& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Industry 4.0, or the Fourth Industrial Revolution, refers to the automation and data exchange in manufacturing technologies. It integrates modern technologies such as the Internet of Things (IoT), artificial intelligence (AI), big data, cloud computing and cyber-physical systems to create smart factories. Interconnected machines communicate and make decentralised decisions to improve efficiency, reduce waste and increase productivity through real-time data and advanced analytics.

The foundation of Industry 4.0 is building a digital manufacturing ecosystem that enhances flexibility, addresses market demands and enhances innovation in the production process. This integration of physical and digital technologies enables greater precision and customisation in products. It also promotes sustainability by optimising resource use and reducing energy consumption, and aligns manufacturing with environmental goals.

Digital transformation in manufacturing helps manufacturers optimise their operations, improve product quality and reduce downtime. It allows for real-time monitoring and predictive maintenance that enables companies to respond more quickly to market demands, reduce costs and maintain a competitive edge.

Digital transformation also helps enable seamless collaboration and the exchange of data across departments and supply chains to help improve decision-making and streamline processes. Ultimately, digital transformation drives operational excellence to position manufacturers to win in an increasingly digital and interconnected environment.

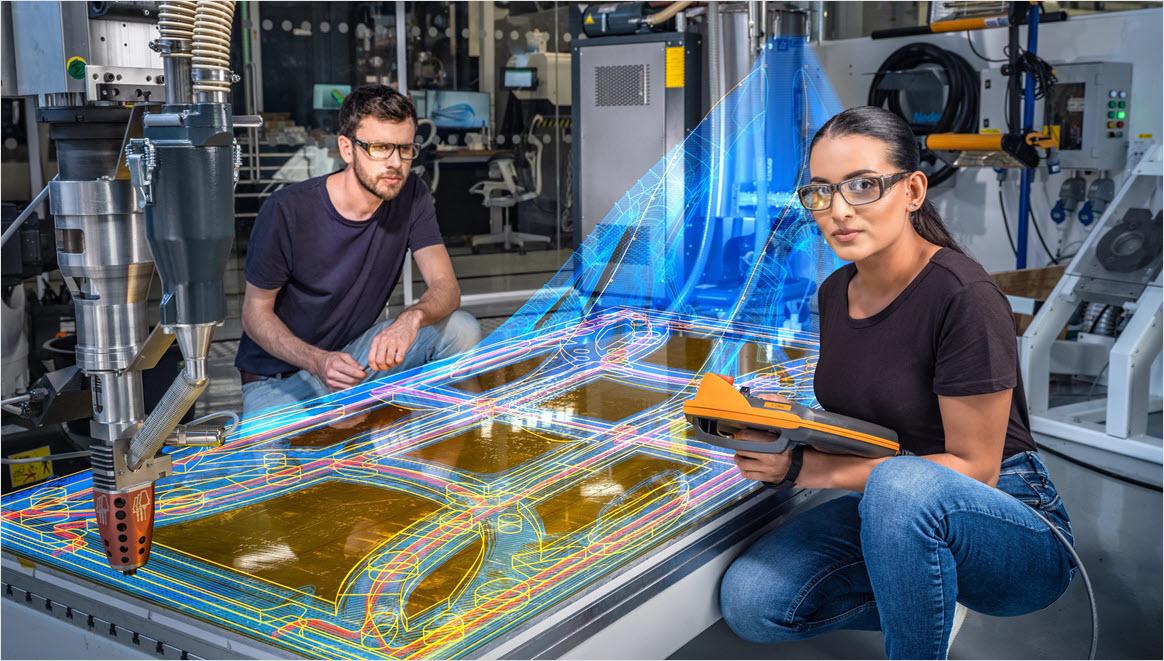

Digital transformation in manufacturing, often referred to as Industry 4.0, involves the application of technologies such as artificial intelligence, automation and robotics, additive technology and human-machine interaction.

By connecting people, processes and data, manufacturers can enhance decision-making, increase productivity and innovation, while ensuring quality control and proper product validation.

Digital transformation in manufacturing can boost throughput by streamlining processes, improving workflows and using technologies like automation and AI for better coordination and faster production.

Advanced analytics and real-time monitoring help in identifying and rectifying issues quickly, leading to better product quality and reduced downtime.

Digital transformation in manufacturing boosts innovation, leading to new products, services and business models. Technologies like IoT help manufacturers create connected products and provide value-added services, resulting in new revenue streams.

Here are some top trends in digital transformation in manufacturing reflecting the sector's commitment to innovation, efficiency and sustainability as it navigates the digital transformation landscape.

Given the competitive landscape, manufacturing businesses plan to significantly increase their investment in software, particularly in areas such as business intelligence and analytics.

The use of digital twins (US site), which are virtual models of physical systems, is set to increase drastically. These digital simulations allow for real-time monitoring and optimisation, enhancing overall efficiency and reducing downtime.

