& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

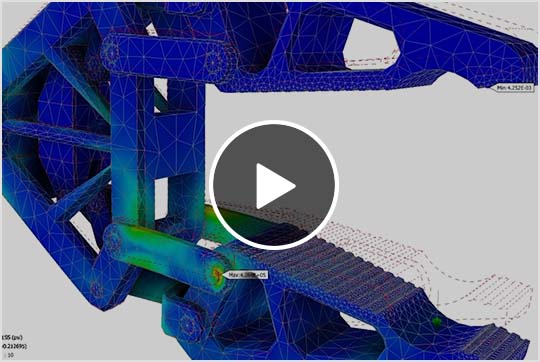

Autodesk Inventor Nastran® delivers finite element analysis (FEA) tools for engineers and analysts.

Powered by the widely accepted Autodesk Nastran solver technology

Wide range of simulation study types for nonlinear, dynamics, heat transfer, fatigue, and more

Highly tested through a comprehensive verification program and documentation set using NAFEMS

Autodesk Inventor Nastran overview (video: 1:42 min.)

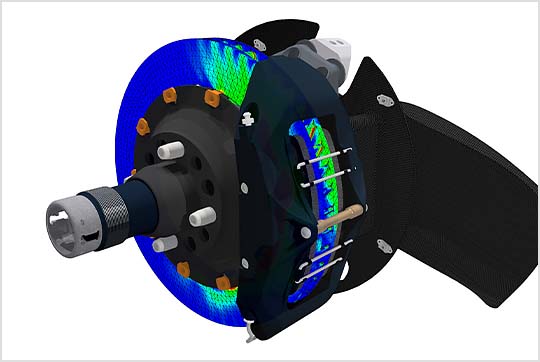

Check for maximum loading conditions with nonlinear buckling

Understand thermal stress, expansion under high temperatures

Check the behavior of your model during a drop test

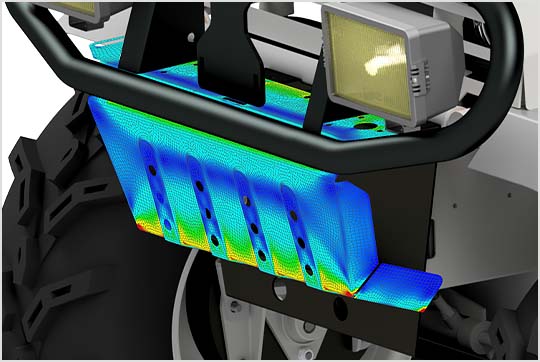

Use specialized mesh elements, result types for sheet metal

Use the Nastran solver to test sheet metal

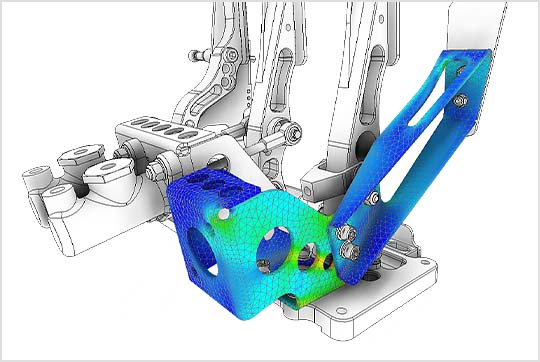

Choose from a complete portfolio of powerful study types to help you optimize your design.

Go beyond linear static study types and analyze the effects of recurring loads in a fatigue study.

Analyze your designs early and often right inside Inventor to reduce the number of physical prototypes.

Include a wide variety of metals, rubber, and soft tissue material models in a single virtual simulation. (video: 4:08 min.)

Autodesk Inventor Nastran offers a wide range of simulation spanning across multiple analysis types such as linear and nonlinear stress, dynamics, fatigue, and heat transfer. It provides a consistent user experience and eliminates the need for multiple single-platform simulation technologies.

Autodesk Inventor Nastran is made to work directly inside Inventor so that all designers and engineers will be empowered to perform simulations on their designs.

Your Autodesk Inventor Nastran subscription gives you access to install and use the 3 previous versions. Available downloads are listed in your Autodesk Account after subscribing. See also previous releases available for subscribers.

Autodesk Inventor Nastran runs on Microsoft® Windows®. See Inventor Nastran system requirements for details.

With a subscription to Autodesk Inventor Nastran software, you can install it on up to 3 computers or other devices. However, only the named user can sign in and use that software on a single computer at any given time. Please refer to the Software License Agreement for more information.

Launch your trial software and click Subscribe Now on the trial screen or buy Inventor Nastran here. When buying your subscription, enter the same email address and password combination you used to sign in to your trial. Learn more about converting a trial to a paid subscription.

Inventor Nastran is available through the Product Design & Manufacturing Collection. The price of the Product Design & Manufacturing Collection subscription is