& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

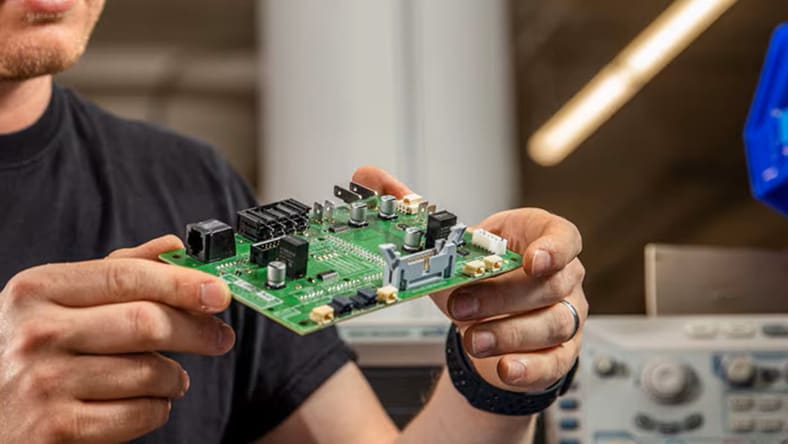

Electronics and consumer product design combine hardware and software concepts to bring ideas to life as real products. It involves designing electronic circuits (US Site), printed circuit boards (PCBs) (US Site), and the outer cases for devices such as mobile phones, appliances, wearables, and IoT gadgets. The process combines electrical engineering, mechanical design, ergonomics, and aesthetics. Simply put, it’s about creating physical products people use every day.

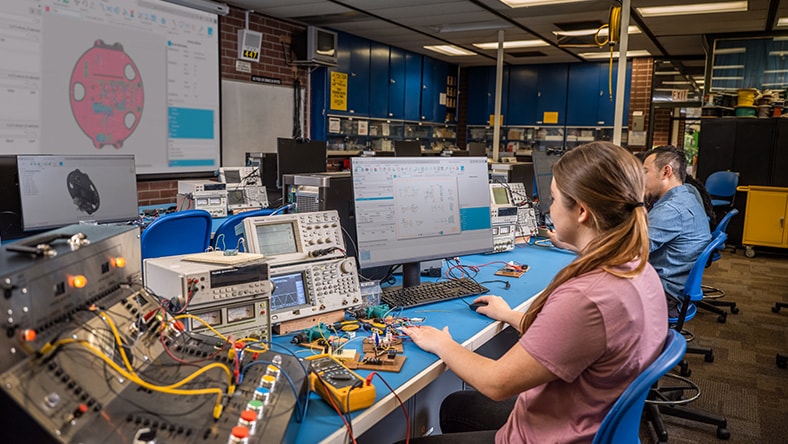

Engineers and designers use computer-aided design (CAD) tools to draw and test their ideas before making physical prototypes. This step-by-step process reduces errors, shortens development time, and improves product performance. As electronics and consumer devices become more complex, clear design processes strike a balance between functionality and appearance.

Recent advances in artificial intelligence (AI) (US Site) have opened up new possibilities for designers. AI now offers practical tools that enhance and accelerate the design process. In India, where electronics manufacturing is growing with support from initiatives like the Production-Linked Incentive (PLI) scheme, AI-powered design tools provide an essential advantage.

AI has significantly changed PCB design. Traditional PCB design requires detailed manual routing and careful layout planning. Mistakes can be expensive, causing delays and higher production costs. AI-assisted tools analyse circuit schematics and automatically suggest the best routing paths that reduce interference and maintain signal quality. This process reduces human error and speeds up the prototyping process, allowing teams to test designs and make continuous improvements.

