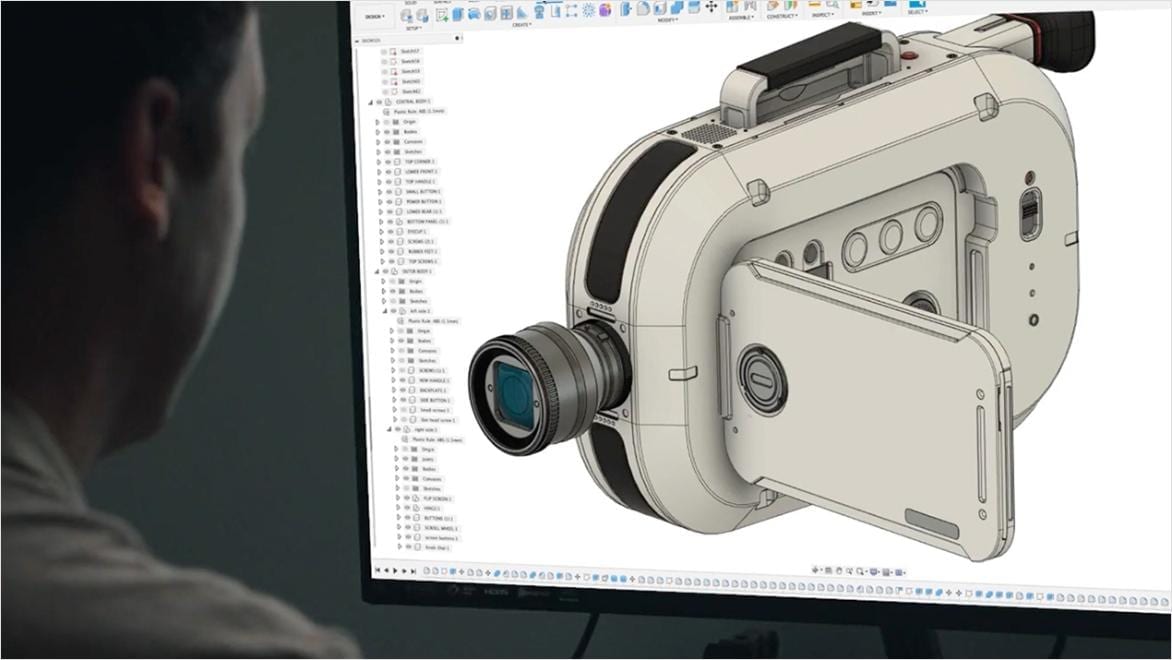

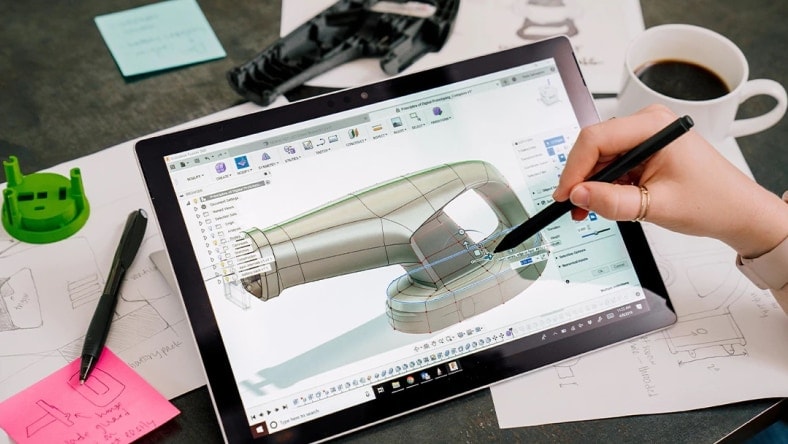

Look for intuitive software with a user-friendly interface, offering straightforward tools for beginners, and advanced options for professionals to streamline the design process.

Make sure that the software provides detailed control over dimensions, geometry, and tolerances, allowing you to create highly accurate models suitable for printing without errors.

Choose software that easily exports files in common 3D printing formats like STL, OBJ, or 3MF to maintain smooth integration with your 3D printer.

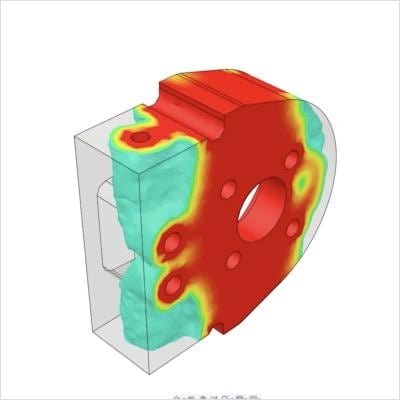

Select software that offers built-in simulation tools, allowing you to test your design’s performance and strength before committing to the actual 3D print.

