& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Reaeration boosts dissolved oxygen in rivers, and is crucial for water quality.

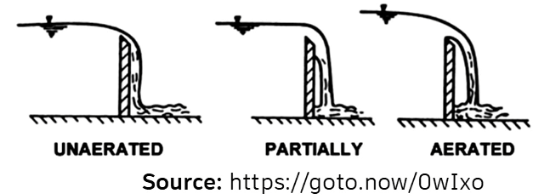

Hydraulic structures create white water and turbulence, promoting oxygen transfer.

In InfoWorks ICM, hydraulic structures (excluding pumps) are seen as control links for their effect on water quality and oxygen levels. For instance, a weir disrupts the water surface, promoting reaeration by increasing turbulence and oxygen diffusion.

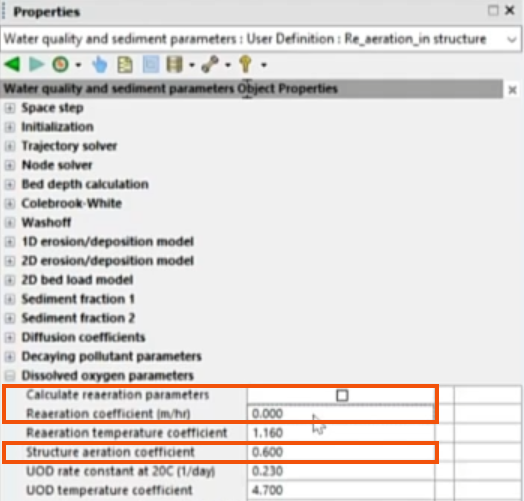

In ICM, there are two options for defining reaeration coefficients:

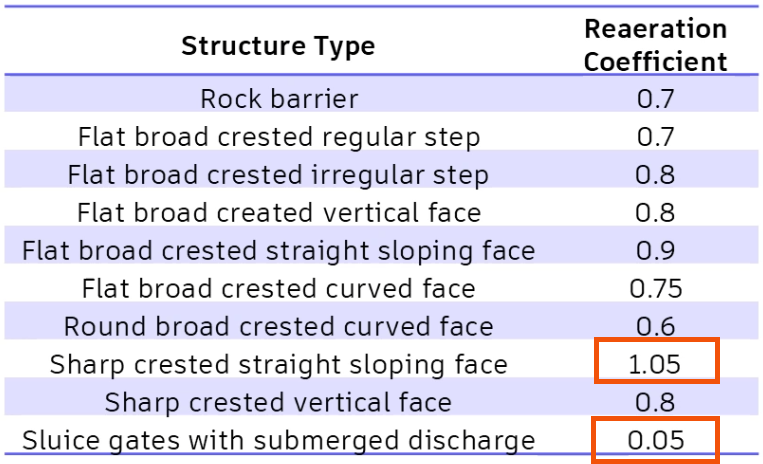

The reaeration coefficient depends on multiple factors, including structure type, head loss, temperature, flow, turbulence, and flow conditions.

For example, reaeration over a weir occurs through four processes:

The reaeration coefficient also varies by structure type. Sluice gates with submerged discharge have low reaeration coefficients, as they limit air-water interaction, whereas sharp crested weirs with a sloping face have higher coefficients, promoting efficient oxygen transfer.

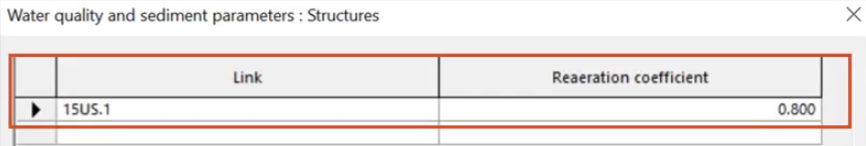

Different structure types can be assigned specific reaeration parameters in ICM to help ensure accurate modeling of dissolved oxygen dynamics.

