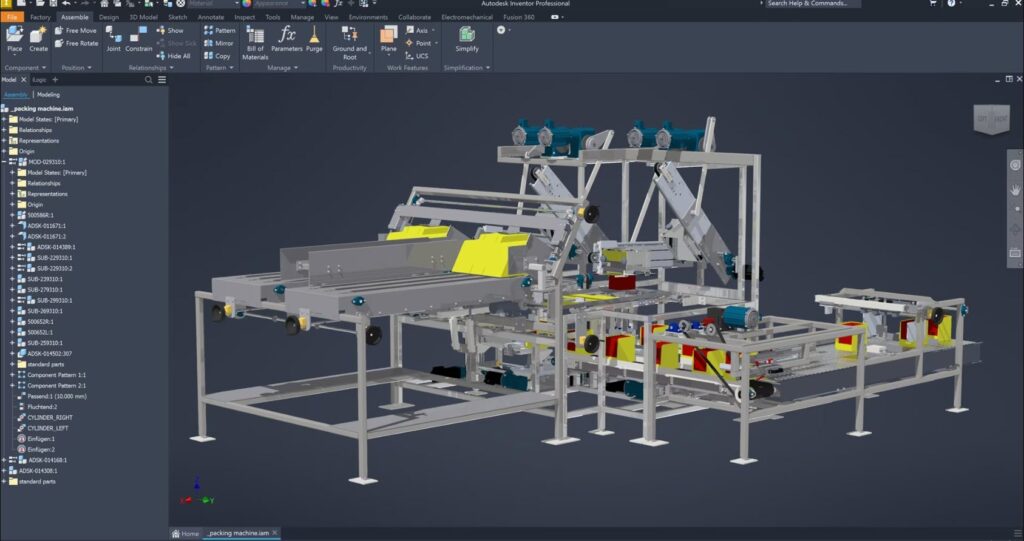

Engineering bottlenecks slow industrial machinery manufacturers and increase costs. Learn how the Autodesk Product Design and Manufacturing Collections streamlines workflows, reduce cycle times, and accelerate product delivery.

Autodesk Product Design & Manufacturing Collection

Solve interesting problems efficiently with the ultimate set of engineering apps.

Learn MoreIndustrial machinery (IM) manufacturers are constantly faced with high expectations for custom configurations and faster delivery, all while product complexity continue to rise. Engineering teams often struggle with legacy processes, disconnected systems, and unpredictable workloads. In this environment, engineering bottlenecks become exponentially expensive.

Whether caused by manual design practices, poor data visibility, or slow iteration cycles, these delays cascade across the entire product lifecycle. A bottleneck in engineering quickly becomes a bottleneck in sales, production, and customer delivery. Fortunately, the Autodesk Product Design & Manufacturing Collection is helping industrial machinery manufacturers break through these constraints.

The hidden costs of engineering bottlenecks

Engineering bottlenecks are rarely isolated events. They tend to form a chain reaction that affects multiple departments. Here are the biggest cost drivers:

- Slow design iteration: Many IM teams still rely on repetitive, manual workflows. When every design change requires redrawing, updating assemblies, and regenerating drawings, engineers spend more time manage complexity than solving real problems.

- Rework and quality issues: Bottlenecks often lead to rushed deliverables, allowing costly drawing or model errors to slip into manufacturing. A single machining mistake or misaligned component can trigger scrap, emergency rework, or even warranty risk.

- Siloed teams and disconnected data: When engineering data is scattered across systems or buried in email attachments, teams waste time hunting for the right file or the latest version.

- Delayed time to market: Every day a product launch is delayed, IM companies miss revenue opportunities. Slower cycles also weaken competitiveness against faster, more digitally mature rivals.

The good news? These issues are solvable with the right digital foundation.

How PDMC helps industrial machinery teams breakthrough engineering bottlenecks

The Autodesk Product Design & Manufacturing Collection was designed precisely to address the pain points IM manufacturers face. Here’s how:

Parametric and automation-driven design speeds up iteration

Parametric modeling in Inventor helps engineers handle product complexity. Instead of manually rebuilding geometry after each change, engineers update a few parameters and let Inventor regenerate the model.

But the real accelerator is automation—specifically, iLogic within Inventor and the advanced automation capabilities included in PDMC.

These tools allow teams to:

- Build rules that automatically configure components

- Create product configurators for sales or engineering

- Standardize repetitive design tasks

- Automatically generate drawings, parts lists, and variants

What previously took hours of engineer time can be completed in minutes – consistently and error-free.

Improved collaboration and visibility across teams

A single engineering assembly may contain thousands of parts, and coordination between mechanical, electrical, controls, and manufacturing teams is essential. PDMC solves this by integrating design, simulation, collaboration, and visualization tools under one umbrella.

Tools within PDMC, such as Autodesk Vault, Factory Design Utilities, and shared data workflows ensure that:

- Teams always work from the source of truth

- Version control is automated

- Stakeholders collaborate more easily

- Design changes flow faster across departments

This eliminates the versioning confusion, delays, and reduces miscommunication.

Faster validation with integrated simulation and analysis

Physical testing is expensive and time-consuming. With Inventor Nastran, generative design, and simulation tools inside PDMC, engineers can validate performance early and often.

Validating earlier means fewer late-stage changes, fewer prototypes, and faster overall cycles.

Connected workflows to Autodesk Fusion for next-generation efficiency

A key advantage of PDMC is its strong tie to Fusion, Autodesk’s cloud platform for design and manufacturing. Together, they enable Industrial Machinery teams to extend their Inventor workflows into the cloud, unlocking collaboration beyond the desktop, scalable automation, and advanced simulation capabilities that complement traditional design processes.

Fusion fits naturally alongside core PDMC workflows, building on familiar tools such as Vault for data management, AnyCAD for working across multiple CAD systems, and iLogic or APIs for custom automation. By extending these workflows with PCB design, integrated CAM, high-quality rendering, and connections to PLM systems, teams can move data between environments using the right tools for the job no matter the product.

End-to-end value for the entire business, not just engineering

The time savings from taking full advantage of the Product Design & Manufacturing Collection accumulate across the organization:

- Sales responds faster with configurable proposals

- Engineering spends less time on repetitive work

- Manufacturing receives accurate, complete, and up-to-date models

- Leadership gets faster delivery cycles and higher throughput

When engineering becomes more agile, the entire business becomes more competitive.

Engineering bottlenecks are costly, frustrating, and ultimately lead to competitive disadvantages. By fully realizing the power of the Autodesk Product Design & Manufacturing Collection, teams can finally eliminate the constraints that slow them down. Get started today.