& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

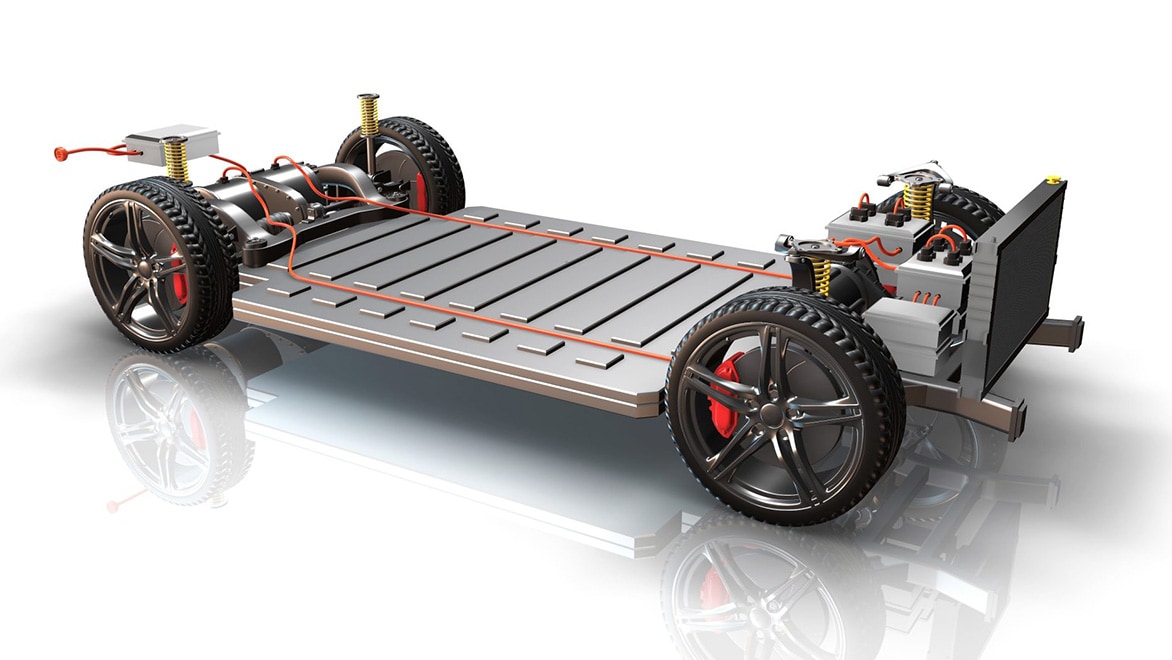

Electric vehicles (EVs) run on electricity instead of gasoline or diesel. They use electric motors powered by rechargeable battery packs. Unlike traditional internal combustion engine (ICE) vehicles, EVs produce no exhaust emissions, are quieter, more efficient, and need less maintenance.

As the world focuses on reducing carbon emissions, EVs are helping India move toward cleaner transportation.

India has set an ambitious target — make 30% of all new vehicle sales electric by 2030. Government policies are driving this shift, with the FAME scheme offering key subsidies that lower costs and boost adoption. Meanwhile, local startups are innovating rapidly, accelerating the expansion of India’s EV ecosystem.

Companies such as Ather Energy and Ola Electric show what's possible with the right tools. Indian EV startups increasingly use digital design solutions that combine electronic and mechanical design (ECAD and MCAD) in one workflow. Autodesk Fusion accessible pricing and powerful simulation capabilities make it a smart solution for comprehensive EV design.

EVs are better for the environment and have little to no emissions. They're cheaper to operate than fuel-powered vehicles and need less maintenance due to fewer moving parts. When powered by renewable energy like solar (US Site) or wind, EVs become an even cleaner and more sustainable transportation choice.

Driving an EV is a smooth, quiet experience. They accelerate quickly and have modern features like regenerative braking. You can charge them at home, and many governments offer incentives to encourage wide adoption.

In 2024, India reduced EV import duties to encourage local manufacturing. With a focus on achieving energy transition and net-zero targets by 2070, the government launched initiatives such as the Faster Adoption of Manufacturing of Electric Vehicles Scheme – II (FAME – II) and the Production Linked Incentive Scheme (PLI) to support adoption.

Optimise part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection moulding and more.

EV startups in India often have teams in different locations — designers in Bangalore, manufacturers in Pune, investors in Mumbai. Cloud platforms such as Fusion allow real-time collaboration and version control across devices and locations, speeding up development and reducing errors.

Many automotive engineers use advanced design tools for next-generation vehicles:

PIX moving uses Fusion generative design to create customised vehicles with faster development times.

Simple energy used digital 3D modelling to speed up the design of their Made-in-India One electric scooter, allowing for faster design changes and better vendor collaboration.

Rokion’s electric mining vehicles integrate ECAD and MCAD for optimal performance, showcasing tightly integrated battery packs and motors designed from scratch.

Designing an EV involves multiple disciplines and high stakes. With the right software, teams can reduce weight, optimise battery placement, integrate electronics, and test thermal systems before building physical parts.

Fusion offers an integrated workspace for mechanical (US Site) and electronic design, cloud collaboration (US Site), optimisation, and simulation (US Site), helping teams build safer, more efficient vehicles.

Click here to buy online or call 000-800-040-2543 (9:30 AM to 5:30 PM India local time) if you need our assistance.

Battery placement and heat management are critical for safety, efficiency, and performance.

Use generative design to find material-efficient shapes that meet structural requirements.

Yes, Fusion has built-in tools for testing cooling strategies.

Fusion cloud platform allows real-time co-editing, version tracking, and remote access from any location.

You can create virtual models, run simulations, and prepare manufacturing files on one platform.

Simulations provide good approximations that reduce the number of physical prototypes needed, saving time and cost.