Structures such as sharp crested weirs with a straight sloping face have the highest reaeration coefficient at 1.05, due to significant turbulence and air entrainment. Conversely, sluice gates with submerged discharge have minimal reaeration with a coefficient of 0.05.

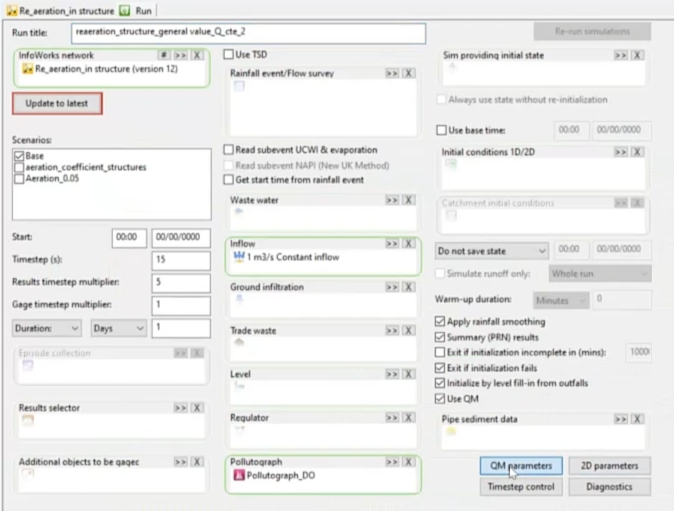

Next, create two different scenarios: one where the reaeration coefficient is defined with a uniform value, and one where the coefficient is defined with a custom value for a specific structure—in this case, an irregular weir. Then, compare the two scenarios, which have the same constant flows, to analyze the effect of reaeration on dissolved oxygen levels.

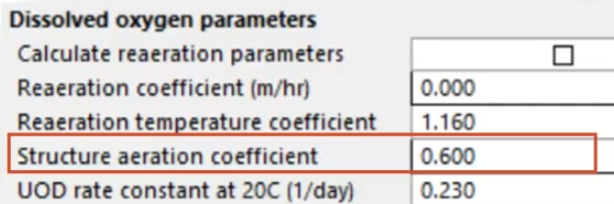

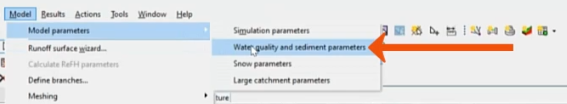

To define the reaeration parameters for the general, or uniform, value:

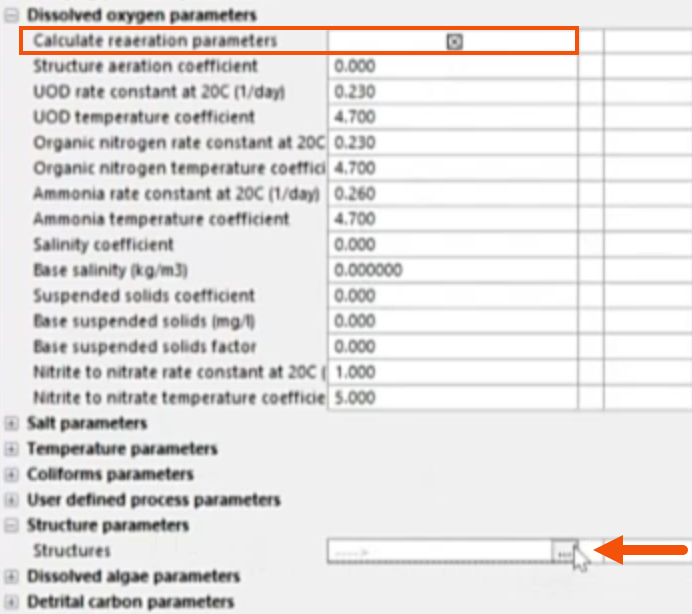

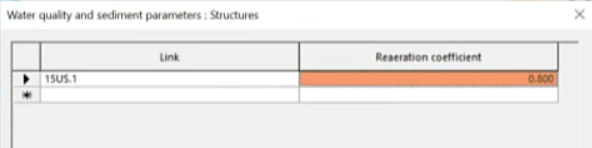

Now, create the second scenario with a reaeration coefficient that is customized to the irregular weir.

