Additive manufacturing delivers value through prototyping, functional testing, customization, lightweighting, and digital inventory. These applications need fast iteration and strong links between design and production. Fusion supports this need by integrating additive preparation with CAD and engineering workflows so that teams improve consistency, speed, and manufacturability.

Elevate your design and manufacturing processes with Autodesk Fusion

Additive manufacturing has moved well beyond its early application as a simple visualization aid. With advances in technology, additive manufacturing is now a production-ready process that can influence how engineers approach product design.

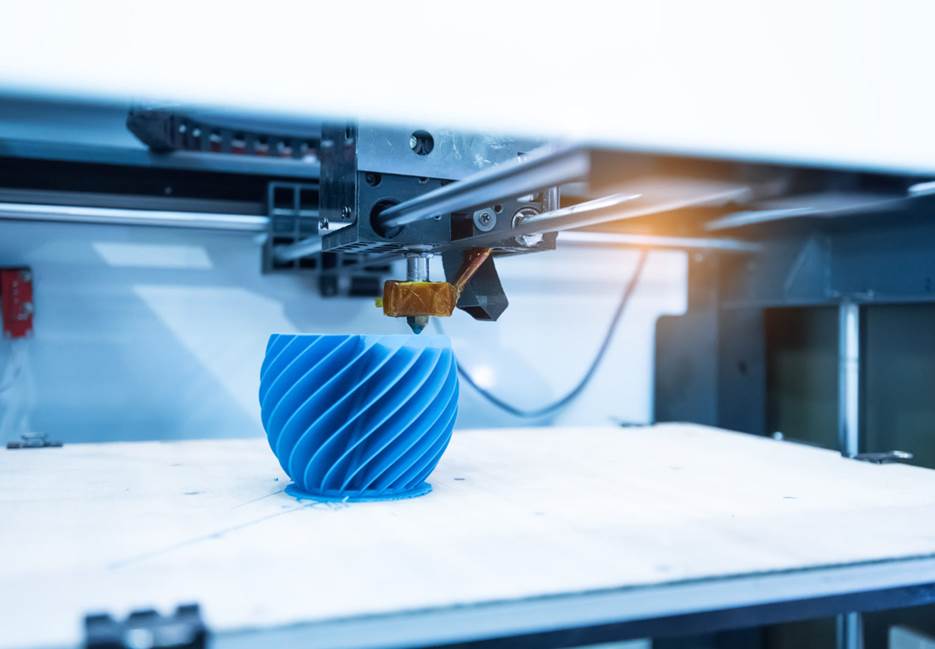

Commonly known as 3D printing, the technology empowers teams to bypass traditional constraints, create complex geometries, and realize supply chain efficiencies that were previously impossible. Regardless of industry, teams now rely on additive manufacturing to compress development cycles, reduce tooling costs, and explore design options.

This piece discusses the top five applications of additive manufacturing and how Autodesk Fusion supports them with an integrated design-and-manufacturing platform.

1. Rapid prototyping

One of the most immediate and impactful applications of additive manufacturing is rapid prototyping. This process allows engineering teams to turn digital designs into physical objects in a matter of hours rather than weeks. By quickly producing tangible models, designers can validate form, fit, and function early in the development cycle. As a result, they significantly reduce the risk of errors later in production. Such an iterative approach also encourages more experimentation, as the cost penalty for a failed design concept is lower than with traditional machining or molding. As a result, product cycles are shortened, and the final output is often more refined and robust due to the rigorous physical testing enabled by accessible prototypes.

2. Jigs, Fixtures, and Tooling

Beyond prototyping, manufacturers are now using additive manufacturing to create jigs, fixtures, and tooling. Traditionally, creating custom tools to aid in assembly or machining was a time-consuming and expensive endeavor, often requiring its own dedicated supply chain. Additive manufacturing allows engineers to print custom tooling on demand, tailored specifically to the ergonomic needs of the worker or the geometry of a workpiece. This application reduces lead times for tooling acquisition and lowers the barrier to entry for low-volume production runs where expensive metal tooling could be cost-prohibitive.

3. Customization

Additive manufacturing has unlocked new levels of customization for designers. In the medical sector, the technology enables engineers to economically produce unique, patient-specific devices—such as orthotics and surgical guides—without requiring a separate mold for each unit. In consumer products, like eyewear and footwear, additive manufacturing lets designers tailor goods to individual biometric data. The ability to produce thousands of unique items in a single print run fundamentally alters the economics of customization, moving it from a luxury service to a scalable industrial process.

