& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

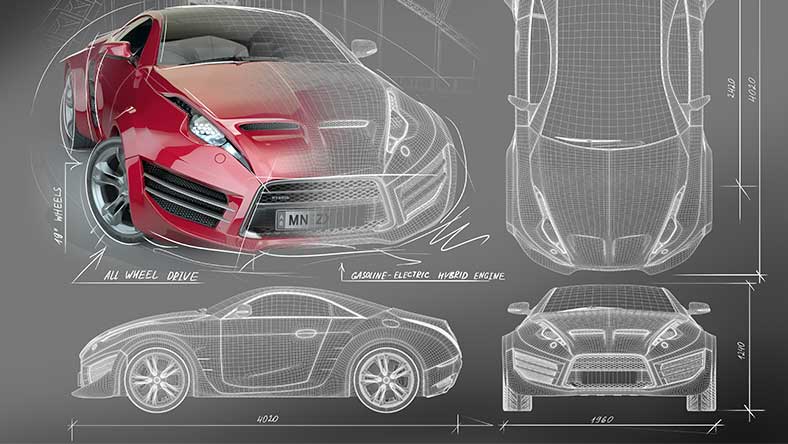

Automotive design combines art and engineering to create vehicles that look good and work well. It starts with conceptual sketches and develops into detailed digital models that engineers use for analysis and production.

Designers consider comfort, appearance, aerodynamics, and how surfaces feel to the touch. This process mixes creative styling with technical precision to ensure vehicles stand out in the market and perform reliably under real conditions.

The field combines industrial design, mechanical engineering, computer-aided engineering (CAE), and simulation. This combination makes automotive design challenging but rewarding, as each design choice affects the vehicle's performance and user experience.

Automotive design begins with concept styling—creating initial ideas on paper or digitally. Designers focus on the overall look and feel of the vehicle. They experiment with shapes and lines until they find a balanced design that represents the brand and the car's character.

Class-A surfacing is crucial at this stage. These are the highly refined, smooth surfaces on exterior body panels and other visible parts. These surfaces determine how the final vehicle looks. Precision ensures reflections, light behaviour, and curves look perfect when working on Class-A surfaces.

Experts consider Autodesk Alias a powerful tool essential for automotive surfacing. It handles complex surfaces and curves, making it ideal for creating attractive and aerodynamic vehicle bodies. With Alias, designers refine sketches into smooth digital models, adjusting curves until the design meets high visual and technical standards. The user-friendly interface helps experienced designers and newcomers efficiently bring their ideas to digital life.

Image courtesy of Misha

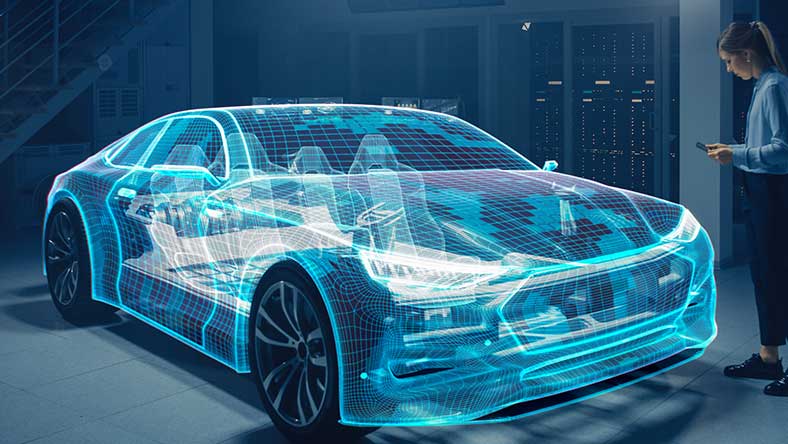

After finalising the exterior design, engineers work on the vehicle's internal structure and mechanical parts. This step requires a detailed 3D mechanical design to ensure all components fit together and work safely under stress.