Remember that reaeration rates are impacted by reaeration coefficients and by the different hydraulic structures.

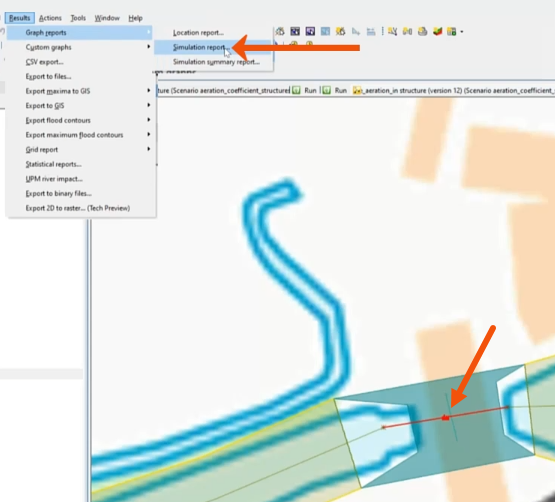

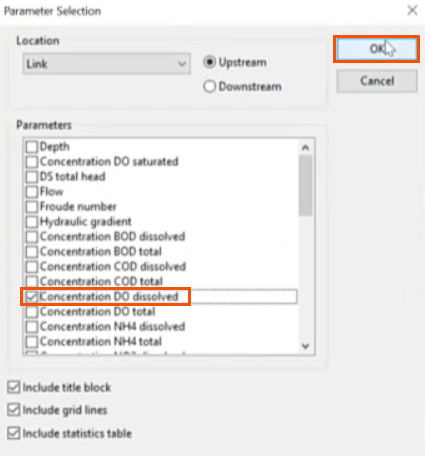

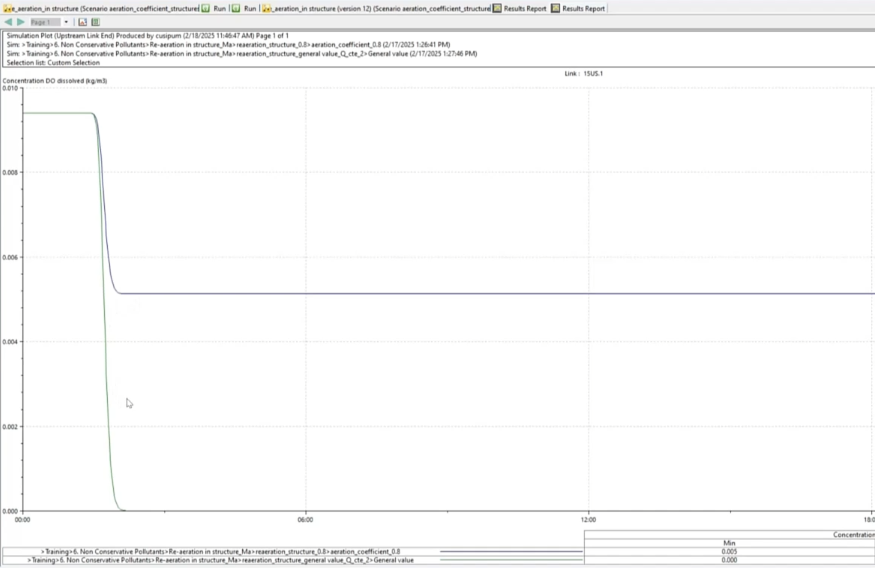

Compare the results of the two runs, with and without structure-specific reaeration coefficients, to analyze the changes in the dissolved oxygen concentration.

When the reaeration coefficient is set as a global value for the structure, the dissolved oxygen concentration drops to zero.

When the value for each hydraulic structure is set individually, the concentration does not drop to zero, and a constant value is maintained.