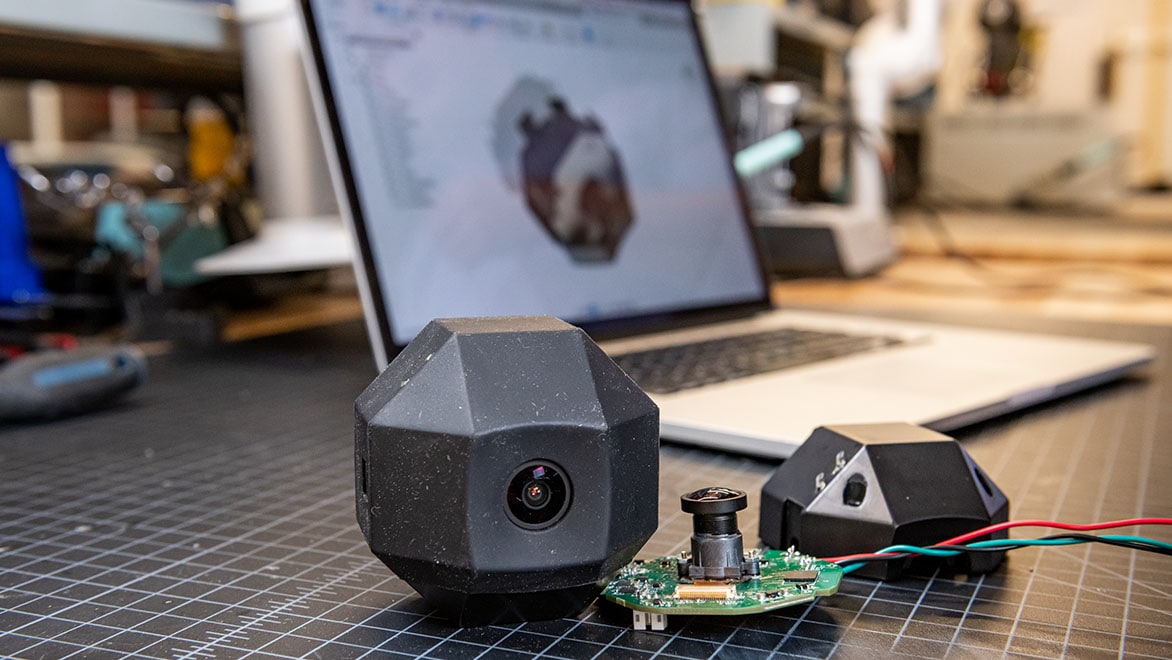

Generative design (US Site) is another key feature of modern CAD tools. Instead of manually adjusting every curve or edge on a product case, generative design allows software to explore a diverse range of configurations. Designers set the basic requirements and limits, such as weight, strength, material constraints, and appearance, and the software creates multiple optimized versions.

Designers in consumer electronics use generative design to identify stress points and improve airflow in space-constrained, heat-sensitive environments. Autodesk Fusion stands out by combining different types of simulations. It allows engineers to run tests and optimize enclosures for everything from durability during drop tests to heat management in small devices. This integrated approach delivers better-performing products in less time.

The feedback loop in electronics design has become much shorter. Modern CAD tools enable advanced simulation and work with data analysis tools to refine designs based on real-world usage. For example, sensors in a smart appliance or wearable device can continuously provide data on performance and user interaction. This data feeds into AI algorithms that help predict stress points, inefficiencies, or potential failures in the design.

Engineers can quickly update their designs using this feedback. Rapid prototyping tools combined with simulations eliminate guesswork. Companies can launch products, gather user data, and make quick improvements. This repeated process ensures that the final product works well and is user-friendly.

India’s electronics sector benefits from strong market demand and supportive government initiatives. The Production-Linked Incentive (PLI) scheme has increased investment in local manufacturing. With talented professionals and competitive manufacturing, India is changing from an electronics market to a design and production center.

Large companies like Samsung, with significant R&D investments, work alongside new startups. These startups develop smart home devices and IoT (Internet of Things) applications that enhance daily life. In this environment, advanced AI-powered design tools create a competitive setting where innovation thrives.

AI-enhanced design platforms are essential parts of the innovation process. They improve workflows by automating routine tasks and providing insights that inform design decisions. These systems work well with traditional CAD practices, allowing even small teams to create products that meet high-performance and regulatory standards.