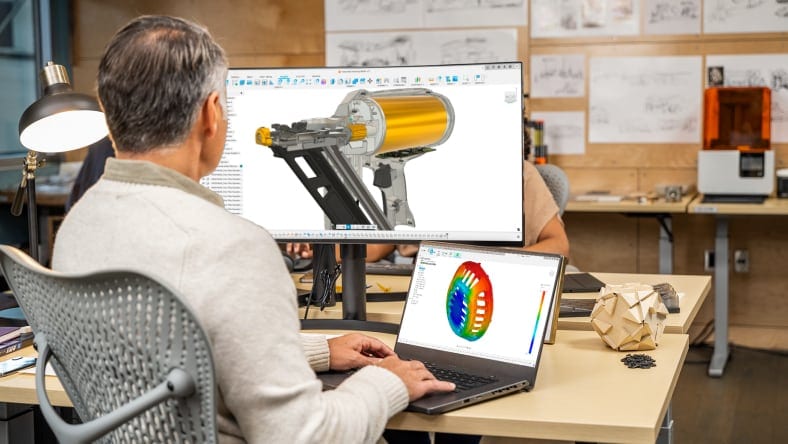

Autodesk Fusion simplifies the 3D printing workflow, accelerating the transition from idea to printed model.

Fusion makes sure that 3D models are designed with high precision, mirroring the intended output for optimal print quality.

The software reduces reliance on physical prototypes by allowing designers to test and optimize digital models before printing.

Fusion’s cloud-based tools facilitate remote teamwork, making collaboration easier, and more effective.

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

Autodesk Fusion is a comprehensive tool for 3D printing design that provides advanced modeling, simulation, and optimization features. It allows you to create detailed 3D models, adjust dimensions, and refine materials, so that your design is ready for printing. With built-in simulation tools, you can test how your model will perform under real-world conditions, helping to prevent structural issues before printing. Autodesk Fusion streamlines the entire process, from designing to preparing models for 3D printing, making it ideal for both complex and high-precision projects.

Autodesk Fusion offers a robust set of features designed to streamline 3D printing. Here are eight key tools to enhance your designs and improve print success.

Fusion’s parametric modeling feature allows you to design with precise, adjustable parameters, maintaining consistent geometry and easy updates across the entire model.

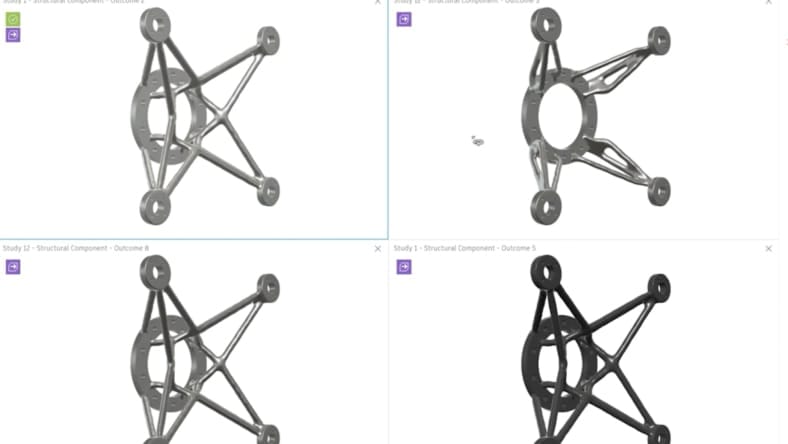

Use generative design to explore multiple design options that maximize material efficiency and structural performance, ideal for creating optimized parts for 3D printing.

