& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

For over a century, generations of designers, engineers, and technicians have contributed to the exceptional know-how that defines MINO in the design, manufacturing, and commissioning of cutting-edge rolling mills. Autodesk software has supported MINO’s design evolution since the early 2000s and continues to successfully accompany its development today.

Founded in Alessandria in 1840 by the brilliant mind of engineer Giovanni Battista Mino, the company quickly grew in the metal forming machinery sector, initially focusing on machines for rolling silver and precious metals. During the 1960s, MINO evolved into an engineering equipment company, pioneering “coil-to-coil” rolling mills and expanding its market to include the aluminum, steel, and copper sectors. After 180 years in the market, the MINO Group still maintains its main design and manufacturing headquarters in Alessandria, Italy, and is now the leader of an international group that includes five business units across three continents.

The experience and know-how acquired over the years can be summed up in an astonishing figure: since 1970, MINO has supplied and installed over 300 rolling mill plants worldwide for the aluminum, copper, and steel industries.

Among MINO Group’s technological achievements are rolling mills known in the industry as “Foil Mills,” used to produce ultra-thin copper strips (6 microns) for electronic applications (PCBs – Printed Circuit Boards), or ultra-thin aluminum strips (12 microns) for the lithium-ion batteries used in next-generation electric vehicles. Just to give an idea, a human hair has a diameter of about 70 microns. Despite being a lean organization, the Piedmont-based group has, over the years, secured a significant share of the market, competing alongside true global giants in the sector.

Ing. Andrea Coscia, Proposal Engineer, MINO S.p.A.

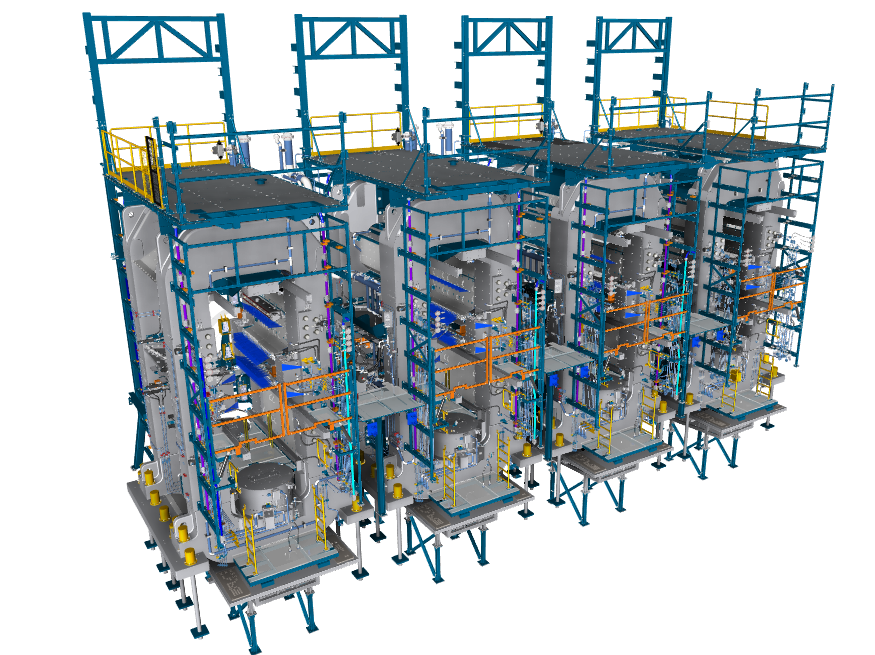

Engineer Andrea Coscia, Proposal Engineer at MINO, explains the key steps involved in completing a plant. It’s a complex set of processes requiring meticulous planning and precise execution. “We offer a full suite of design, manufacturing, and services for flat rolling plants in the three main metal sectors: aluminum, steel, and copper. There is a strong synergy among all MINO departments to carry out highly complex and large-scale projects, often within extremely demanding timelines. Once the design phase is completed, all MINO plants are pre-assembled at our facilities in Alessandria, Vicenza, and Tianjin, allowing us to test them to the highest quality standards before disassembly and shipment to the customer.”

“We adopt this procedure to ensure the quality of every single component and to minimize the installation time at the customer’s site – an approach that sets us apart from other players in the market,” engineer Coscia emphasizes. Once pre-assembly is complete, the plant is shipped to its final destination. It will then take a few more months before the heart of the machine truly starts beating. After commissioning and before final delivery to the customer, the rolling mill must undergo a full series of tests and validation procedures to ensure that performance fully meets the client’s expectations.

“From the moment a rolling mill is commissioned to its start-up, an average of two years passes. It’s a lengthy process, both in terms of design and construction, as well as on-site assembly.” All MINO rolling plants are custom-designed and built to meet the customer’s specific requirements and to achieve increasingly strict and specific benchmarks demanded by the market.

Design has always played a fundamental role at MINO: it must ensure that there are no interferences between different parts and that every system functions correctly according to the expected operating conditions. This underscores how the company has consistently sought out the most advanced solutions on the market to meet the innovation demands that have always defined it.

Engineer Matteo Carrara, Technical Manager at MINO, retraces the recent history of design within the company and explains how, over the years, various Autodesk software tools—combined with a clear vision of the quality standards to be achieved and a highly motivated team—have helped make MINO a front-runner in design innovation, ahead of many competitors.

