Choosing the right material for your 3D printed project can make or break a product. This article covers what objects and materials you can 3D print, key factors for material selection, and future trends in additive manufacturing.

3D printing, also known as additive manufacturing has transformed industries by enabling rapid prototyping, customization, and on-demand production. From aerospace components to medical implants, the technology offers tremendous flexibility. However, one question often arises: what can be 3D printed, and what materials can be 3D printed? The answer depends on the technology, application, and most importantly, the material.

Choosing the right material is very important because it determines strength, durability, cost, and functionality. In this comprehensive guide, we’ll explore:

- What objects can be 3D printed

- What materials can be 3D printed

- A detailed breakdown of materials used in 3D printing

- Key factors for material selection

- Future trends shaping additive manufacturing

What can be 3D printed?

3D printing is can be used across industries for almost anything, including:

- Prototyping: Quickly iterate designs before mass production.

- Functional parts: End-use components for automotive, aerospace, and consumer goods.

- Medical devices: Prosthetics, surgical guides, and dental models.

- Tools and fixtures: Jigs, molds, and assembly aids.

- Art and design: Jewelry, sculptures, and custom décor.

What materials can be 3D printed?

Materials for 3D printing fall into five main categories:

- Plastics: Affordable, versatile, and widely used.

- Metals: High strength for demanding applications.

- Composites: Enhanced properties for specialized needs.

- Ceramics: Heat-resistant and durable.

- Resins: Ideal for high-detail parts.

Each category supports different additive manufacturing processes, such as:

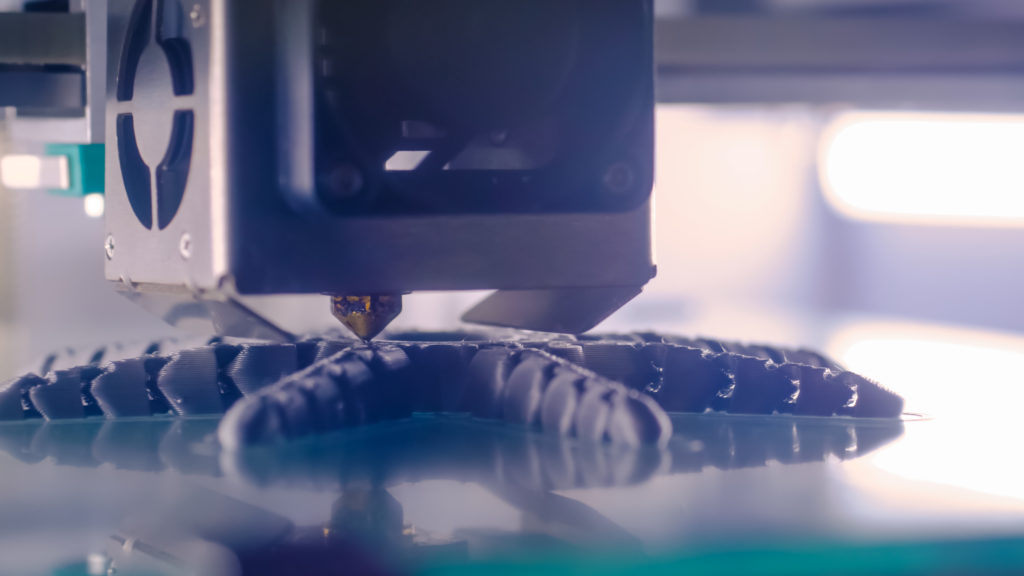

- FDM (Fused Deposition Modeling): Common for plastics.

- SLA (Stereolithography): Uses liquid resins for precision.

- SLS (Selective Laser Sintering): Works with powders like nylon.

- DMLS (Direct Metal Laser Sintering): For metals.

Materials used in 3D printing – A detailed breakdown

1. Plastics

Plastics are the most common 3D printing materials due to their affordability and ease of use.

- PLA (Polylactic Acid):

- Biodegradable and eco-friendly.

- Great for prototypes and decorative items.

- Low heat resistance.

- ABS (Acrylonitrile Butadiene Styrene):

- Strong and impact-resistant.

- Suitable for functional parts.

- Requires heated bed to prevent warping.

- PETG (Polyethylene Terephthalate Glycol):

- Combines strength and flexibility.

- Excellent for mechanical components.

- Good chemical resistance.

- Nylon (Polyamide):

- Durable and wear-resistant.

- Ideal for gears, hinges, and industrial parts.

- Requires controlled environment for printing.

