& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

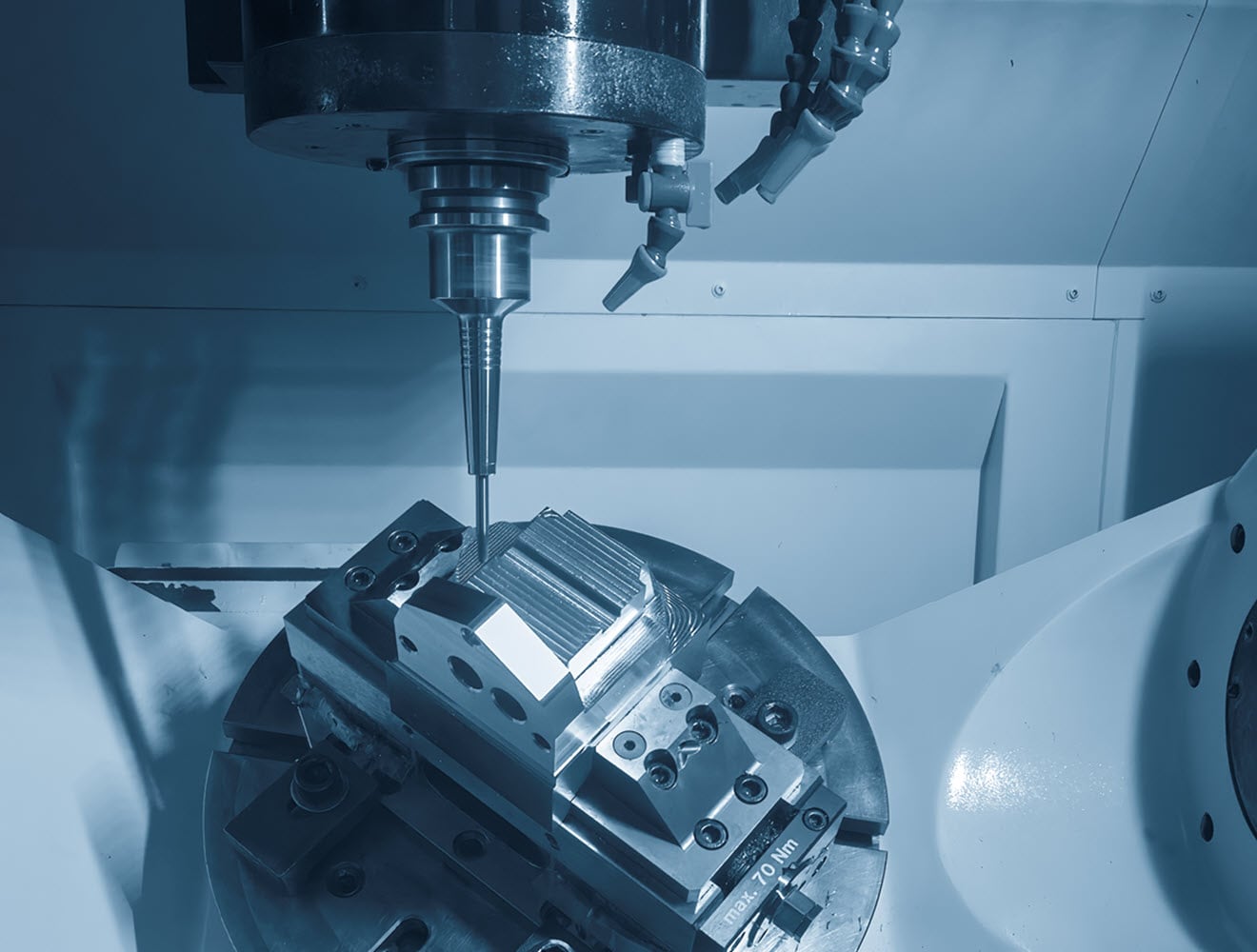

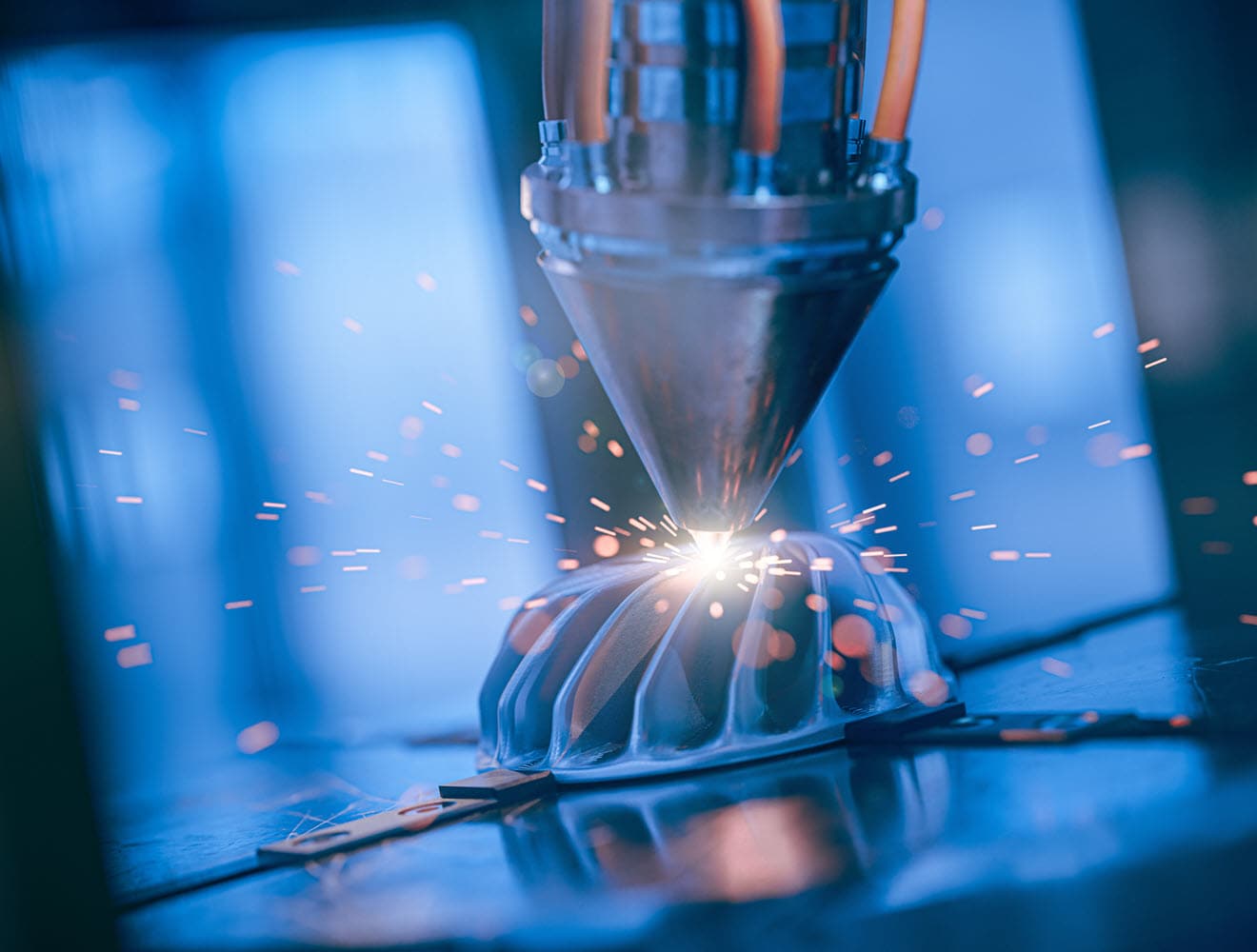

Built on over 40 years of advanced CAM innovation, Fusion is the answer to modern manufacturing needs. Integrated CAD/CAM empowers your business to compete and thrive in today's fast-paced industry.

Seamlessly integrate rapid prototyping, CNC machining, sheet metal fabrication and design for manufacturing (US Site) to streamline workflows and accelerate innovation. Advanced manufacturing capabilities enable your team to transform ideas into reality with unmatched precision and efficiency, enabling growing businesses to enhance their processes and drive sustainable growth.

Start increasing your bottom line and creating higher-quality products to give your business a competitive edge today.

Integrated AI and automation streamline processes, boost efficiency and reduce time-to-market while minimising errors and discrepancies.

Integrated CAD/CAM and real-time data management tools enhance teamwork, align members and accelerate timelines.

Comprehensive machining strategies, including multi-axis machining, probing, deburr and automated hole recognition, enhance precision.

Handle complex machining tasks with precision and efficiency with multi-axis functionality that allows for the intricate and sophisticated designs that would be challenging using traditional methods.

Ensuring parts are machined accurately from multiple angles, multi-axis movements reduce the need for manual intervention and minimise errors.

Optimise the machining process with automated CAM functionality, ensuring accessibility and efficiency for operators of all experience levels. Automate complex tasks, select effective cutting paths, reduce machining time and material waste.

Automated hole recognition streamlines the identification and machining of holes, reducing manual effort and ensuring consistency. Automated deburring removes burrs quickly, improving the aesthetic and functional quality of parts for smoother edges and surfaces.

