& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

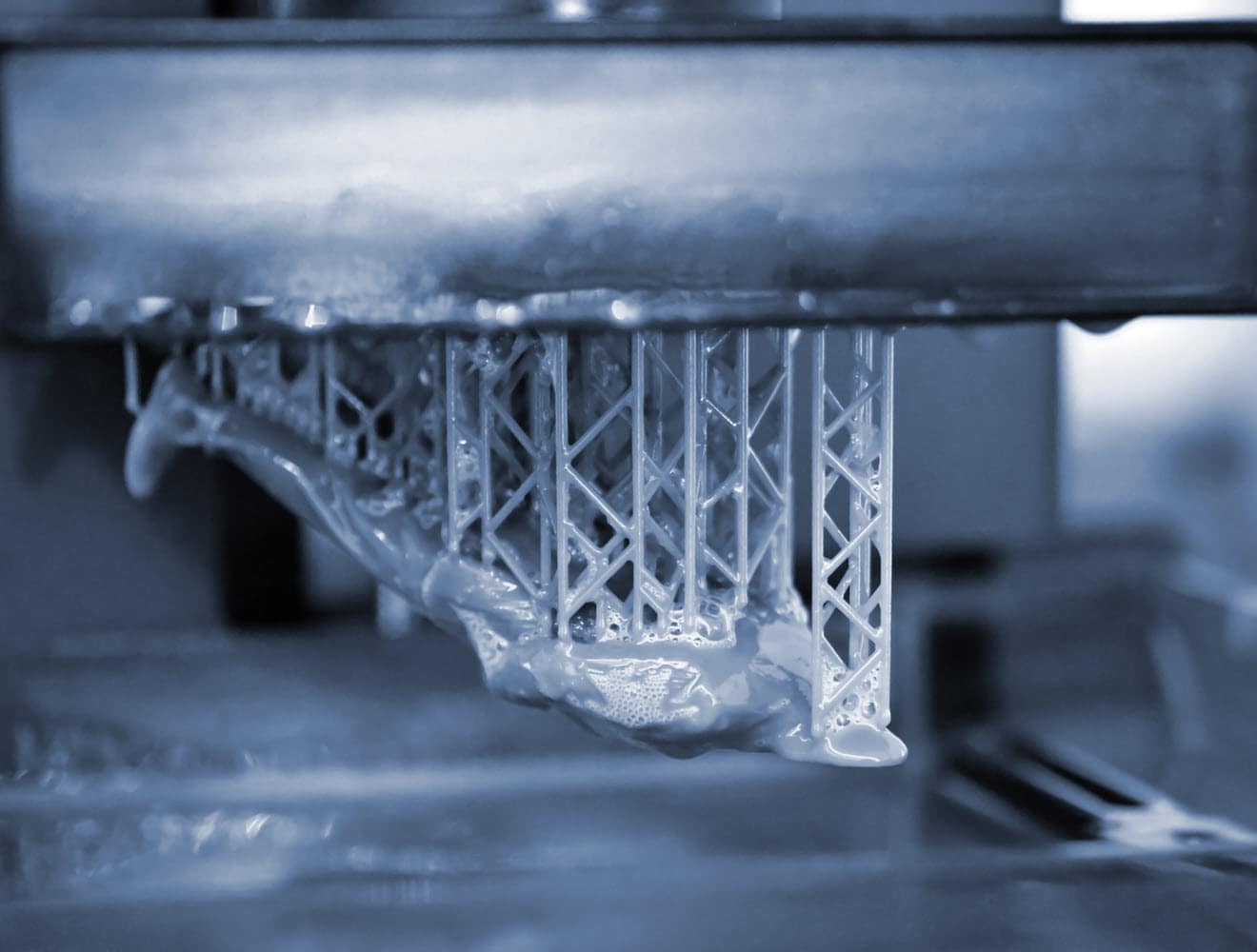

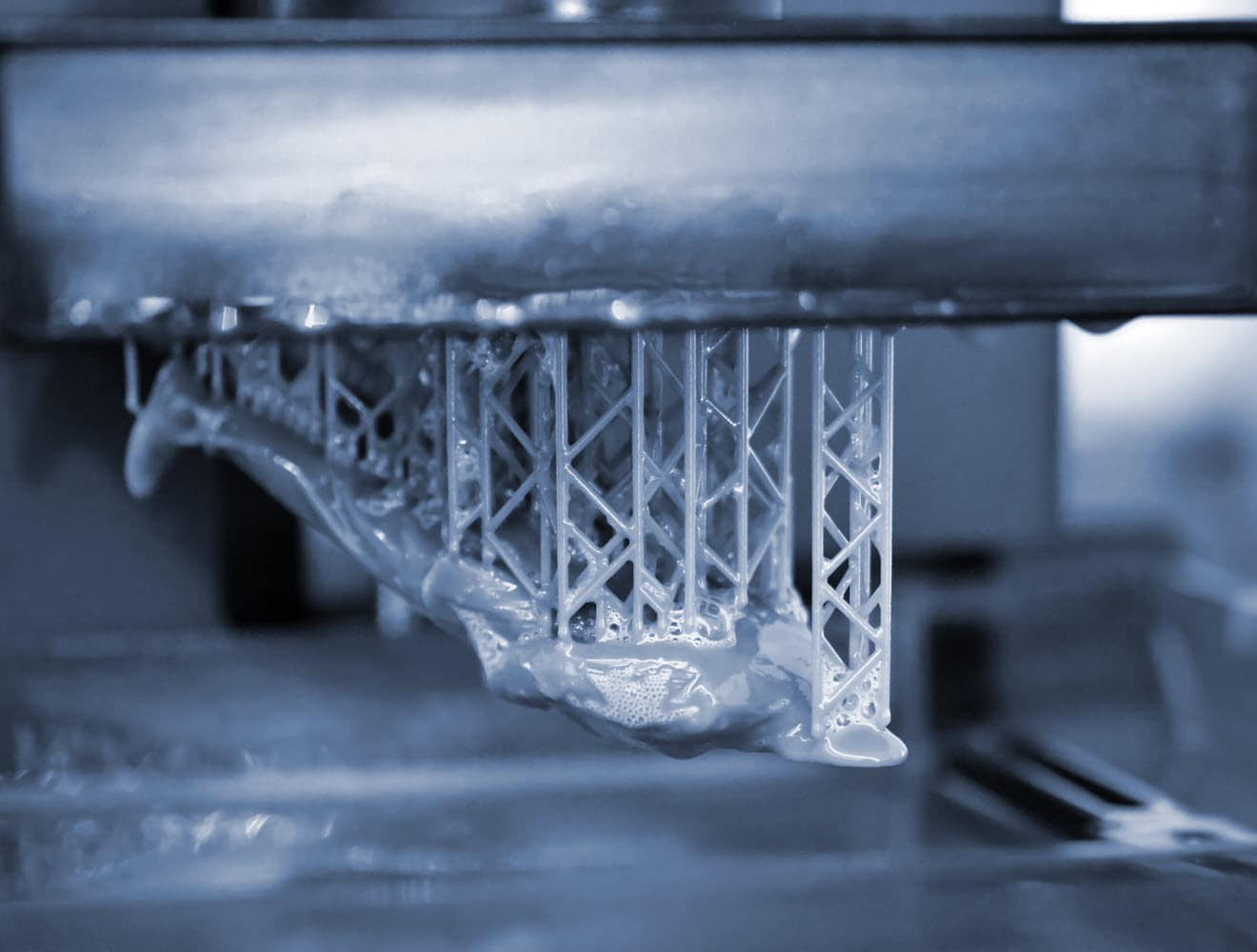

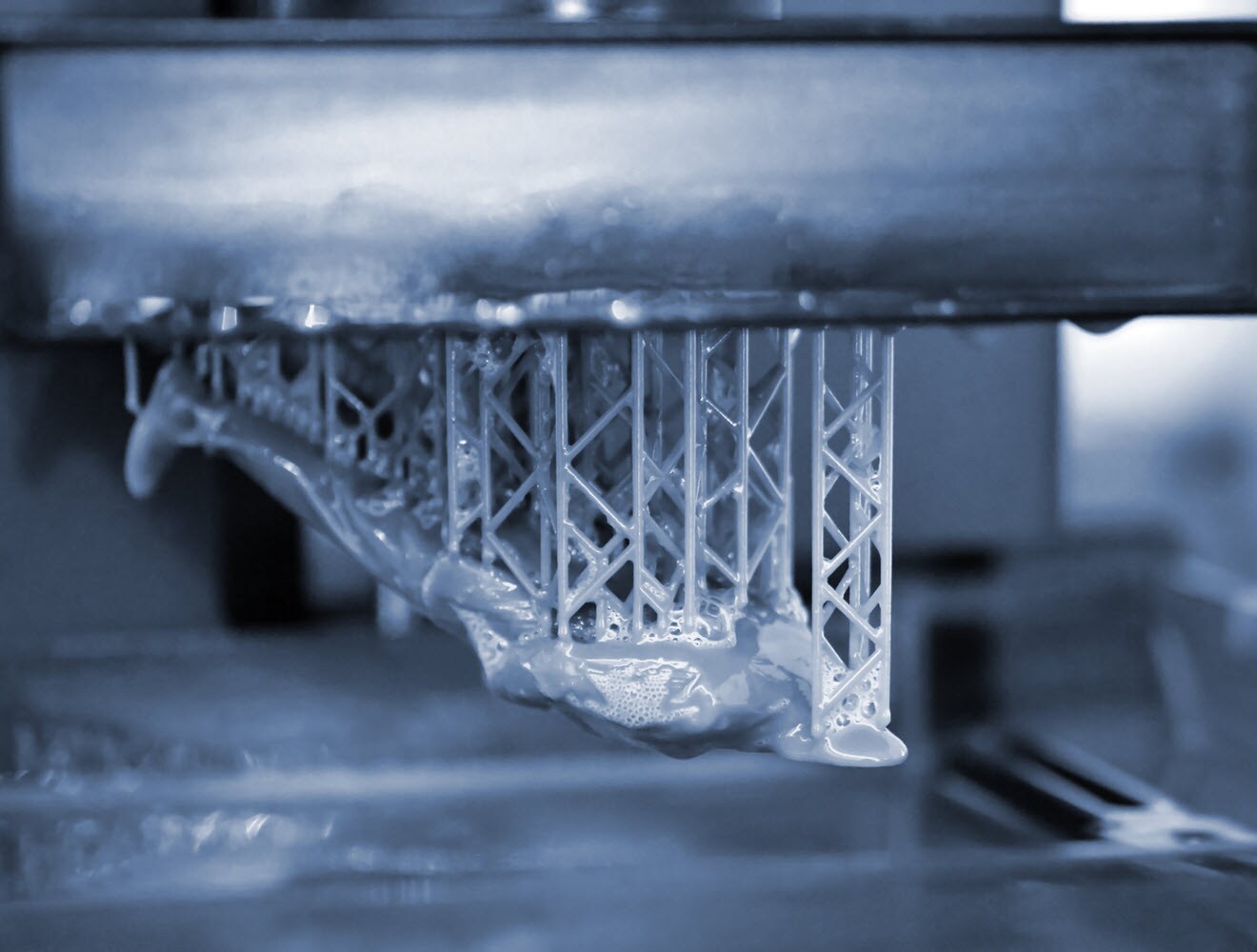

