Boost manufacturing speed, quality, and savings with advanced tooling. Discover how Fusion for Manufacturing unlocks efficiency and superior results for your team.

Elevate your design and manufacturing processes with Autodesk Fusion

The pressure to deliver high-quality parts quickly and cost-effectively has never been greater. Manufacturers are constantly seeking new ways to boost productivity, improve surface finishes, and reduce operational costs. One of the most transformative developments in recent years is the rise of advanced tooling – a suite of cutting tools and strategies that are reshaping how parts are machined. When paired Fusion for Manufacturing can help your team improve efficiency and superior results.

What is advanced tooling?

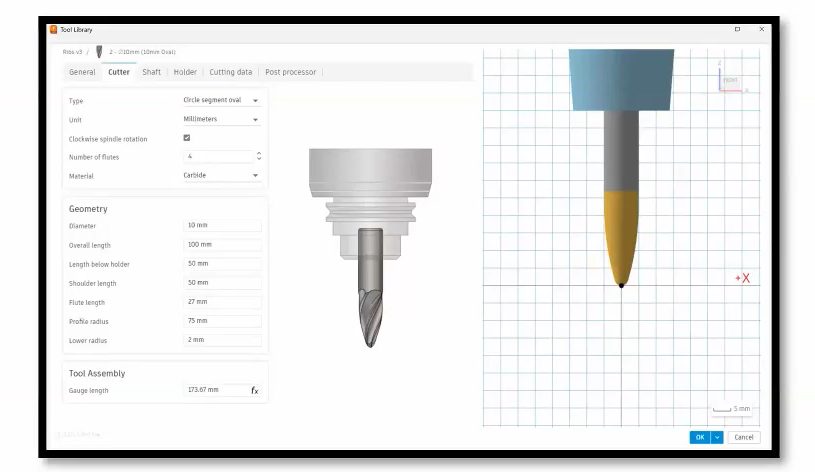

Advanced tooling refers to the use of cutting-edge tool profiles and machining strategies that go beyond the limitations of traditional ball cutters. Specifically, barrel tools, also known as circle segment tools, feature unique geometries – including lens, oval, taper, and barrel varieties. These allow much larger stepovers and step downs, all while maintaining or even improving surface quality.

- Lens variety: This tool has a segment of a radius at the bottom. This allows for twice the stepover compared to a conventional ball cutter. The result is fewer passes and faster machining.

- Oval & taper varieties: These profiles offer greater radii on the side, translating to even larger stepovers and reduced toolpath complexity. Machining becomes quicker and more efficient.

- Barrel variety: Designed for undercut machining and complex part geometries, barrel tools excel where traditional cutters struggle, opening new possibilities for intricate designs.

Benefits of advanced tooling

The benefits of advanced tooling are clear and compelling. With the right toolpath strategies and support for multi-axis milling, barrel tools can deliver up to 10 times the effective stepover compared to traditional methods. This leap in capability translates directly into several key advantages:

- Faster cycle times: Larger stepovers mean fewer passes and less machine movement. The result – part can be completed in a fraction of the time.

- Increased profit margins: Reduced machining time and tool wear lower operational costs, boosting profitability.

- Quicker delivery of finished parts: Shorter cycle times mean faster turnaround, helping manufacturers meet tight deadlines and exceed customer expectations.

As an example, switching from a standard ball cutter to a taper barrel tool can increase stepover from 0.6mm to 6mm, or reducine machine time from over an hour to just minutes.

Advanced tooling requirements

To fully realize the power of advanced tooling, manufacturers need three essential components:

- Multi-axis capability: Advanced tooling often requires precise control over the contact point between the tool and the workpiece. Multi-axis machines enable this control, allowing for optimal engagement and superior results.

- Specialist tooling: Selecting the right barrel tool for each job is crucial. The choice of lens, oval, taper, or barrel profile depends on the part geometry and desired finish.

- Advanced toolpath strategies: Modern CAM software must support sophisticated toolpath generation, enabling precise control over multi-axis movements, optimized contact points, and support for complex geometries. These strategies help maximize machining efficiency and achieving the best possible surface finishes.

Maximizing efficiency with advanced tooling

The impact of advanced tooling on machining efficiency and quality is profound. By utilizing barrel tools such as lens, taper, and oval profiles, manufacturers can:

- Increase step over: Move from fractions of a millimeter to several millimeters, dramatically reducing machining time and the number of toolpaths required.

- Double efficiency on complex surfaces: Optimized tool geometry allows for more effective machining of curved and intricate surfaces, cutting production time in half.

- Enable deeper step downs: Advanced profiles provide improved access to internal features, minimizing the need for additional toolpaths and streamlining the manufacturing process.

The ability to machine more efficiently means your shop can take on more work, deliver higher quality, and remain competitive.

Advanced toolpath control in Fusion for Manufacturing

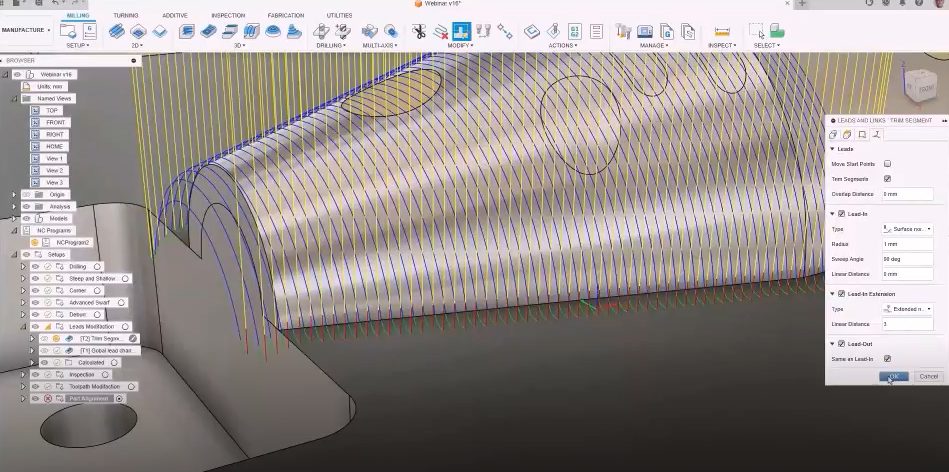

Fusion for Manufacturing gives your team the tools they need to unlock the full potential of advanced tooling. Programmers gain precise control over every aspect of the machining process.

- Surface selection: Users can easily select specific wall and floor surfaces to machine, ensuring targeted material removal and optimal tool engagement.

- Contact point adjustment: Fusion allows for detailed adjustment of contact points on the tool, which is essential for achieving the best cutting conditions and superior surface finishes.

- Flexible toolpath modification: Fusion offers robust options for modifying toolpaths. Users can trim, delete, or fine-tune segments to perfect each operation. This flexibility enables manufacturers to experiment with different strategies and optimize processes for every unique part and scenario.

For instance, machine time for a given part can drop from over an hour to just eight minutes, while toolpath travel distance can be reduced by more than 125 meters. These dramatic improvements are made possible by the combination of advanced tooling and Fusion’s intelligent toolpath control.

Transform your shop today

By embracing innovative tool profiles and intelligent CAM workflows, manufacturers can achieve unprecedented speed, quality, and cost-effectiveness. Fusion for Manufacturing provides the tools you need to realize these benefits, making it easier than ever to optimize your processes and deliver superior results.