Elevate your design and manufacturing processes with Autodesk Fusion

Have you ever wanted to import a logo and engrave it on a part? In this segment, we’ll take a deeper look at using different capabilities underneath 2.5 Axis Functionality, along with inserting .svg files as a reference for embossing. We’ll leverage the ‘Trace’ Toolpath Strategy, and truly understand the value of a fully integrated CAM Package by seamlessly interchanging between Modeling and CAM functionality when needed. Enjoy!

Below are highlights of the commands:

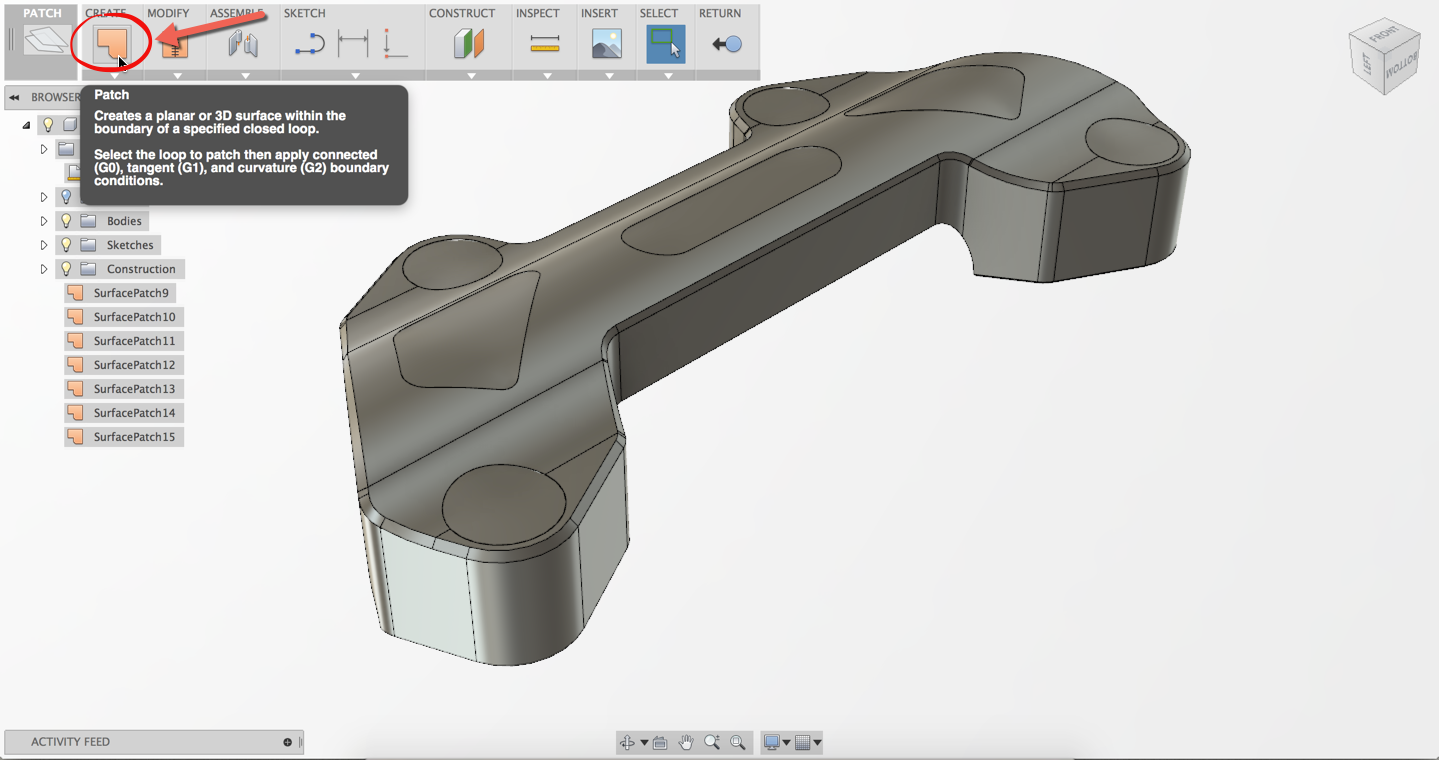

The CREATE PATCH command creates a planar or 3D Surface within the boundary of a specified closed loop. This enables surfaces as model input, allowing surfaces to be taken into account when calculating tool path, eliminating the need to patch holes.