Software like Autodesk Fusion 360 helps engineers move from artistic concepts to functional models. Fusion combines design, engineering, and manufacturing functions, letting teams create 3D models that look good and perform well. It supports detailed component design, assembly management, and team collaboration.

Designers simulate how different parts interact to find potential problems before physical prototyping. Fusion’s cloud platform allows team members to work together in real time, making the design process more responsive. The software helps engineers quickly improve their designs, ensuring the final product hits all benchmarks.

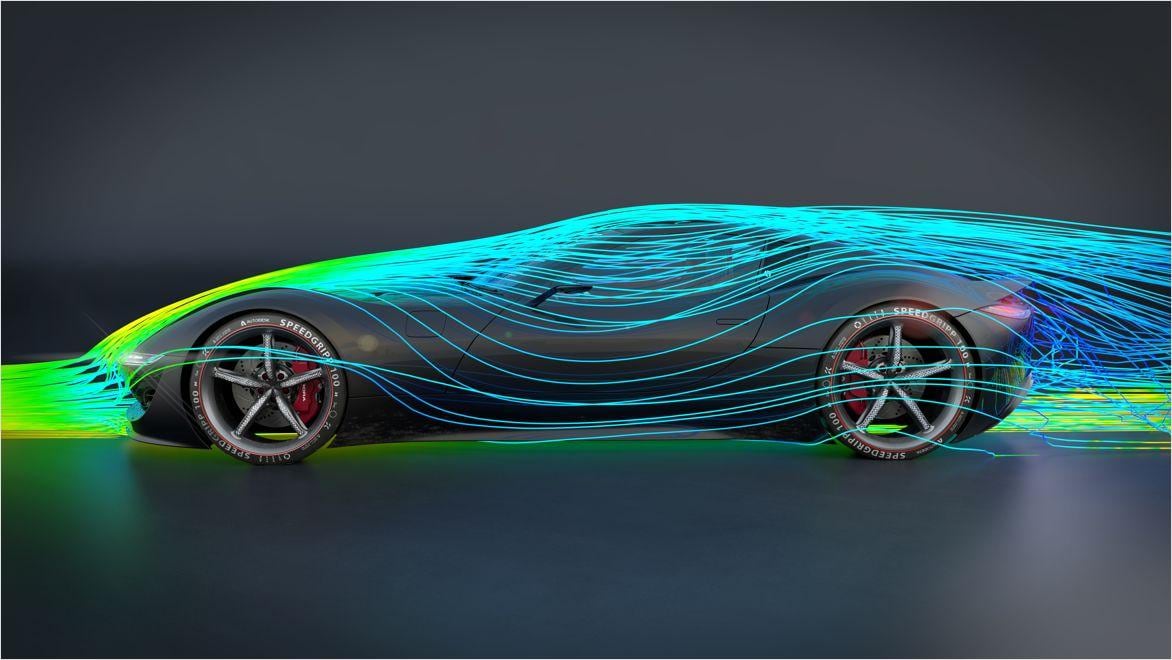

Before building physical prototypes, automotive designs undergo extensive simulation tests. Simulation software assesses vehicle performance under various conditions, such as stress tests, crash simulations, and aerodynamic analyses. This step identifies design flaws and helps optimise components for durability and safety.

Engineers run virtual tests of the vehicle’s performance using CAE tools within platforms such as Autodesk Fusion. These tools analyse forces, deformations, and temperature changes, allowing improvements without the high costs of physical testing. Simulation also shows how vehicles behave under environmental stress. Engineers can test extreme conditions to improve safety features and overall performance. Designers eliminate many potential flaws long before building the physical prototype.

Image courtesy of Just Super

Visualisation bridges the gap between digital models and the real-world experience of the vehicle. This stage creates high-quality renderings and animations that show realistically how the car will look.

VRED is one of Autodesk’s main visualisation tools. Manufacturers and design studios use it to create detailed renderings that accurately simulate lighting, materials, and environmental effects. Teams use these visualisations for internal reviews and customer presentations.