2. Metals

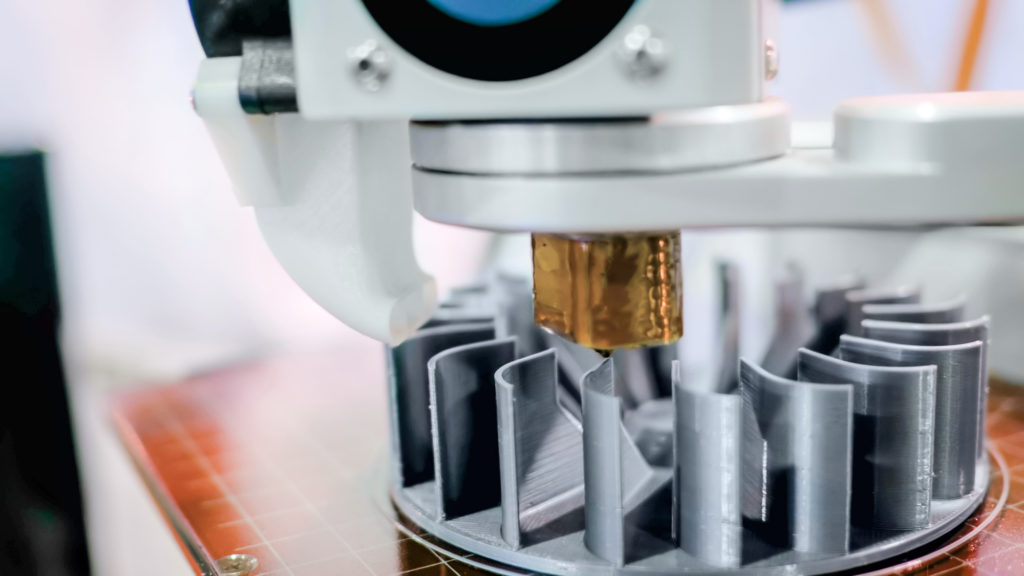

Metal 3D printing enables production of high-strength, lightweight components.

- Aluminum:

- Lightweight and corrosion-resistant.

- Common in aerospace and automotive.

- Titanium:

- Exceptional strength-to-weight ratio.

- Biocompatible for medical implants.

- Stainless steel:

- Tough and versatile.

- Used in tooling and industrial applications.

Metal printing typically uses powder-bed fusion processes like DMLS or EBM (Electron Beam Melting).

3. Composites

Composites combine polymers with reinforcing fibers for superior performance.

- Carbon fiber reinforced polymers:

- High stiffness and strength.

- Perfect for lightweight structural parts.

- Glass-filled nylon:

- Improved rigidity and dimensional stability.

- Used in automotive and industrial components.

4. Ceramics

Ceramic 3D printing is ideal for high-temperature and wear-resistant applications.

- Alumina and Zirconia:

- Excellent thermal resistance.

- Common in electronics and medical devices.

Ceramic parts often require post-processing like sintering for full strength.

5. Resins

Resins are used in SLA and DLP printers for high-detail, smooth-surface parts.

- Standard resins:

- Great for visual models and prototypes.

- Tough resins:

- Impact-resistant for functional prototypes.

- Flexible resins:

- Rubber-like properties for seals and gaskets.

- Dental resins:

- Biocompatible for orthodontic models and surgical guides.

Factors to consider when choosing materials

Selecting the right material depends on:

- Mechanical properties: Strength, flexibility, and durability.

- Thermal resistance: For high-temperature environments.

- Cost: Balancing performance and budget.

- Surface finish: Smoothness for aesthetic or functional needs.

- Sustainability: Recyclable or bio-based options.

Future trends in 3D printing materials

The future of additive manufacturing is exciting, with innovations such as:

- Bio-based polymers: Eco-friendly alternatives to traditional plastics.

- Smart materials: Shape-memory alloys and conductive polymers for electronics.

- Advanced composites: Ultra-light yet strong materials for aerospace and automotive.

- Metal matrix composites: Combining metals with ceramics for extreme performance.

Understanding what can be 3D printed and the materials used in 3D printing is key to unlocking the full potential of additive manufacturing. Whether you’re designing prototypes or producing end-use parts, material selection matters. Tools like Autodesk Fusion to simulate and optimize your designs for the right material choice.

Autodesk Fusion for 3D printing

Fusion is more than a CAD tool—it’s an integrated product development solution that combines design, engineering, and manufacturing in one environment, making it ideal for 3D printing workflows. With features like generative design, you can create optimized, lightweight geometries tailored for additive manufacturing. Its simulation tools allow you to validate strength, thermal performance, and material behavior before printing, reducing costly errors.

Fusion also includes manufacturing-aware design capabilities, helping you plan support structures, optimize part orientation, and ensure printability. Plus, its cloud-based collaboration allows teams to share files, track versions, and work seamlessly across locations. By unifying design and production, Fusion accelerates innovation and ensures your 3D-printed parts meet performance and quality standards.