& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

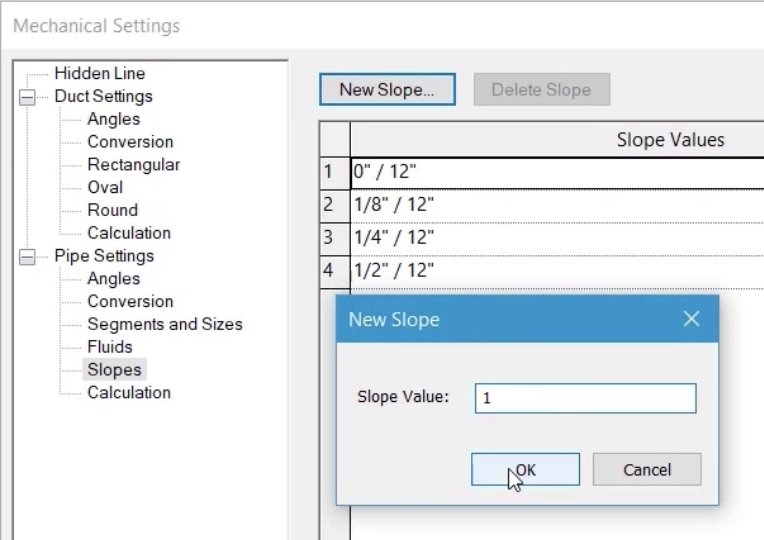

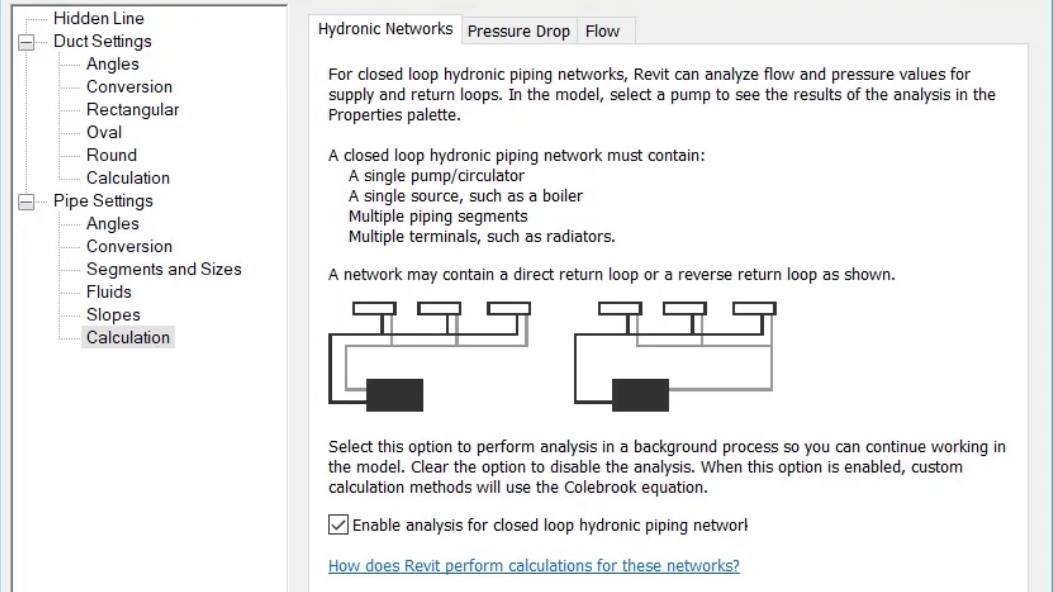