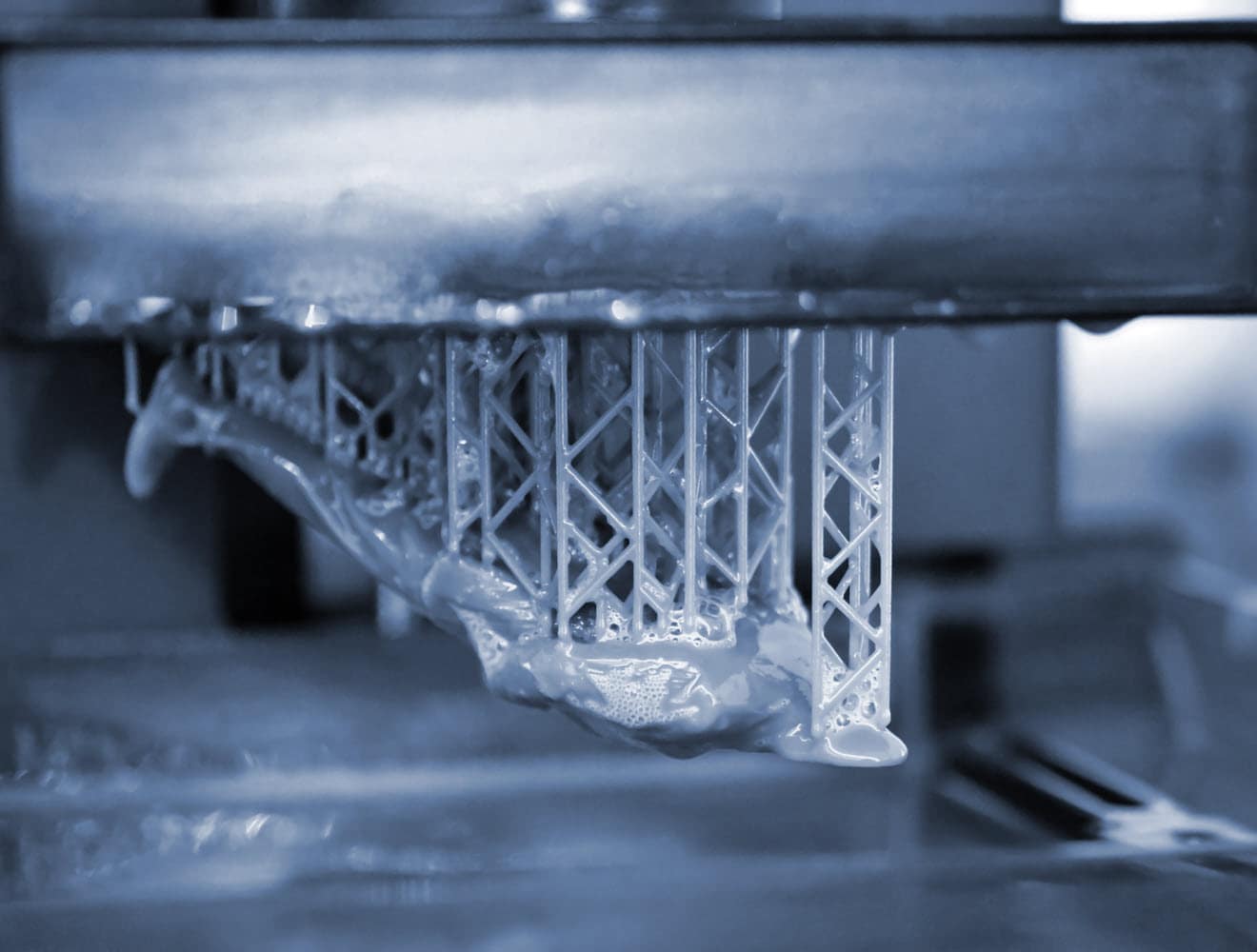

Stereolithography (SLA) is an advanced additive manufacturing technique that turns liquid resin into solid, polymeric structures using an SLA 3D printer. This process involves directing a laser beam onto the surface of the liquid resin to selectively cure and harden it layer by layer. This results in the creation of intricate and highly precise 3D objects.

