Exemplary Projects from Today's Construction Industry

As the world’s population grows, demand for new buildings is increasing, especially in cities. At the same time, designers and engineers continue to push the creative limits of what’s possible for the built environment. How can we create structures that are increasingly sophisticated and functional while accelerating schedules and reducing waste? The following projects demonstrate new approaches to construction that enable us to build more and build better with less.

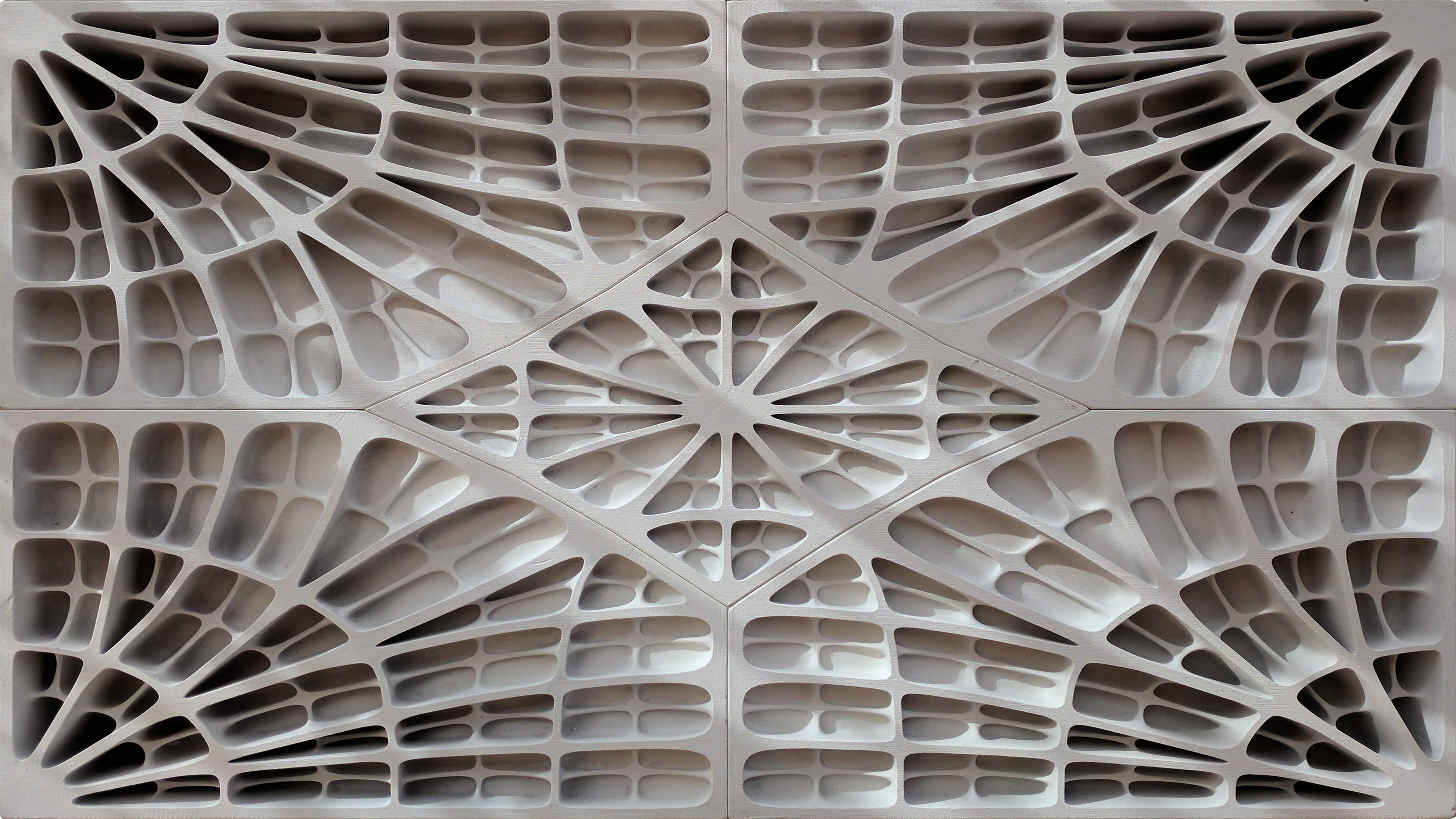

A Materially Efficient Concrete Flooring System

Located in Dübendorf, Switzerland, the NEST (Next Evolution Sustainable Building Technologies) is a multi-unit building that’s always under construction. It serves as a laboratory in which teams from the Block Research Group of ETH Zürich can explore innovative ways to build better.

One part of NEST is the HiLo Unit, which is focused on finding ways to combine lightweight concrete structures and novel digital fabrication methods with high impact, low energy building systems (thus, HiLo). A key innovation of HiLo is the materially efficient flooring system. The rib-stiffened concrete panels are doubly curved shells that use funicular geometries to provide the strength of a traditional concrete slab with a dramatic reduction in the amount of concrete needed—up to 70%, depending on the floor span. The team is currently exploring different methods of fabricating these funicular floors to reduce waste, including 3D printing and a new technique—casting on a custom-knit fabric for the insertion of capillary tubes later.

A System for Automated Construction

Most structures take months to build. Many take years or even decades. Construction software pioneers at StrucSoft and fabrication innovators at Howick have collaborated to create an integrated system that enables the manufacturing and assembly of a structure in just a few days.

Metal sheets go into the roll-forming machine and components emerge ready for assembly. Customization is easy and little waste is created. Productivity gains of as much as 500% are possible using detailed BIM LOD 400 drawings.

This is what the design-to-make workflow in construction can be: precise, efficient, and driven by data.

Tianjin Chow Tai Fook Financial Center – BIM for Better Building

Standing 530 meters tall and 103 stories high, the Chow Tai Fook Financial Center is an impressive addition to the city of Tianjin, and not only because of its size. The project, a winner of a 2017 AEC Excellence Award for Construction, is a prime example of how emerging technologies and BIM can be used to improve collaboration and achieve better outcomes in construction.

From the outset of this project, the use of BIM was integrated into every construction process. With an output of nearly 4,000 drawings for masonry panels, light partition walls, piping shafts, doors, and other elements, contractors were able to prepare their work precisely.

This helped to cut the amount of materials needed for delivery, saving 60 days of construction work. And by avoiding modification and rework, the project cut 30 days from the building schedule.

Robots were used to accurately locate the position of pipe supports, accelerating processes and reducing errors. Outside, drones captured images of the construction site each day to compare and analyze the progress for different areas. Virtual reality is also using data from the BIM models to improve worker safety on the construction site. Learn more.

In construction, most projects have historically been one-offs. While manufacturing has become radically more efficient over the decades, efficiency in construction has made only minor gains. But new kinds of automation and new fabrication processes are finally creating new possibilities on the construction site and through the entire design-to-build process. The projects showcased here are just the beginning.