Sri Lanka’s Extra-Low Voltage (ELV) systems and data-infrastructure sector is evolving at rapid pace. Projects today demand enclosures that can withstand heat, weather, vibration, corrosion, and long-term mechanical load while being delivered faster, with greater precision, and higher levels of customization.

For Cubicoan, this shift demanded a fundamental rethink. Initially, the company operated as a small, marketing-led business, importing and supplying data racks from China and sourcing additional racks through third-party manufacturers while managing customer coordination, installation, and after-sales support. Today, Cubicoan has transformed into one of Sri Lanka’s most reliable manufacturers of server racks, network cabinets, and specialized enclosures built to meet the new realities of modern infrastructure.

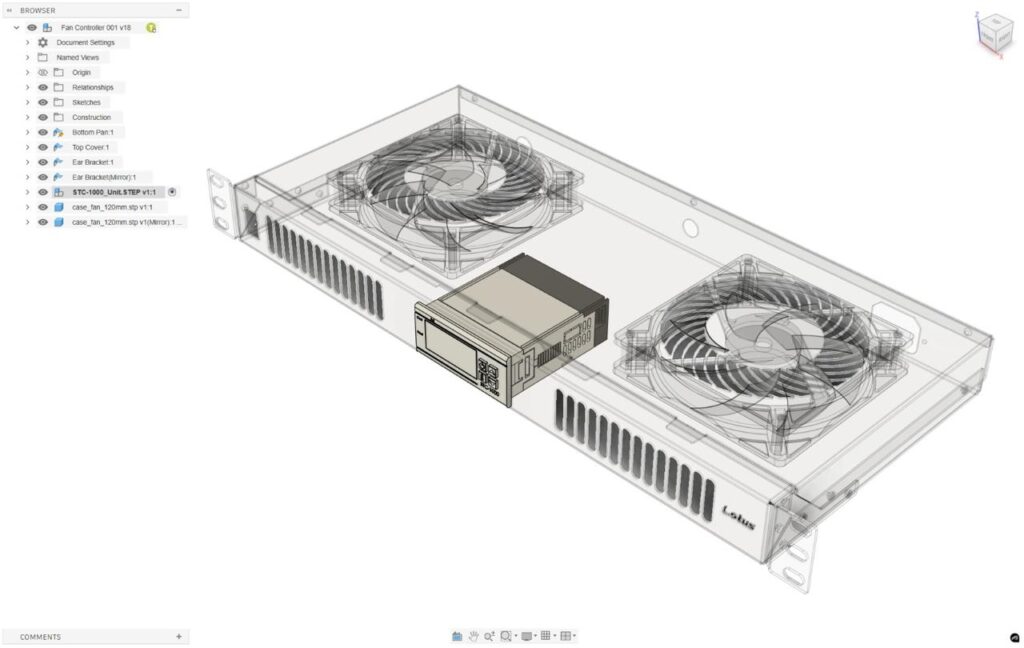

By bringing design, engineering and manufacturing fully in-house and anchoring the transition with Autodesk Fusion, Cubicoan reduced prototyping time by 30-40% and shortened design-to-production lead times by nearly 25%. More importantly, the move reshaped the company’s identity from a coordination-driven operation into a genuinely engineering-first manufacturer.

“Fusion gave us everything: modeling, sheet metal, CAM, collaboration, and cloud access,” says Thilina Tippalagama, Managing Director, Eng., Cubicoan. “It didn’t add complexity. It removed it.”

Scaling Cubicoan’s business

Cubicoan manufactures a wide range of ELV systems and Information and Communications Technology (ICT) enclosures, including server racks, network cabinets, outdoor cabinets, battery enclosures, and customised sheet-metal assemblies. These enclosures are used across Sri Lanka’s data center, surveillance, and telecom industry. They manufacture for the country’s leading system integrators, such as Millennium IT, VSIS, and DEMO. Apart from Sri Lanka, some of the product range is delivered in the Maldives and Seychelles.

It wasn’t always the same for Cubicoan. When Thilina took over as a managing director in 2017, Cubicoan didn’t even have a factory. It outsourced all manufacturing while handling customer coordination, installation, and after-sales. The model was functional, but it was slow and limiting for a business that wanted to innovate. This is what led to Cubicoan’s first major transformation: the decision to bring manufacturing in-house.

“We work on a lot of R&D-heavy projects,” Thilina says. “Our products can go through several iterations in a year. That speed simply isn’t possible when you rely on outsourcing. And keeping our designs safe was equally important. We couldn’t risk IP exposure.”

Becoming a full-scale manufacturer

In 2020, at the height of economic uncertainty, Cubicoan made a bold move. Rather than scale back, they doubled down. The company leased land and began building its own manufacturing plant. The initial shop floor had a very basic setup: a laser cutting system, two precision press brakes, clinch-nut tools, and a 3-axis milling machine after some time.