SLA is renowned for its ability to produce fine details and smooth surface finishes. This makes it ideal for prototyping, medical models and complex computer hardware components. Designers and engineers can rapidly iterate and refine their designs, while speeding up the development cycle and improving the quality of the final product.

SLA works through a process called photopolymerisation, where a laser cures and solidifies liquid resin to form a 3D object. Here are the steps involved:

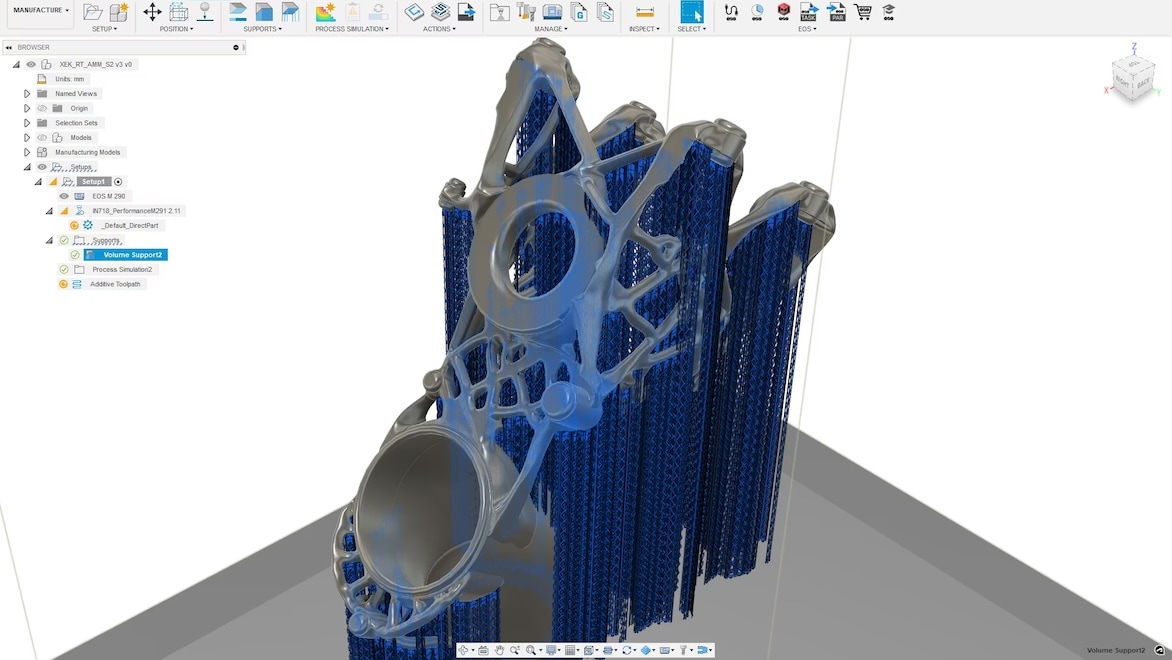

A digital 3D model is created using CAD software. The model is then sliced into thin layers using specialised SLA printing software.

A vat or tank is filled with liquid photopolymer resin. The resin used varies on the desired properties of the final object, such as flexibility, strength or transparency.