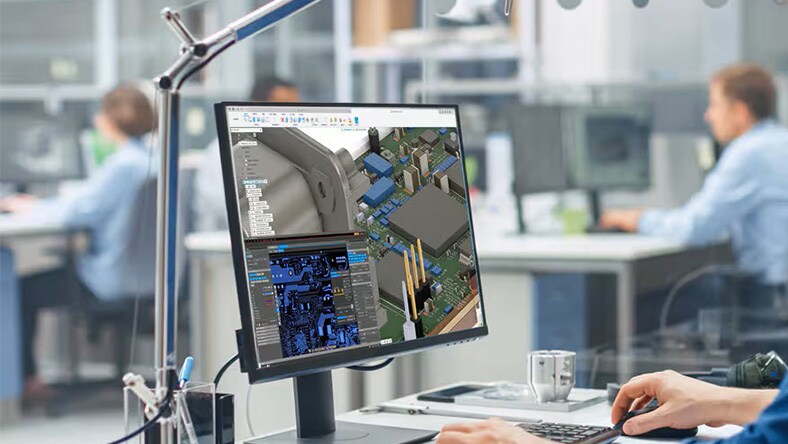

Integrating AI with existing design systems can be a challenging task. Many companies face technical and operational difficulties during initial adoption. However, leading tools from Autodesk make this transition easier by offering user-friendly interfaces and extensive support documentation. For example, integrating ECAD and MCAD (US Site) in Fusion reduces problems and allows teams to adapt smoothly.

The technology landscape changes constantly, and design teams must continually update their skills. Continuous learning remains essential, and many software providers offer online tutorials, webinars, and certification programs. This educational support helps engineers stay up to date with both the theory of AI and the practical application of new tools.

While AI has many advantages, real-world product development requires striking a balance between innovation and manufacturing feasibility. Designers must consider material costs, production timelines, and safety standards. AI-powered tools help by providing accurate simulations that reflect manufacturing constraints. This balance ensures that designs are innovative and viable in a competitive market.

Engineers can no longer rely only on manual methods in their design process. Instead, AI and modern CAD tools offer powerful capabilities, from optimizing PCB layouts (US Site) to simulating the physical integrity of product enclosures. Adopting these tools provides a competitive advantage and encourages continuous learning.

Integrating AI-powered design processes into your workflow positions you well for future challenges. The benefits of improved accuracy, reduced time-to-market, and efficient collaborative workflows create opportunities for more innovation in electronics product development.

Integrating Autodesk solutions such as Fusion and Fusion Design Extension into workflows highlights the shift toward data-driven, efficient, and reliable design processes. As the industry advances, keeping up with these tools will help designers create products that meet technical requirements and consumer needs.

Ready to experience efficiency and precision in design processes using intuitive and comprehensive consumer electronics design software?

Create your products using the latest 3D product design and manufacturing software, including Inventor, AutoCAD, and Fusion, all in one package.

Use Fusion to design plastic housings, create PCBs, spot potential injection molding problems, and see how your electronic parts come together.

Learn about making breakthrough consumer products with Autodesk Fusion. The software combines electrical (ECAD) and mechanical (MCAD) design, making it easier to create innovative electronic products.

AI assists in auto-routing, error-checking, and optimizing layout efficiency, reducing design errors, and speeding up the process.

Generative design uses algorithms to offer multiple optimized design alternatives based on set constraints such as strength, weight, and materials.

Autodesk Fusion is used for 3D modelling, simulation, manufacturing, and collaboration across mechanical engineering and product design.

The PLI scheme supports local manufacturing and innovation, encouraging companies to invest in advanced design tools and technologies.

Yes. These tools reduce time and capital requirements, enabling even lean teams to develop competitive products.

Modern CAD tools use automation and simulation to reduce lengthy manual iterations, which leads to faster transitions from design to production.

It combines electronic and mechanical design processes into one seamless workflow, reducing errors and improving collaboration.