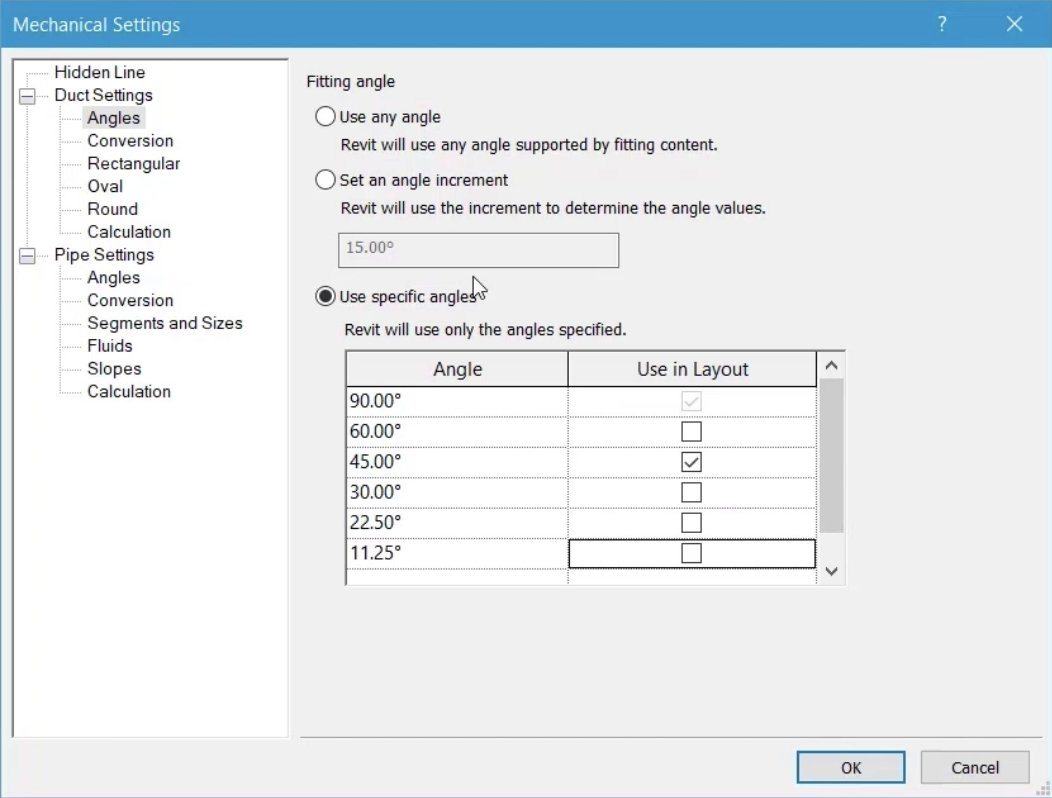

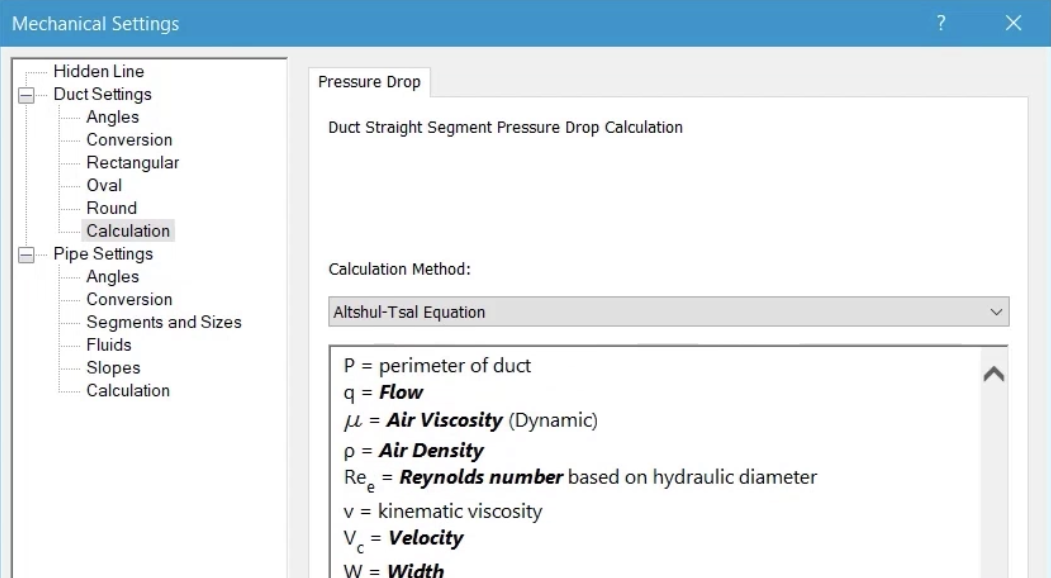

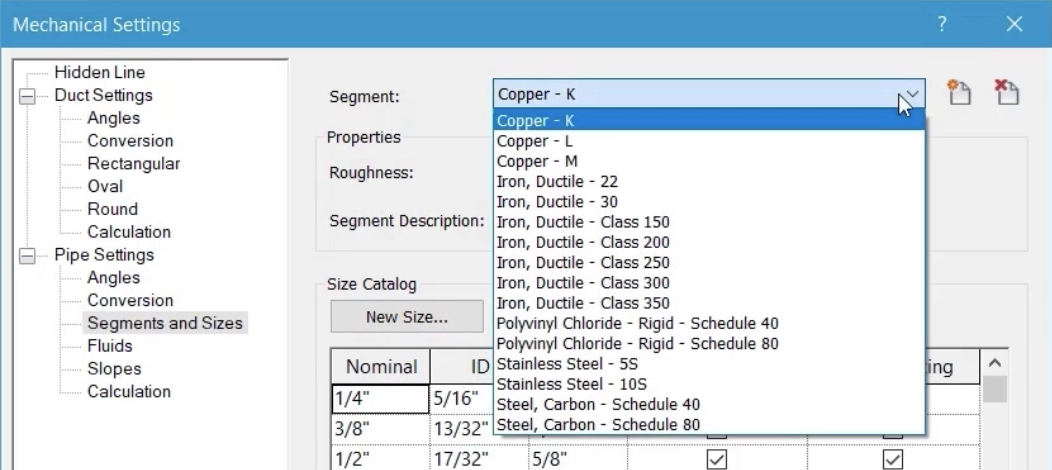