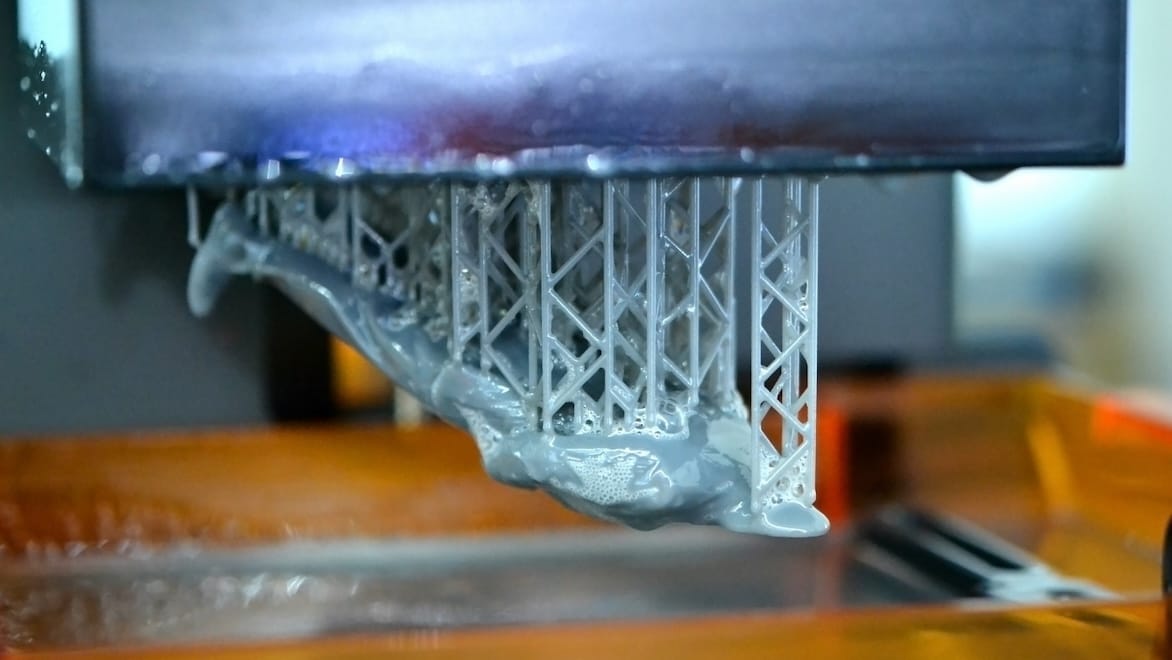

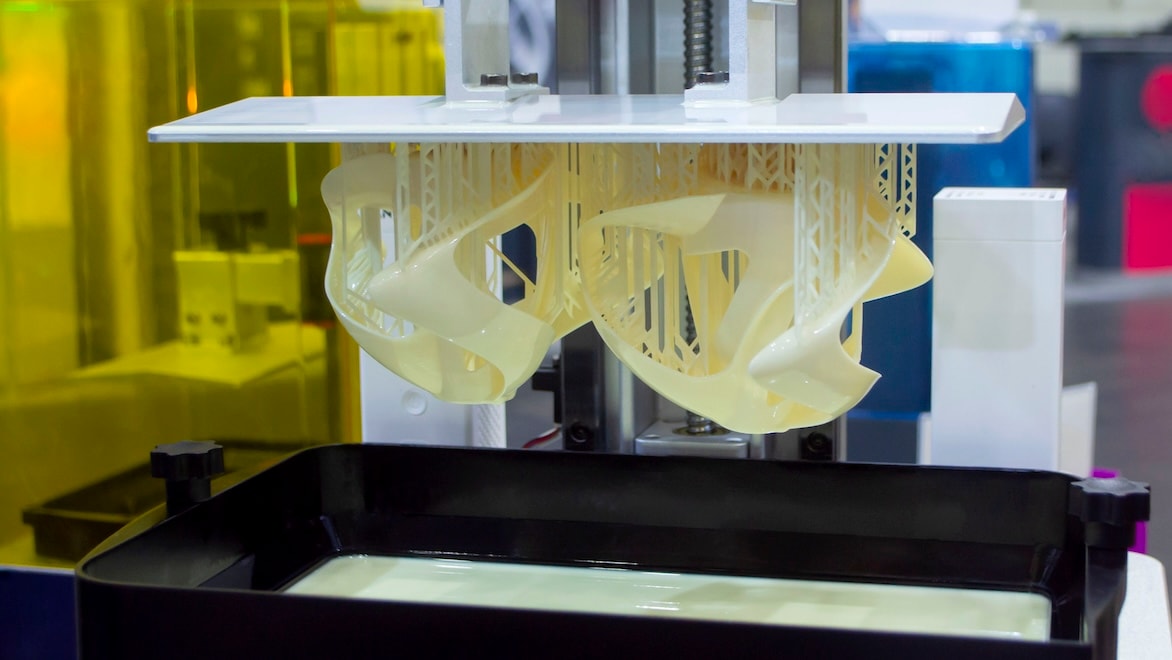

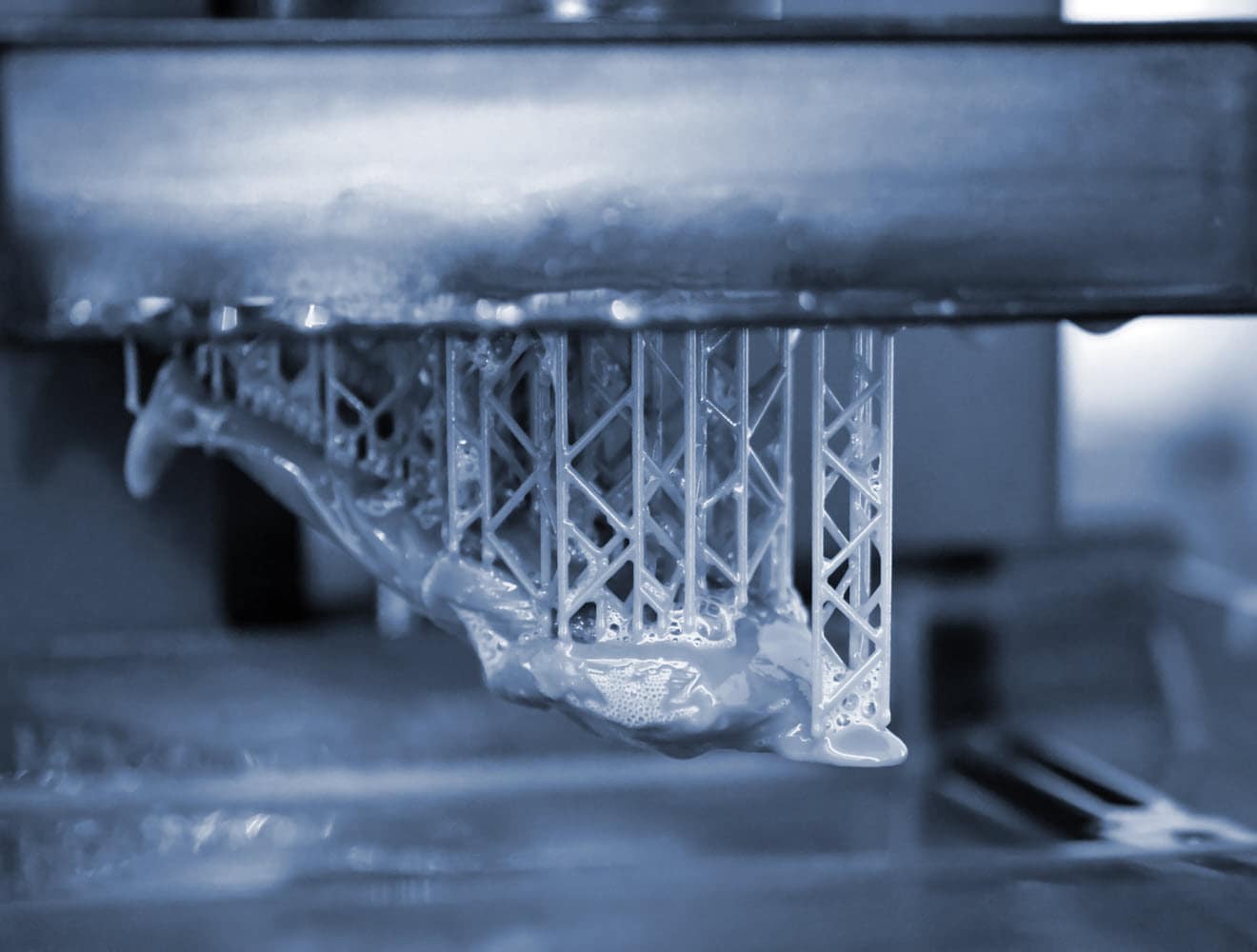

The SLA printer uses a laser to selectively cure the resin layer by layer. The laser traces the cross-sectional pattern of the object on the surface of the liquid resin. This causes the resin to solidify wherever the laser touches.