Transforming traditional manufacturing setups into smart factories (US site) is a major trend. The integration of technologies like the IoT and AI automate processes and workflows based on real-time data.

Blockchain technology is expected to address supply chain challenges by providing greater transparency, security and traceability.

Cloud-enabled digital transformation in manufacturing refers to the process of leveraging cloud computing technology to change the ways in which manufacturers operate and deliver value to its customers.

Autodesk Fusion facilitates the cloud-enabled digital transformation journey by connecting data, people and processes. Manufacturers gain access to the tools they need to offer greater value to their customers, employees and stakeholders by breaking down silos and helping organisations work smarter together.

Autodesk Fusion plays a significant role in enabling digital transformation in manufacturing to help manufacturers streamline their processes, innovate faster and stay competitive in the rapidly evolving manufacturing landscape.

Move from concept to production more efficiently with integrated tools. Maintain access to the most recent designs, reduce errors and ensure a unified vision throught the project lifecycle.

From detailed model-based definitions to version control, material specifications and more, Fusion puts data first. Integrating this data with tangible processes like sheet metal fabrication, 3D printing and machining boosts product design to its highest professional standard.

Fusion embeds sustainable design practices into its core, allowing engineers to make informed decisions that consider the environmental impact of their designs.

By integrating information or processes from our partners like Haas Automation, Cadence, Ansys and Send Cut Send, users can benefit from a holistic approach to product development, enabling more efficient workflows and fostering innovation.

Enhancing design, factory and field service processes through digital technologies to increase efficiency and reduce costs.

Innovating products and improving service delivery by leveraging digital tools for faster iteration, better quality and predictive maintenance.

Identifying and pursuing growth through increased factory efficiency, new service models and better management of product complexity.

Using technology to create superior customer experiences and fostering a collaborative culture that embraces new technologies and processes for successful digital transformation.

The introduction of computers in the 1950s marked the beginning of digital transformation in manufacturing. In the 1960s CNC machines were introduced providing automated control of machining tools.

In the 1970s, programmable logic controllers (PLCs) were on the rise, enabling the automation of manufacturing processes. CAD and CAM entered the market and robotics became prevalent on assembly lines.

The concept of CIM emerged and ERP systems were developed to integreate manufacturing processes. The use of the internet also began to connect manufacuring processes. In the 2000s came the rise of IOT, big data analytics and cloud computing.

Industry 4.0 was characterised by the integration of cyber-physical systems, IoT, cloud computing and cognitive computing. It has led to the emergence of smart factories, where machines and systems communicate and cooperate in real time with each other and humans. Additive manufacturing (3D printing) has become more common, enabling rapid prototyping and customised production. Additionally, Augmented Reality (AR) and Virtual Reality (VR) are now used for training, maintenance and design visualisation.

Digital transformation in manufacturing will continue to evolve, driven by technological advancements and the demand for greater efficiency, flexibility and sustainability. Advancements in artificial intelligence (AI) and machine learning (ML) will further optimise manufacturing processes. The adoption of 5G technology will improve connectivity and enable advanced IoT applications. Sustainable manufacutring will become more important, with digital technologies helping to reduce waste and energy consumption. Digital twins will allow for improved simulation, analysis and optimisation of processes.

Many manufacturers depend on outdated legacy systems that are incompatible with modern digital technologies. Transitioning to new, interconnected platforms is often complex and expensive. Achieving seamless integration while maintaining operational continuity necessitates careful planning, significant investment and occasionally a complete infrastructure overhaul.

Adopting digital technologies requires a workforce skilled in data analytics, IoT, AI and cybersecurity. Manufacturers often encounter a skills gap, as their current employees may lack these digital competencies. Investing in training programmes and attracting new talent with the necessary skills is essential but can be challenging and time-consuming.

As manufacturers increasingly rely on digital technologies, they become more vulnerable to cyber threats. Protecting sensitive data, intellectual property, and critical infrastructure from cyberattacks is a major concern. Implementing robust cybersecurity measures, continuously monitoring for threats and ensuring compliance with security standards can be complex and resource-intensive.

Explore digital transformation in the context of manufacturing, including ongoing trends and ways to overcome perceived barriers.

Fusion isn’t just another tool; it’s the cornerstone for any business’ digital transformation or product design journey, regardless of experience level. Learn why Fusion is the only digital transformation manufacturing solution you’ll need.

Learn how cloud-enabled digital transformation tools like Autodesk Fusion are leading the way in making shop floor digitalisation possible.

Supply chain digital transformation refers to the implementation of digital tools, technologies and strategies to improve efficiency and optimise the entire supply chain ecosystem. It ionvolves establishing a vision for how digital applications can improve service, cost, agility and inventory levels, and consistently implementing process and organisational changes that use these technologies to drive operational excellence.