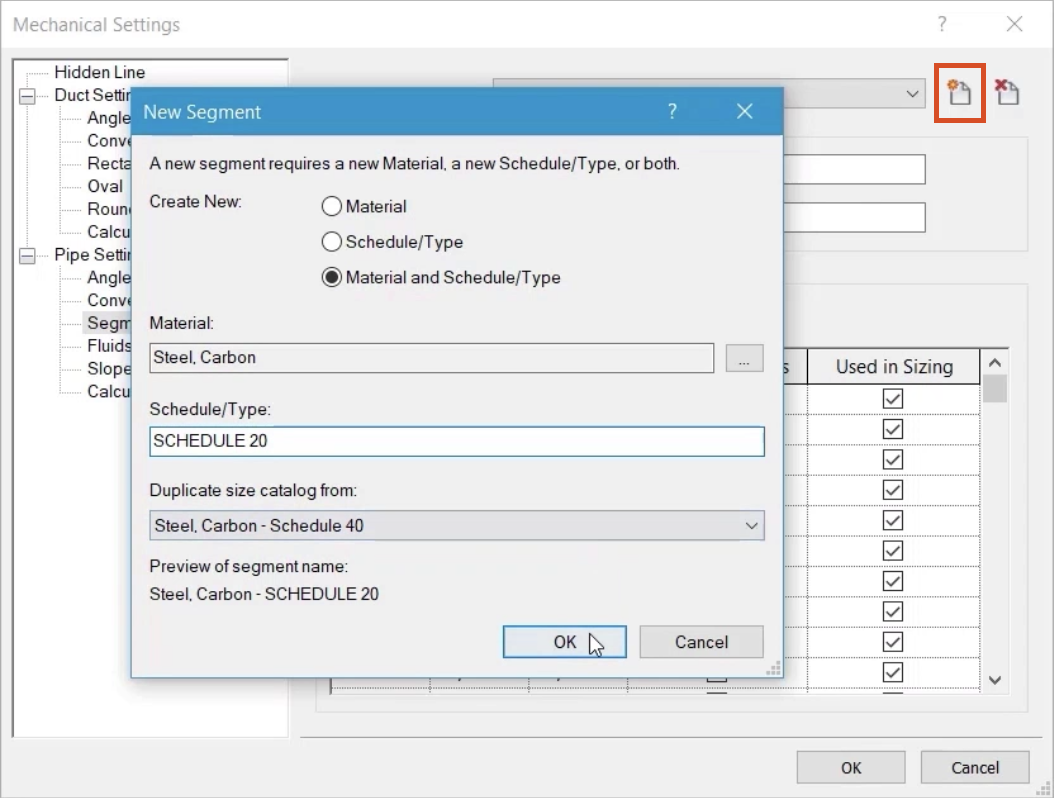

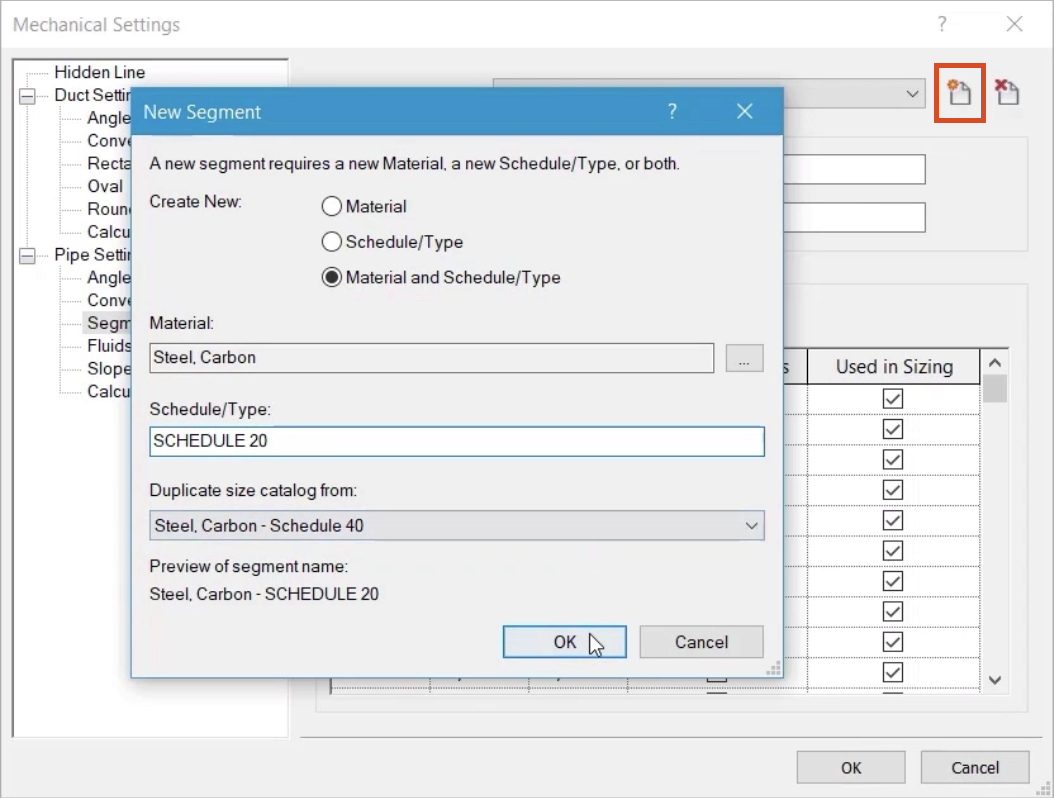

Access and review the key settings and options for duct and pipe standards.

Access and review the key settings and options for duct and pipe standards.