After a layer is cured, the build platform lowers, allowing a fresh layer of liquid resin to cover the previously cured layer. The process is repeated, with the laser curing each new layer, until the entire object is formed.

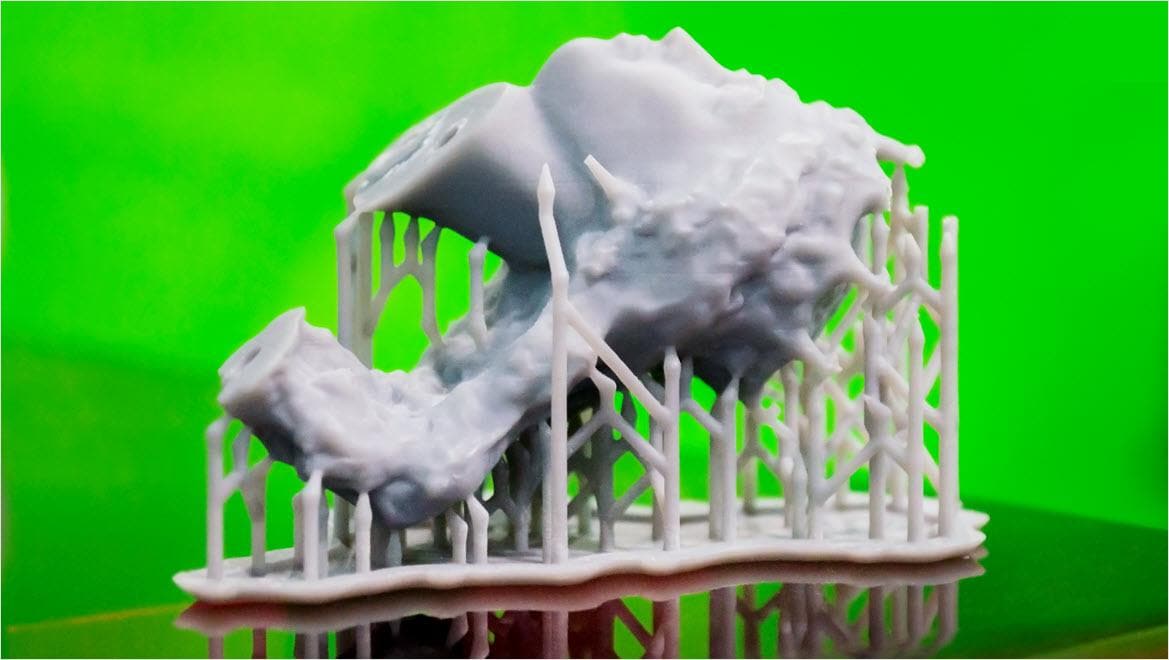

Once printing is complete, the object is removed from the vat. Post-processing steps include rinsing to remove uncured resin, further curing in a UV oven, and processes like sanding or painting.