4. Lightweighting

In industries where performance is the top priority, like aerospace and automotive, additive manufacturing is useful for lightweighting designs. Additive processes help teams manufacture lattice structures and topologically optimized shapes that reduce mass without compromising structural integrity. These geometries are often impossible to manufacture with subtractive methods like CNC machining. By reducing weight, designers can reduce a product’s operational costs and environmental impact.

5. Digital inventory

In addition, additive manufacturing is reshaping logistics through the concept of digital inventory and spare parts management. Instead of warehousing physical parts for decades to service legacy equipment, companies can keep design files and print replacement parts on demand. This approach drastically reduces inventory costs and warehousing space requirements. It also builds resilience into the supply chain, as parts can be produced locally near the point of need rather than shipped globally—thereby mitigating the risks of shipping delays and logistics disruptions.

Unlocking additive potential with Autodesk Fusion

Autodesk Fusion addresses the complexities of diverse applications by providing a unified environment that marries design and manufacturing.

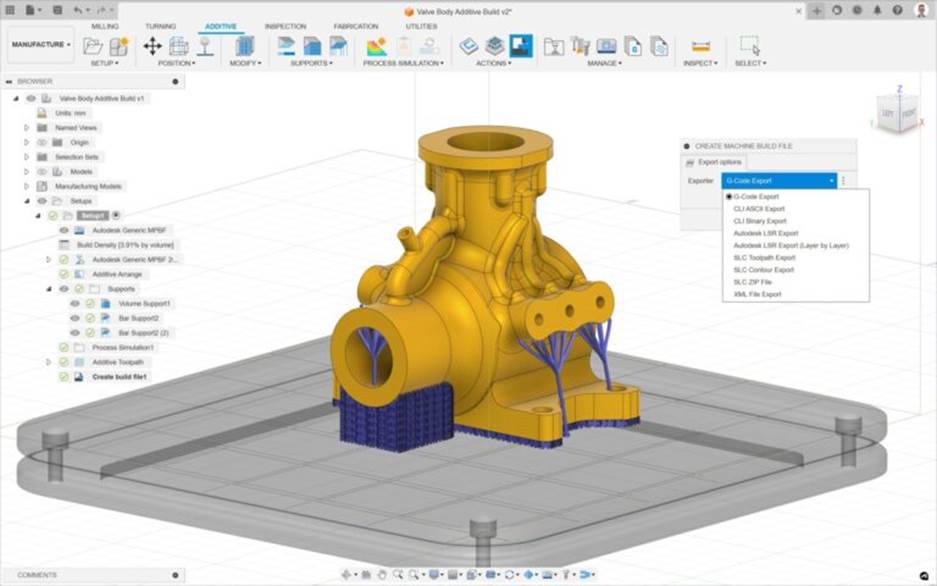

Rather than requiring designers to export files to disparate software for print preparation, Fusion integrates CAD, CAM, and CAE into a single platform. The most immediate benefit of this approach is data integrity. For example, changes to the design model are automatically reflected in the manufacturing workspace, eliminating the need for constant file exports and reducing the risk of version-control errors. The software’s 3D print preparation module allows users to define their specific machine, orient parts for optimal build quality, and generate necessary support structures within the same interface used for design.

Fusion for Design includes powerful generative design capabilities to support the advanced geometry required for lightweighting. Engineers can input design goals, constraints, and material parameters, and the software inevitably generates multiple high-performance design alternatives. These organic, optimized shapes are often specifically optimized for additive manufacturing processes, meaning that the resulting components are guaranteed manufacturable. With a direct link between algorithmic design and additive constraints, engineers can fully harness the design freedom offered by 3D printing and push the boundaries of what is structurally possible.

Further, Fusion integrates with a wide range of additive hardware, allowing the software to drive the specific additive technology available to the user. Whether the workflow involves fused filament fabrication (FFF) or metal powder bed fusion, Fusion can connect with a library of 3D printers from top industry manufacturers. With broad compatibility, Fusion helps designers manage the entire process without leaving the ecosystem. Also, by consolidating these tools, Fusion enables engineers to move fluidly from a digital inventory file to a physical spare part while maintaining form, fit, and functionality, regardless of the additive substance used.

Supporting the future of manufacturing

The strongest applications of additive manufacturing share a common need for alignment between design and production intent. Regardless of application, all additive manufacturing workflows can benefit from systems that minimize friction between modeling and manufacturing. Fusion offers the best of both worlds by bringing additive modeling directly into the main design environment. In this way, engineers can move from idea to printed part with greater clarity and control.