IoT (Internet of Things) digital transformation refers to the use of connected devices that collect and convert data from the physical world into useful information, This results in improved operational efficiency and new opportunities for business innovation. At its foundation, IoT digital transformation is the process of integrating IoT technologies into business models and strategies, resulting in improved performance, productivity and customer-driven innovation, to transform the way businesses operate.

Digital transformation is vital for the manufacturing industry, including:

Cloud-enabled digital transformation enhances data access and collaboration, facilitating real-time information sharing, eliminating data silos and improving analytical capabilities across organisations. This reduces the need for extensive infrastructure maintenance, freeing up IT teams to focus on innovation. Cloud technology also improve customer experiences by enabling advanced technologies such as chatbots, augmented reality, IoT and machine learning.

Digital transformation in manufacturing provides a competitive edge to manufacturers by fundamentally rewiring operational processes, leading to enhanced efficiency and effectiveness. It significantly improves the customer experience by meeting modern consumers' expectations for seamless, quick and digital-first interactions. Through digitalisation, organisations can collect and analyse data more effectively, facilitating data-driven decision-making for more effective strategies and improved business outcomes. Digital transformation enables rapid response to market changes or customer preferences, bolstering resilience. Digital transformation also increases innovation by encouraging organisations to rethink their processes, products and services, thus unlocking new growth opportunities.

Here are five examples of manufacturing digitalisation:

1. Predictive maintenance: Manufacturers use IoT sensors and machine learning algorithms to monitor equipment health in real time. This allows them to predict potential failures, schedule maintenance proactively and minimise unplanned downtime, thereby enhancing operational efficiency and reducing costs.

2. Smart factories: Smart factories utilise interconnected systems, robotics and automation to optimise production processes. For instance, Siemens' Amberg Electronics Plant employs IoT, AI and robotics to create a highly automated and efficient manufacturing environment, resulting in reduced lead times and higher product quality.

3. Additive manufacturing (3D printing): Additive manufacturing enables rapid prototyping and customised production. Companies like General Electric (GE) use 3D printing to produce complex aircraft engine components, allowing for faster design iterations, reduced material waste and the creation of intricate parts that traditional methods cannot achieve.

4. Digital twins: Digital twins are virtual replicas of physical systems that allow manufacturers to simulate, analyse and optimise processes. Rolls-Royce, for example, uses digital twin technology to monitor and optimise the performance of its jet engines, improving maintenance schedules, fuel efficiency and engine lifespan.

5. Supply chain visibility: Digitalisation enhances supply chain visibility and integration. Tesla, for example, uses a digital platform to manage its supply chain, enabling real-time tracking of parts and materials, improving inventory management and ensuring timely delivery of components. This integration helps Tesla respond quickly to changes in demand and streamline production processes.

These examples illustrate how digitalisation can significantly improve efficiency, quality and innovation in the manufacturing sector.

Manufacturing digital transformation involves integrating digital technologies into all aspects of the manufacturing process, fundamentally altering how products are designed, produced and delivered. It encompasses the adoption of advanced technologies such as IoT, AI, machine learning, robotics, cloud computing, big data analytics and digital twins to enhance efficiency, productivity and innovation. Key aspects include process optimisation through automation, real-time data collection and analysis for better decision-making, and the creation of smart factories where machines and systems communicate seamlessly. It also involves accelerating product innovation, improving supply chain integration for better coordination and inventory management, and enhancing customer experience with personalised products and services. Additionally, digital transformation promotes sustainability by reducing waste and optimising energy use. This transformation is crucial for manufacturers to remain competitive, agile and responsive to market changes in an increasingly digital and interconnected world.

The top five digital transformation solutions in manufacturing include:

1. Industrial Internet of Things (IIoT): IIoT involves connecting machines, devices and sensors within the manufacturing environment to collect and analyse real-time data. This connectivity enhances operational efficiency, enables predictive maintenance and improves decision-making by providing valuable insights into the production process.

2. Robotics and automation: The use of advanced robotics and automation technologies streamlines manufacturing processes, increases precision and reduces labour costs. Collaborative robots (cobots) can work alongside humans, enhancing productivity and safety on the factory floor.

3. Artificial intelligence (AI) and machine learning (ML): AI and machine learning algorithms analyse large datasets to optimise production schedules, improve quality control and enable predictive maintenance. These technologies help manufacturers identify patterns and trends, leading to better decision-making and increased efficiency.

4. Digital twin technology: Digital twins are virtual replicas of physical systems that allow manufacturers to simulate, analyse and optimise processes. By creating digital twins of equipment, production lines or entire factories, manufacturers can test scenarios, predict outcomes and make data-driven improvements without disrupting actual operations.

5. Cloud computing and big data analytics: Cloud computing provides scalable storage and processing power, enabling manufacturers to manage and analyse vast amounts of data. Big data analytics tools help uncover insights from this data, driving process optimisation, improving supply chain management and enhancing overall operational efficiency.