The result is a highly detailed and accurate 3D object, ready for prototyping, testing or final use.

SLA 3D printing is valued for its precision, ability to create complex geometries and smooth surface finishes, making it suitable for a wide range of applications.

Some 3D-printing methods produce rough builds and require postproduction processing to improve the surface finish. Therefore, those methods are often only used for size or dimensional testing. Stereolithography, however, lets manufacturers build finer finishes into their complex geometry print designs, minimising post-processing steps.

Other 3D-printing methods produce variations in their layers that result in rough surfaces, but stereolithography has isotropy, or uniformity, between its layers due to how new layers bond to the cured layers. This uniformity results in minimal variation between layers, making SLA one of the few single-state additive production processes, resulting in less post-manufacture cleaning or polishing.

SLA 3D printers can use multiple resin tanks, which means manufacturers can print objects with different colours or slightly different materials in one pass. The product created is immediately ready for use or print areas of varying flexibility in a single structure.

To create anything using stereolithography, special 3D printing software is required that facilitates the digital design of your part or model before it is brought to life using UV light and resin. One of the most popular stereolithography software solutions is Autodesk Fusion (US Site), CAD/CAM software offering a comprehensive design environment that links straight into the manufacturing process. Autodesk has also teamed up with 3D printer manufacturer Formlabs (US Site) to ensure a smooth workflow from design to print.

The stereolithography process differs from other popular 3D-printing methods in several ways.

Fused deposition modelling (US Site) (FDM) uses a thread or filament of thermoplastic in solid form, melting and extruding it onto the 3D model.

Selective laser sintering (US Site) (SLS) also uses polymers, but the material is a powder. The 3D printer aims a laser at the powder, melting the polymer and fusing it into a solid form for the final structure.

FDM is most widely used in the prosumer/consumer and small-manufacturing markets alongside stereolithography. In contrast, SLS is more suited to heavy industry.

Among each type, stereolithographic printing produces the smoothest, highest-resolution surface with material that’s watertight and reasonably shock absorbent in its final state. These properties make it the most popular method among home users and hobbyists. The number of desk toys and trinkets produced in the early home 3D-printing movement are good examples of stereolithography’s utility.

The chemical properties of stereolithography resins also make them popular in aesthetic and artistic fields, like jewellery and accessories. In addition, SLA is also widely used for making biomedical devices because of the resins’ nonabrasive finish.

The stereolithography process is particularly well-suited to prototyping because it allows for quick production of single parts. SLA prototypes also offer a high level of accuracy without the need for expensive tooling. Building prototypes in this way can reduce time to market and encourage creativity and experimentation during the design process. Coupled with versatile design software like Autodesk Fusion, stereolithography can reinvigorate your prototyping processes.

Many different industries use stereolithography 3D printing for a large range of practical applications. In the health care sector (US Site), it has been used to create medical devices (US Site) tailored to the specific needs of the patient, such as orthotics and prosthetics. The automotive industry (US Site) has used SLA 3D printing for rapid prototyping and customised parts. Similarly, Aerospace (US Site) manufacturers trust it to create cost-effective, safe and reliable parts. Stereolithography has also enhanced the jewellery industry (US Site), allowing for the design and production of highly intricate and personalised pieces.

DR. HANNES SCHWENKE

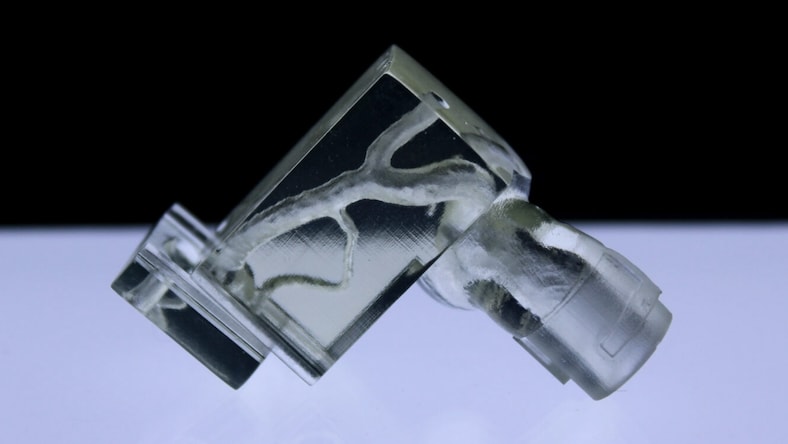

A German neurosurgeon and team have improved their outcomes for brain aneurysm surgery. They've used stereolithographic 3D-printed models of the patient’s arteries—created with Fusion and Formlabs (US Site) —to visualise, analyse and test their surgical plans.

PRINTCITY

Using Autodesk Fusion and a fleet of printers offering SLA, FDM and metal printing technologies, this additive manufacturing and digital manufacturing facility in Manchester, UK, guides clients through rapid prototyping and feasibility testing.