The goal was clear: Build Sri Lanka’s most agile, R&D-driven enclosure manufacturing ecosystem. One that could design, prototype, and produce with speed. Thilina’s background as a low-voltage switchboard engineer helped shape this push. He understood exactly how damaging manual workflows, inaccurate unfolding, guesswork, and iteration delays could be in the sheet-metal environment. He also knew that traditional desktop CAD was too expensive, too rigid and too hardware-heavy for a small and medium-sized enterprise (SME).

“Being an SME, we simply could not afford traditional CAD licensing,” Thilina says. “And the hardware load was impossible to justify. We needed flexibility, cloud sharing, and something that could help us scale.”

Discovering the features and benefits of Fusion

Fusion became part of Cubicoan almost by accident. Thilina downloaded the trial expecting a lightweight tool, something closer to a hobbyist platform than a serious manufacturing solution. But within days, Fusion began to challenge that assumption. What stood out immediately was how naturally it handled sheet metal bend allowances and rules. Unfolding behaved exactly as his engineering instincts expected. Where earlier tools required manual correction, Fusion delivered accurate, rule-driven flat patterns that made it easy to build reliable templates for the entire team.

Practicality mattered just as much as accuracy. Fusion ran smoothly on modest hardware, removing the need for expensive workstations. Designs were saved automatically to the cloud, allowing Thilina to review work at the factory, continue on a laptop at home, or share models through a browser without installing any software.

The integrated CAM environment opened up milling possibilities without the cost or complexity of separate tools, and the learning curve proved short enough that engineers became comfortable in days rather than months. By early 2023, the decision was clear: every product at Cubicoan from server racks to chilled enclosures would be designed exclusively with Fusion.

“Once I set up our sheet-metal rules, templates, and cloud libraries, the whole team could start designing without friction,” Thilina says. “To be honest, that level of flexibility wasn’t available in any other software we evaluated.”

Managing manufacturing complexity

Cubicoan’s simple-looking enclosures are inherently complex. Many are thin-wall structures that must retain strength despite lightweight construction, while the outdoor cabinets are exposed to heat, moisture, salt spray, and occasional impact. Several designs require strict IP ratings, active cooling systems, and controlled airflow. On top of this, there is the increasing demand for modular, capable of being disassembled for transport and reassembled on site without compromising structural or environmental integrity. Every product from electronics, mounting points, and thermal components demand tight tolerances.

Before Fusion became their primary engineering platform, this complexity often translated into manual unfolding errors, mismatched prototypes, and delays caused by repeated exporting, file transfers, and rework. Designs were typically developed by modifying existing models, stretching or squeezing them, marking sheet metal, cutting and assembling parts, identifying issues, then repeating the cycle, making each iteration wasteful and time-consuming. Each round required additional quality checks and corrections, slowing the entire R&D cycle and making it harder to respond to custom requirements.

Fusion changed that dynamic almost immediately. Its rule-driven sheet-metal environment removed unfolding inconsistencies, while cloud-based collaboration ensured engineers, fabrication teams and partners always worked from the same up-to-date model. What once took multiple rounds of verification became a predictable, reliable workflow.

“Prototyping time is reduced by 30-40% percent,” Thilina says. “Our overall workflows are cut nearly in half.”

Delivering success for the Colombo West Terminal Enclosure Project

One of Cubicoan’s defining projects was the development of a self-contained outdoor enclosure for the Colombo West Terminal CCTV upgrade. The design required a specialised Peltier chiller, corrosion resistance, impact protection and airtight internal cooling.

The challenge was steep. The chiller manufacturer provided no CAD data. There was no standard reference, no drawings, and no easy way to model the system. Cubicoan’s team reverse-engineered the chiller using caliper measurements and recreated it from scratch in Fusion. Once the digital model was built, the enclosure was designed around it with tight accuracy.

“If we had followed the same process going with a template for this chiller project, we would have wasted weeks,” Thilina explains. “Instead, we tested fits, seal lines and mounting points digitally. Fusion made the entire enclosure behave like the real thing.”

The project required structural integrity and airflow pathing both were validated using Fusion’s modeling tools. The enclosure was delivered on schedule with zero prototype failures.

“Fusion changed how we design and build.”

– Thilina Tippalagama, Managing Director, Eng., Cubicoan

Keeping Fusion at the center of Cubicoan’s manufacturing evolution

As Cubicoan continues to expand its engineering and manufacturing capabilities, Fusion will remain a key growth enabler. With three active licenses and plans to add even more, the company is building a digitally native design ecosystem that can scale with demand. What began as a marketing-led facilitation business now has evolved into one of Sri Lanka’s most agile enclosure manufacturers. More than a tool, Fusion has become central to Cubicoan’s engineering confidence, helping the team translate complex customer requirements into reliable, manufacturable products and shaping the company they set out to build.

“Fusion didn’t just improve our workflow,” Thilina says. “It helped us become the company we always wanted to be.”