Explore how connected product development improves key engineering metrics of time-to-market, first-pass yield, and cost of poor quality. Learn how integrating ECAD, MCAD, and PLM reduces latency and errors and how Autodesk Fusion can help.

Elevate your design and manufacturing processes with Autodesk Fusion

Product development teams constantly face pressure to deliver complex designs faster and with fewer errors. One means of alleviating these pressures is to invest in connected development environments that integrate electronic computer-aided design (ECAD), mechanical computer-aided design (MCAD), and product lifecycle management (PLM).

However, justifying this investment requires looking beyond qualitative improvements to hard metrics that demonstrate return on investment. By tracking specific key performance indicators, engineering leaders can objectively measure the impact of unified workflows. Three specific metrics to track are time-to-market, first-pass yield, and the cost of poor quality.

Technology and design metrics

1. Time-to-market

Time-to-market (TTM) is the primary indicator of workflow efficiency. In disconnected environments, TTM drags out as different teams work on disparate file types. For example, mechanical and electrical engineers might exchange data through static files like STEP or IDF. Such a cumbersome transfer process often strips design intent and requires engineers to manually reconstruct models.

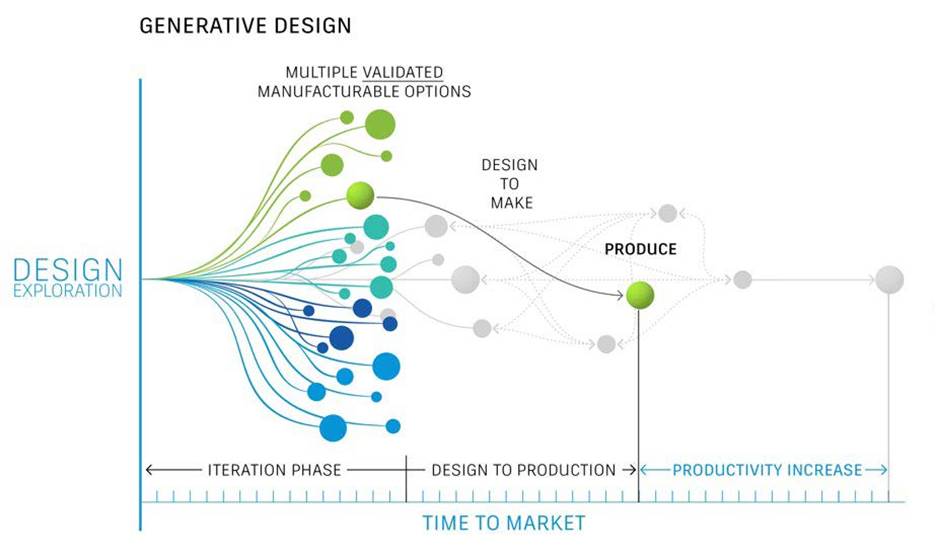

A connected environment eliminates this friction by enabling concurrent engineering. When teams work on shared datasets, the lag time between a design change and its verification disappears. In turn, teams can shorten the overall development cycle and their products can reach shelves sooner.

2. First-pass Yyield

First-pass yield (FPY) measures the percentage of designs that pass verification without rework. Low FPY often stems from spatial conflicts between mechanical enclosures and electronic components. These conflicts typically stay undetected until physical prototyping because 2D representations fail to capture complex 3D spatial relationships.

Integrated design tools allow engineers to visualize thermal and mechanical constraints simultaneously. Detecting these interference issues in the digital domain prevents them from manifesting in physical prototypes. Therefore, the capability increases the likelihood that the first physical build functions correctly.

3.Cost of poor quality

The cost of poor quality (CoPQ) encompasses the financial impact of internal scrap, rework, and field failures. Data mismanagement is a major contributor to high CoPQ. When teams rely on email threads or disconnected spreadsheets to manage bills of materials (BOMs) and change orders, version-control errors become inevitable and manufacturing may produce parts based on outdated files.

Connected PLM systems mitigate this risk by maintaining a single source of truth. Teams avoid using obsolete specifications with automated version history and centralized data management. This control reduces the cost of scrapped parts and manufacturing delays.

Optimizing outcomes with Autodesk Fusion

Autodesk Fusion directly influences these metrics by integrating ECAD, MCAD, and PLM into a single cloud-based platform.

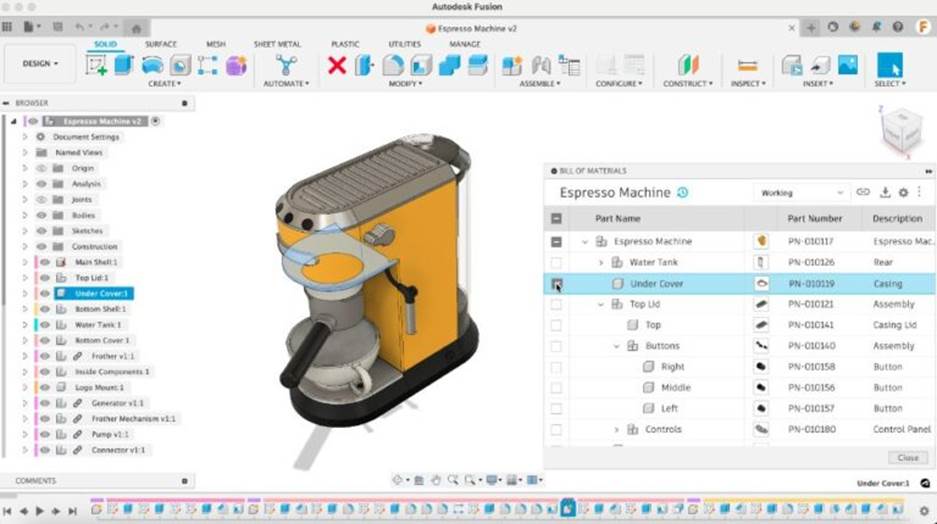

The software’s 3D PCB editor lets mechanical and electrical engineers define board geometries based on actual enclosure models. This direct interaction improves first-pass yield by projecting mechanical profiles directly into the PCB workspace. Engineers can verify component clearance and connector alignment in real-time to prevent the misalignments that typically lead to expensive prototype revisions.

Fusion impacts time-to-market by removing the latency inherent in traditional file-based collaboration. Changes in one domain, such as a shifted mounting hole, generate immediate alerts across the design team. With greater synchronization, teams can achieve faster iteration cycles and a more agile response to specification changes. With Fusion Manage, the platform’s integrated PLM capabilities, teams work faster by initiating change requests and checking BOMs directly alongside the model without switching systems.

Regarding the cost of poor quality, Fusion provides a unified BOM that captures details as they evolve. This feature provides a real-time understanding of the product structure. Change histories document what changed and why it changed. Such traceability makes impact assessments and audits more intuitive. By centralizing this data, Fusion guarantees that everyone from manufacturing to leadership works with the same information. Aligned teams have fewer miscommunications and design errors that would otherwise drive up development costs.

Metrics for success

Validating an investment in connected product development requires a close examination of how technology influences speed, accuracy, and cost. By unifying ECAD, MCAD, and PLM, teams can demonstrate tangible improvements in time-to-market, first-pass yield, and cost of poor quality. Autodesk Fusion provides the necessary infrastructure to drive these metrics in a positive direction, allowing your team to make smarter decisions and higher-quality products.