COSM MEDICAL

To help address the often-stigmatized women’s health issue of pelvic floor disorders, this medical device company is creating customised intravaginal prosthetics using ultrasound technologies, AI, Autodesk Fusion and Formlabs SLA printers.

Stereolithography (SLA) and fused deposition modelling (FDM) are both popular 3D printing technologies but differ significantly in their processes. SLA uses a laser to cure liquid resin layer by layer, resulting in highly detailed and smooth surface finishes, ideal for intricate designs and prototypes.

FDM extrudes thermoplastic filament through a heated nozzle. It builds objects layer by layer from the bottom up, which is generally more cost-effective and suitable for functional parts.

Overall, SLA excels in precision and surface quality, while FDM is preferred for its affordability and versatility in material choices.

Stereolithography (SLA) was invented by Charles Hull in 1984. Hull, who co-founded 3D Systems, patented the technology and introduced the first commercial SLA 3D printer. This allowed for the creation of 3D objects by curing photopolymer resin with ultraviolet light, layer by layer, enhancing prototyping and manufacturing processes.

SLA technology began to gain traction in the 1990s, mainly for rapid prototyping. Engineers and designers used its ability to create accurate and detailed models quickly, enhancing product development cycles. Advances in resin materials also began to expand the range of applications.

SLA printers became more accessible and began to see wider adoption beyond prototyping. The medical, dental, automotive and aerospace industries began utilising SLA for creating complex, custom parts.

SLA became increasingly popular for producing end-use parts, not just prototypes. More durable and specialised resins enabled the production of functional components for various industries, solidifying SLA’s role in additive manufacturing.

SLA continues to improve in speed, precision and material diversity. It remains a key technology in 3D printing, with ongoing research and development pushing the boundaries of what can be achieved.

Stereolithography (SLA) significantly contributes to sustainability in multiple ways. Using photopolymer resin with precision reduces material waste compared to traditional subtractive methods. The energy consumption of SLA printers is also typically lower than conventional manufacturing equipment.

The rapid prototyping capability of SLA minimises waste and resource use associated with extensive physical prototypes. SLA printing also offers localised and on-demand production, decreasing transportation needs and the associated carbon footprint. Advances in SLA materials have also led to the development of recyclable and biodegradable resins. Further, SLA's ability to produce complex geometries and lightweight structures results in more efficient designs using less materials and resources.

Autodesk digital design workflows integrate seamlessly with Formlabs’ technology to ease the journey into the world of additive manufacturing.

Bringing your designs to life on a Formlabs SLA printer has never been easier with Autodesk Fusion.

Using the right material for your 3D printed project can make or break a product. Learn what materials you can 3D print.

Here's an engineer’s guide to understanding and implementing additive manufacturing in the production process.

Fusion users can already enable 3D printing of a digital design, and this tutorial explains how to export a Fusion file to an STL/mesh file, the format used on a 3D printing device.

Learn how Hull continues to work in 3D design to continue advancing the useful and innovative tool.

Stereolithography (SLA) is a form of 3D printing. It’s the photochemical process in which a beam of UV light selectively cures an area of liquid resin, hardening it into polymers. In the modern additive manufacturing era, stereolithography describes both the 3D printing process and the device that uses it.

Stereolithography is used to create 3D-printed objects in smaller consumer or prosumer 3D-printing devices, usually with polymer (plastic). A laser or projector generates a beam of light that is aimed at an area of thermoplastic resin, curing it into a harder, polymer-based form. This makes it uniquely suited to creating small, unique objects made of polymers (rubber or plastic).

SLA is used interchangeably with stereolithography, which is the method of shining a focused beam of light on a thermoplastic resin to cure it to a state of hardness.

Although SLS (selective laser sintering) (US Site), another additive manufacturing technology, builds material up one layer at a time like stereolithography/SLA, the raw material in SLS comes in the form of a powdered polymer. A high-powered laser then fuses powder particles together on the print surface, gradually building up the structure.

SLA/stereolithography resin comes in a tank or bottle in liquid form. PLA, or polylactic acid, is a raw 3D-printing material that comes in a spool of solid plastic thread or filament.

The outcomes from SLA resin can be brittle compared to PLA, which is often slightly softer and more flexible. It’s stronger per unit of mass than SLA resin but is not suited to complex or detailed designs.

While researching the various process methods and materials to be used for your parts, review the material data sheets to understand whether that material can work for your intended use. Additional in-house testing may also be needed to confirm the manufacturing method works as needed.

Standard file formats used in stereolithography (SLA) include:

Stereolithography (SLA) printing is an additive manufacturing process where a laser cures and solidifies layers of liquid photopolymer resin to create a 3D object. The laser traces the cross-sectional pattern of the design on the resin's surface, hardening it layer by layer.

Some of the most popular stereolithography (SLA) printers include:

SLA printing offers high precision, smooth surface finishes and the ability to create intricate details, making it ideal for prototyping, medical models and complex components.

Ensuring print quality involves proper calibration of the printer, choosing the right resin for the application and following recommended post-processing procedures.

SLA printing offers high precision, smooth surface finishes and the ability to create intricate details, making it ideal for prototyping, medical models and complex components.