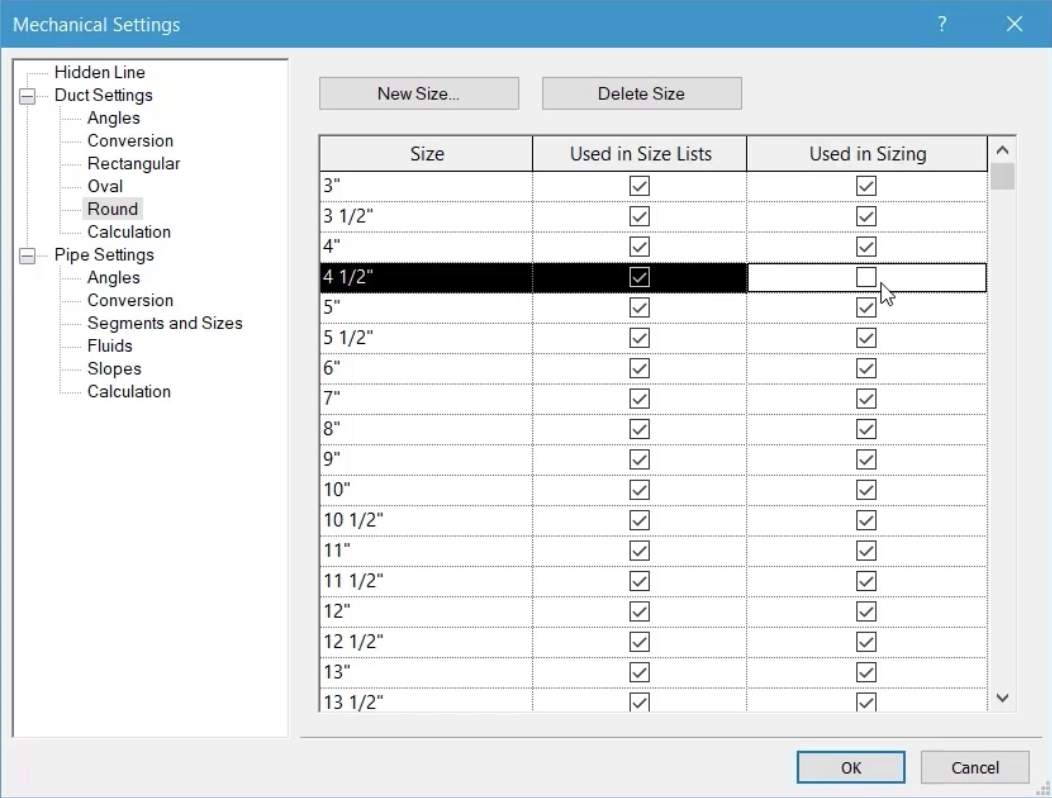

This allows the user to select this size, but prevents it from being selected when using the duct sizing tools.

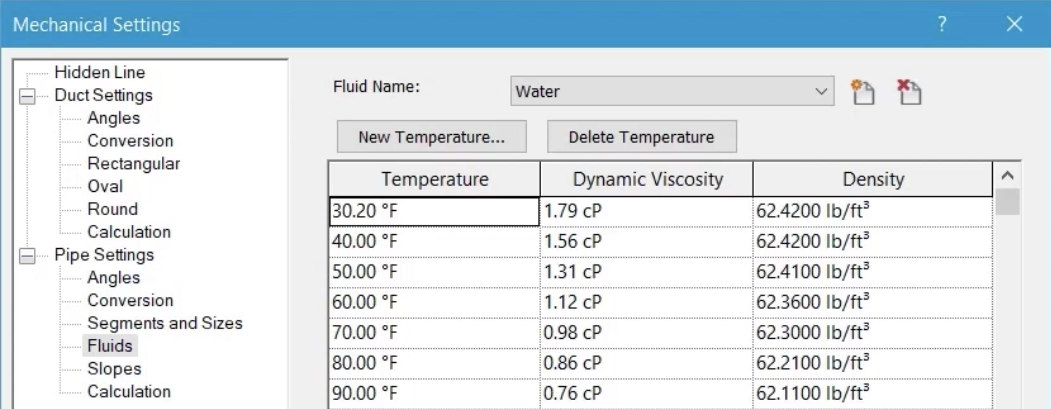

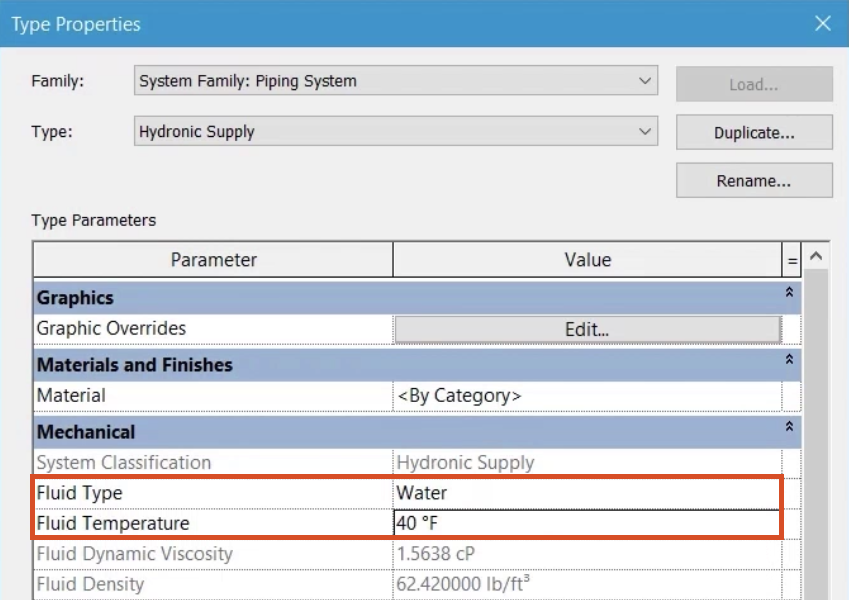

Fluids are applied to piping systems, and their properties will have a bearing on the outcome of any pipe sizing that is carried out.