“Around the early 2000s, MINO was still designing its plants using drafting tables—technical drawing boards, to be clear. The company had already started exploring CAD, but it was only in 2005 that we officially adopted Autodesk software.” “The use of Autodesk products,” Carrara explains, “also stemmed from the need to have a shared platform to interface with other countries and our clients—a requirement that Autodesk could meet, being the market leader.” Just a few years later, in 2008, MINO fully transitioned from 2D to 3D design by choosing Autodesk Inventor to model an entire plant. This decision marked an enormous design effort: MINO’s plants weigh hundreds of tons and include thousands of components.

Looking back, Carrara admits that the hardware and software capabilities of the time were perhaps not yet ready—but that didn’t stop the MINO team or its designers. “The most powerful workstations available at the time were simply not up to the task—the workloads we were assigning them were just too demanding. The only industries managing files of such complexity were animation studios and the aerospace sector, which had already been developing in 3D for years.” “Thanks to a sudden and brilliant insight from our IT department, we turned to gaming workstations, which offered significantly higher performance than standard PCs on the market at the time. It was such a success that we replaced all our existing workstations with gaming ones.” The transition to Autodesk Inventor enabled standardization in both Design and Documentation Management—even for external suppliers working with the MINO Group.

While Autodesk Inventor, together with gaming workstations, ensured high-quality work at MINO, new needs soon emerged. It was 2009. “Once the large assemblies were created, we could no longer manage them effectively,” recalls Carrara. “That’s when a newly launched Autodesk software came to our aid: Autodesk Navisworks.” “For us, Navisworks was a game-changing tool,” adds Engineer Marco Pasotto, Design Manager, who co-leads the technical department at MINO alongside Engineer Carrara.

“Of course, we adopted it in its early stages, but over time—thanks to added features and increasingly powerful releases—we now benefit from full model review, photorealistic renderings, and integrated data. In 2013, we also adopted Autodesk Vault to manage data, revisions, and documentation.” “The software was even installed on the laptops of our engineering team, ensuring quick access to a vast amount of information related to different projects. This allows the group—already in the proposal phase—to meet all the technical requirements of our clients and provide a concrete, detailed visualization of the plant under discussion.”

The first decade of the century was crucial for MINO’s transition to 3D mechanical design—a significant investment in both human and technological resources that paid off greatly, giving the company a competitive edge over others who were only just beginning to explore the world of 3D. “Even though they had more resources than we did—as they were large industrial groups—they couldn’t match us, either in terms of the interface between our sales team and the clients, or in the level of coordination between technical departments and stakeholders,” Pasotto continues.

“For years, we were regarded as a cutting-edge company not only because of the high quality of our products, but above all for our development process—from design through to realization.” “Today, the situation has changed—even our competitors have fully embraced 3D modeling—but when the world came to a standstill during the pandemic, our deep knowledge of 3D proved to be a tremendous advantage. Even during this challenging period, Autodesk Navisworks was a vital tool.

We had just secured a major contract with an important client who wanted to be actively involved in the design phase. With flights suspended, everything had to be done online. Our client was able to follow the development of their production plant step by step each week, through video calls, thanks to Autodesk technology.” For MINO’s design team, Autodesk represents a forward-thinking brand that has consistently invested in innovation. Through strategic acquisitions, it has enhanced its solutions to meet the ever-changing needs of an industry in constant evolution.

To manage thousands of hours of design work, the process must be standardized, monitored, and documented through its various phases and in every decision made. “We need to exchange a lot of data, and we must be certain that everything is saved and that we’re always sharing the most up-to-date information. Autodesk Vault is the tool that ensures our data is organized, shared, and managed through a single, centralized source. However, our database is currently growing at an enormous rate. A project is being studied to duplicate Vault in order to create a digital archive that can function as additional storage.”

“In this context, we are currently shipping a hot tandem rolling mill for aluminum destined for the North American market. This rolling plant is capable of producing 500,000 tons of aluminum annually. Just to give an idea, each of the four main motors installed consumes as much power as it takes to supply electricity to 6,500 homes.” “Without the technological solutions we’ve adopted over the years, we likely wouldn’t be able to remain in the market. The number of interactions and professionals contributing to the real-time design process—both inside and outside the company—is vast.

This level of cooperation is only possible thanks to a technological system that guarantees fast and accurate access to the right information at all times. The ability for multiple people to search for and access this information is an unparalleled advantage,” says Engineer Coscia.

Ing Marco Pasotto, Design Manager, MINO S.p.A.

“In addition to the traditional design and sale of our plants, a large part of our current effort is now driven by the growing demand for services covering the entire lifecycle of a machine—such as after-sales support and spare parts management,” explains Engineer Carrara.

“This need didn’t have a major impact until a few years ago, as customers typically relied on their own in-house technicians for spare parts management.” “Now, more and more customers expect the manufacturer to handle the entire service process. They want a clear, long-term plan from us outlining the spare parts their plant will require in the years to come. This includes both minor service components and what are referred to as ‘capital spares’—parts that should be kept in stock due to long lead times, even if they may only be needed several years after the plant is commissioned.”

“Our challenge is twofold: on one hand, we must handle simple requests that come in via email or phone, and on the other, we need to manage components right from the design phase by identifying which parts will also serve as spares, estimating their lifespan, and compiling associated cost lists.”

“At the moment, we are using Autodesk Vault in a highly creative way to address this new challenge, but we’re also working closely with our trusted reseller to automate the process and—once again—develop a customized technological solution,” Carrara concludes.