When inserting a .SVG File, take into account the ‘scale plane XY’ value to adjust the size of the imported image.

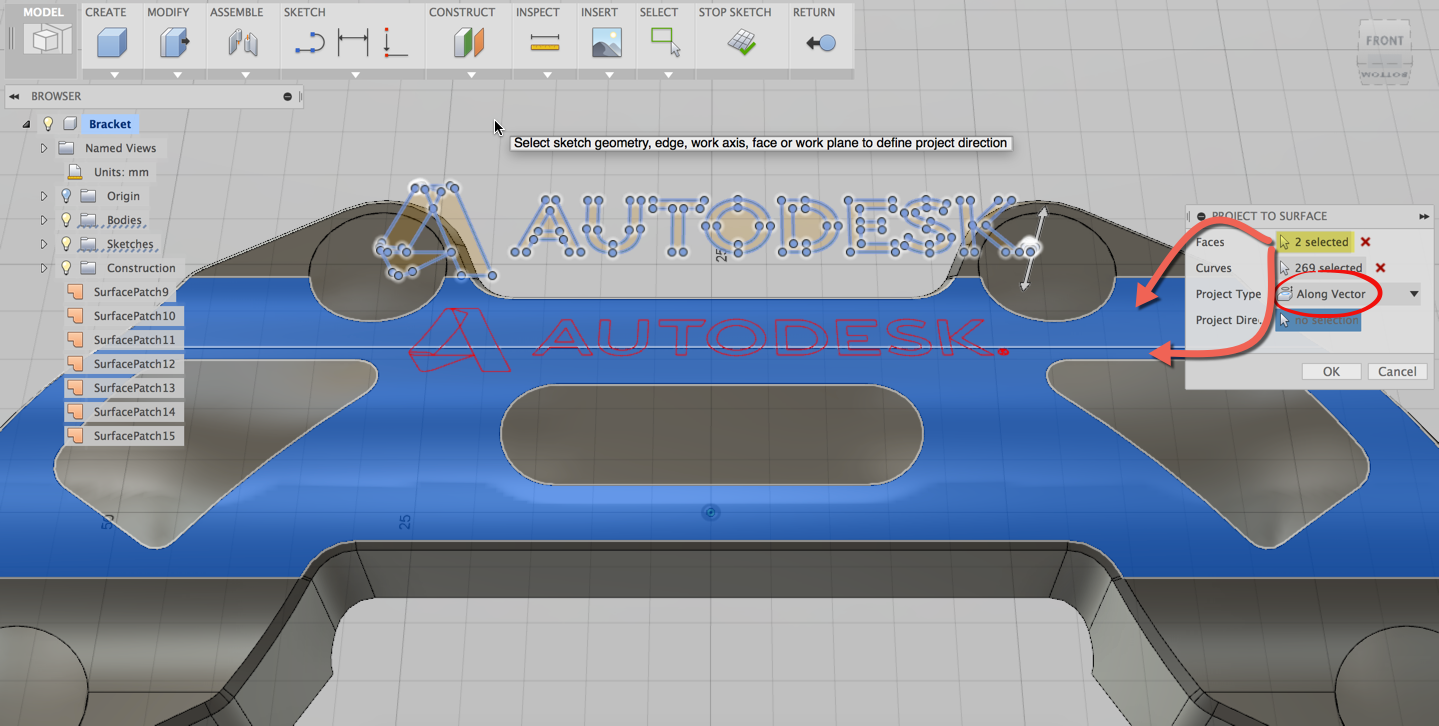

Once the .SVG is scaled to your liking, use ‘PROJECT TO SURFACE’ to have it project on your selected faces.

*TIP* – Make sure you’re still in the sketch of the .SVG Import to select the faces you want to project on.

The TRACE operation allows you to machine along contours with varying Z values and with, or without, left and right compensation. You can leverage the projected sketch and have a tool trace along it’s path.

Under the PASSES TAB, change the Axial Offset to determine how deep you want the tool to cut.

Under the LINKING TAB, UNCHECK ‘Keep tool Down’, to allow retraction of the tool between each letter being machined.