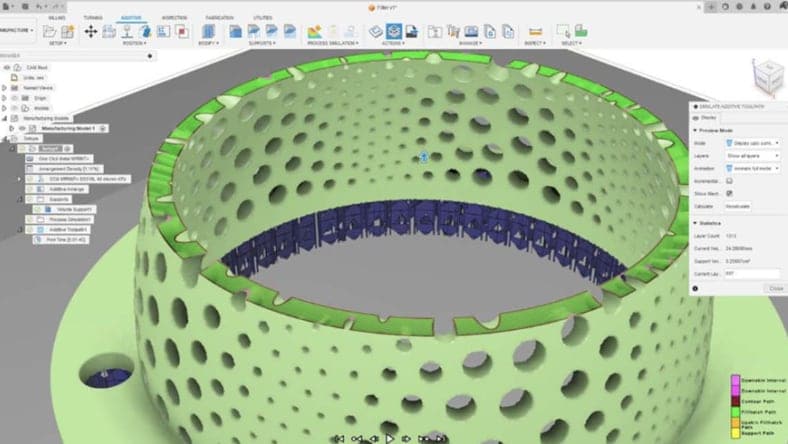

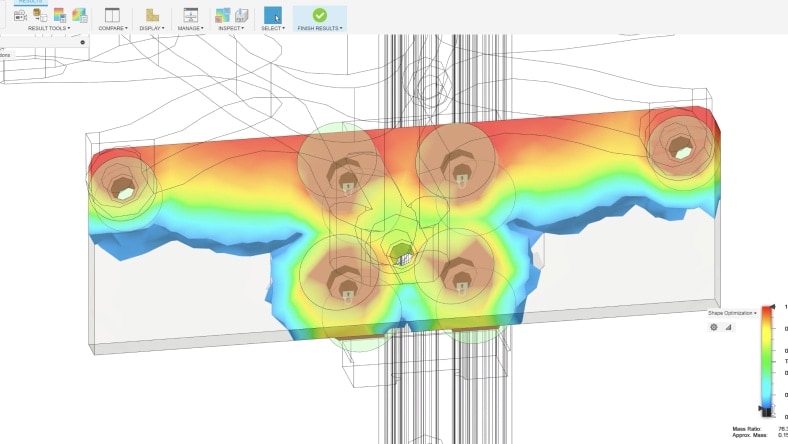

Simulate real-world conditions on your 3D models to predict performance and identify potential issues before printing, reducing the need for physical prototypes.

Fusion’s manufacturing-aware tools help make sure that your designs are suitable for 3D printing, adjusting them for printability, strength, and material optimization.

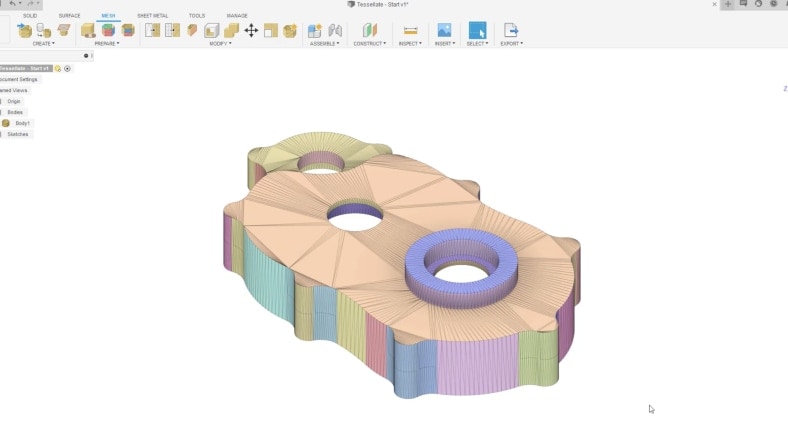

Import, modify, and repair mesh models directly within Fusion, making it easier to work with complex geometries that are often used in 3D printing.

Create lightweight yet strong parts by generating complex lattice structures, which are excellent for reducing material usage while maintaining structural integrity in prints.

Use volumetric modeling to build intricate, high-detail designs, especially for organic shapes or highly detailed parts, making sure that they translate well in the 3D printing process.

Export your models in industry-standard formats like STL, OBJ or 3MF for smooth integration with your 3D printer or your preferred slicer for a seamless transition from design to print.

Autodesk Fusion’s powerful extensions—Fusion Design Extension and Fusion Simulation Extension—add advanced tools to streamline and optimize your 3D printing process, making your designs even more precise and efficient.

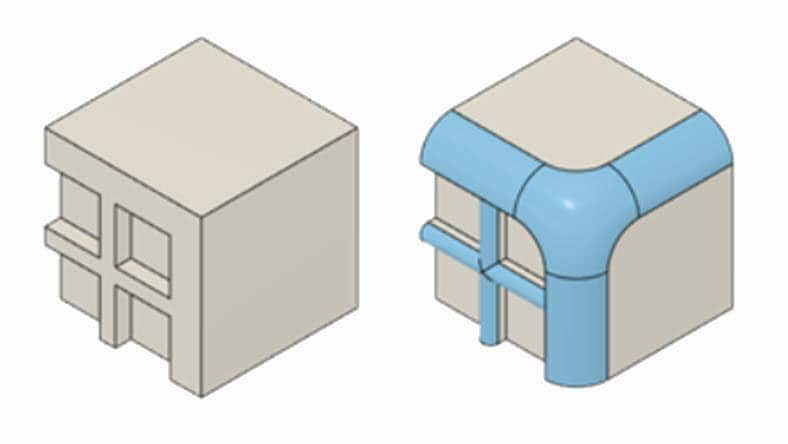

Complex Geometry Creation

Enables the creation of intricate, highly detailed geometries, giving you more control over complex models that are often challenging for 3D printing.