High-quality visualisations help designers evaluate appearance and comfort before production. They also help communicate between designers, stakeholders, and customers, making it easier to gather feedback and make improvements. As automotive design becomes more competitive, realistic visual representations make the difference in project success.

Many emerging companies and startups are entering the automotive market, but high software costs often stand in their way. Autodesk offers flexible licensing options and affordable access models that help startups and educational institutions.

Autodesk's subscription pricing ensures that small teams or individual designers use industry-leading tools without high upfront costs. Educational licenses and trial versions enable aspiring designers to learn and experiment affordably. This accessibility helps new entrants innovate and compete with established companies, creating a more dynamic automotive industry.

Cloud-based collaboration features in platforms like Fusion reduce costs by eliminating the need for extensive in-house hardware. Startups use these tools to streamline design processes and work effectively with remote or distributed teams.

Industrial design software to sketch, concept model, surface, and visualize. Available as Alias Concept, Surface, and AutoStudio.

3D virtual prototyping software for automotive design—available as VRED Design, VRED Professional, and VRED Presenter

For professionals and startups ready to use sophisticated design software, here are some practical tips:

India's automotive industry has become one of the world’s largest. Many manufacturers and design studios use advanced CAD software to improve design workflows. This growth promotes innovation while addressing local market needs.

Local firms increasingly choose Autodesk tools for their features and affordability. The ease of use and comprehensive support help maintain a competitive edge, even for smaller studios and startups.

As the industry evolves, these technologies enable Indian designers to combine traditional craftsmanship with modern engineering efficiency. Aspiring designers in India have access to high-quality training and a global user community, strengthening the local automotive design ecosystem.

Automotive design is evolving with new technologies. Innovations in artificial intelligence, virtual reality, and cloud computing are changing how designers use their tools. We see more automation in simulation and even concept generation, where AI suggests design variations based on data and trends.

Smart collaboration tools enable teams to work seamlessly across continents. As digital twins and integrated simulation models become more common, the boundaries between design and manufacturing continue to blur. The result is faster prototyping, reduced development costs, and vehicles that better meet user needs.

Today’s designers and engineers must stay flexible and adaptable to keep pace with rapid change. By staying current with technology trends and continually developing their skills, automotive professionals can fully leverage the power of modern CAD/CAM software. Whether you're a seasoned automotive designer or a startup founder building your first vehicle, Autodesk tools like Alias, Fusion, and VRED can help you bring your ideas to life and create exceptional vehicles.

Call 000-800-040-2543 (9:30 AM to 5:30 PM India local time) if you need our assistance.

Learn about the future of car design and how virtual reality (VR), generative design, and real-time clay modelling enhance the design process.

Learn about the generative AI tool Kia Global Design and Autodesk Research developed to propose wheel options and how it helped accelerate the design process.

Ian Briggs will walk attendees through the automotive design workflow in this session, from conceptualisation to production.

Alias is a go-to tool for designers and engineers who craft flawless Class-A surfaces, enabling them to produce smooth, precise digital models that define a vehicle's aesthetic appeal.

Fusion bridges the gap between conceptual designs and functional engineering. It helps design detailed 3D models, facilitates simulations, and supports collaboration among team members.

Simulation helps engineers test a vehicle’s performance under various conditions digitally. This process identifies design flaws early, saves time, and minimizes costs associated with physical prototyping.

VRED produces high-quality visualisations that accurately represent the final product. It enhances design reviews, supports customer presentations, and ensures the vehicle meets aesthetic and functional standards.

Autodesk tools work seamlessly across all stages. For example, Alias exports high-quality surfaces to Fusion, while VRED visualises complete models, streamlining the entire design process.

Advancements in AI, cloud computing, and virtual reality drive faster prototyping, smarter simulation, and enhanced collaboration in automotive design, reshaping the entire development process.