Quickly and accurately align parts in 3, 4 or 5 axes, reducing setup times and improving machining accuracy with the probing and inspection tools in Fusion. Turn a multi-hour manual process into minutes, with precisely positioned parts for subsequent machining operations, while minimising errors and enhancing overall productivity.

Leverage advanced surface inspection results to calculate optimal part alignment, compensating for misalignment or imprecise fixturing. Use machine-generated inspection data to optimise machining strategies, ensure high precision and reduce the risk of part scrapping due to inaccurate setups.

Quickly generate 2D layouts of sheet metal parts for efficient CNC cutting with associative nesting. Ensure that parts are accurately positioned and prepared for cutting for reduced setup times and less errors.

Advanced nesting algorithms optimise material usage, ensuring that sheet metal is used effectively and waste is minimised, helping to reduce costs and contribute to sustainable manufacturing practices.

Send designs for 3D printing without the need for additional conversion tools, reducing setup times and minimising potential errors. Associative design tools automate the creation of complex geometries and printing support structures, ensuring that even intricate designs are produced accurately and consistently.

Fusion also supports a wide range of materials, allowing users to select the best fit for their specific needs. Ensure that parts are not only functional but also cost-effective and high quality.

Flexible purchasing options to meet your companies current and future needs.

ADVANCED MANUFACTURING CAPABILITIES

Autodesk Fusion for Manufacturing is a cloud integrated CAD, CAD, CAE, PCB and data management platform that includes 3-axis machining, 4 and 5-axis milling and:

Core manufacturing capabilities

Autodesk Fusion is an integrated cloud CAD, CAD, CAE, PCB and data management platform that includes 2 & 3-axis milling and:

Try Autodesk Fusion free for 30-days

Integrations with leading OEMs help streamline common tasks. Learn more about Autodesk partnerships (US Site) with industry leaders.