Automation Tools

Automates repetitive design tasks, speeding up the workflow and allowing you to focus on refining designs rather than spending time on manual adjustments.

Manufacturing-Aware Features

Optimizes your designs with built-in manufacturing considerations, so that your model is 3D-printable without sacrificing performance or detail.

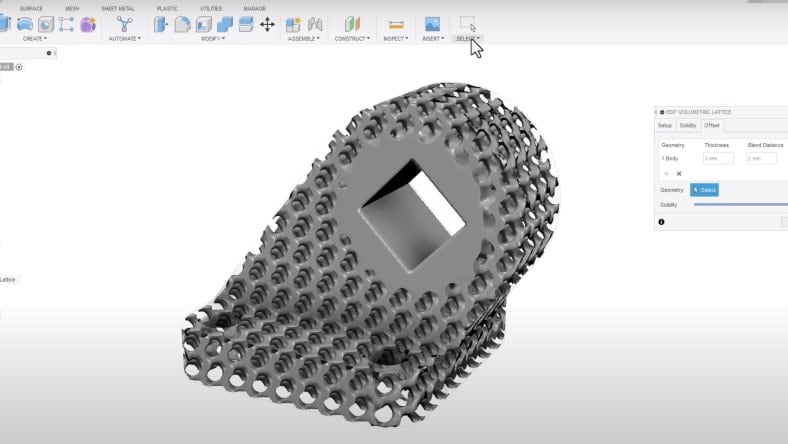

Volumetric Lattice Generation

Helps you design lightweight, strong structures by generating customizable volumetric lattices, ideal for improving material efficiency in 3D printed parts.

Structural Integrity Testing

Allows you to simulate real-world forces, such as stress and load, making sure that your 3D model is strong and durable enough before printing.

Thermal Simulation

Analyzes how heat affects your design, making it especially useful for components that must withstand high temperatures after the printing process.

Generative Design Exploration

Leverages AI to create multiple design variations optimized for both strength and material usage, helping you identify the best solution for 3D printing.

Injection Molding Analysis

Simulates the injection molding process for plastic parts, helping you refine designs that are intended for 3D printing but may later move into mass production.

Find answers to your questions about optimizing your 3D printing experience with Autodesk Fusion.

3D modeling software for 3D printing is a specialized tool that allows users to create and design three-dimensional objects digitally. This software allows users to visualize their ideas in a virtual space, manipulate geometric shapes, and prepare their designs for printing. Autodesk Fusion is a leading example of such software, as it provides a robust set of tools for creating complex models while maintaining compatibility with 3D printers. The software is designed to streamline the workflow from concept to production, making it easier to develop high-quality prototypes and final products.

Autodesk Fusion enhances the 3D modeling process for printing by offering an intuitive interface paired with powerful design tools. Users can create detailed, parametric models, which allows them to make precise adjustments and modifications with ease. The software also integrates simulation tools, enabling users to assess the structural integrity and performance of their designs before printing. This capability is important to make sure that the final product meets functional requirements. Key benefits of Autodesk Fusion include:

Autodesk Fusion includes a range of features tailored specifically for 3D printing. These features facilitate the creation, modification, and preparation of models for optimal printability. Some key features include:

The Fusion Design Extension enhances 3D printing capabilities by providing advanced features for creating complex geometries and optimizing designs for manufacturability. It automates repetitive tasks, allows for easy adjustments, and includes tools for generating lightweight structures, which are ideal for reducing material use without compromising strength.

The Fusion Simulation Extension plays a crucial role in 3D printing by providing advanced simulation capabilities that help predict and optimize the printing process. It allows users to simulate the behavior of materials and the performance of 3D printed parts under various conditions, identify potential issues such as warping or structural weaknesses, and make necessary adjustments to the design before actual printing. This results in improved print quality, reduced material waste, and increased overall efficiency in the 3D printing workflow.

Yes, Autodesk Fusion is well-equipped to handle complex geometries essential for modern 3D printing applications. Its robust modeling tools enable designers to create highly intricate models that are suitable for various industries, including aerospace, automotive, and consumer products. Notable features include:

Autodesk Fusion offers a variety of file export options that are essential for 3D printing. The software supports multiple widely used file formats, ensuring compatibility with different printers and slicing software. Key formats include:

Yes, Autodesk Fusion is user-friendly and offers a range of tutorials and resources for beginners. Its intuitive interface and comprehensive toolset allow new users to learn and create effective 3D models for printing without extensive prior experience.

Autodesk Fusion supports iterative design processes through its parametric modeling features, which allow users to make adjustments to existing designs easily. This is particularly useful in 3D printing, where multiple iterations may be needed to achieve the desired functionality and aesthetics.

.jpg)