Upliance.ai is India’s first AI-powered cooking assistant, built to make home cooking smarter, simpler, and more creative. It guides users through complex recipes with automated controls, real-time adjustments, and intuitive support, turning everyday meals into effortless experiences. Founded in 2021 under React Labs Pvt. Ltd., Upliance.ai is pioneering a new category of intelligent kitchen appliances in India. Featured on Shark Tank India, the company blends AI, electronics, and mechanical innovation to bring consistency, confidence, and a touch of technology-driven magic into modern kitchens.

Addressing design hurdles with new tools

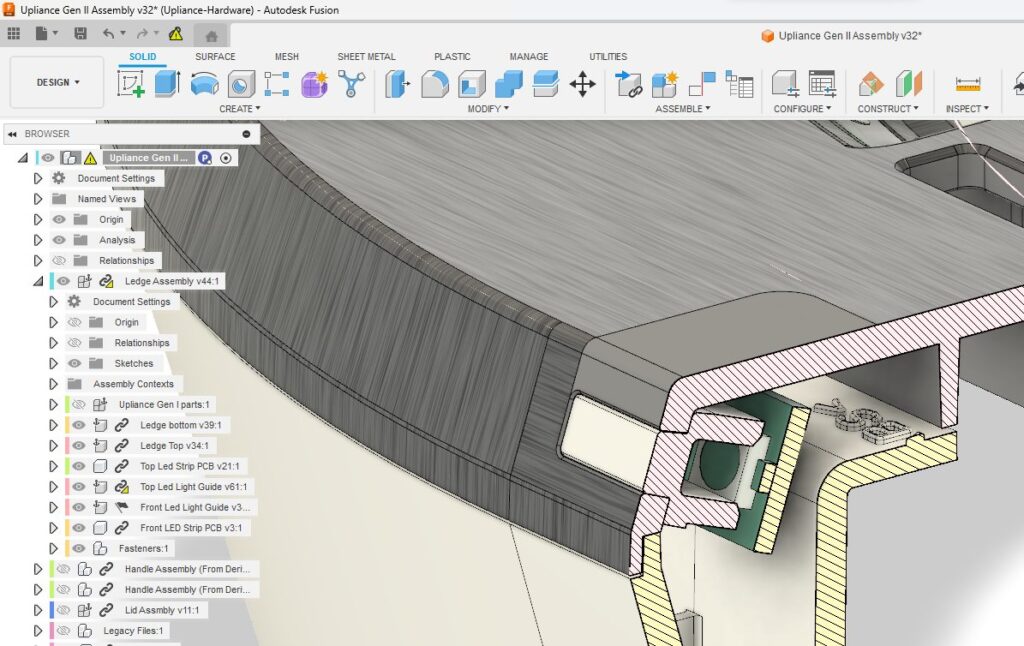

Building a kitchen assistant that combines software intelligence with robust mechanical engineering was no easy task. Development required rapid iteration cycles and close collaboration across cross-functional teams working in sprints. While speed to market was crucial, Upliance.ai also needed to ensure that user-centric design, cooling systems, enclosures, and electronics worked together seamlessly. The product had to be aesthetically pleasing, technologically innovative, functional, affordable, and safe.

One of Upliance.ai’s biggest pain points was the escalating cost of multiple design tool licenses, which quickly became unsustainable as the company scaled. Working across several platforms led to version mismatches, tedious file sharing, and broken links whenever files were renamed. Traditional systems also struggled with synchronization, stability, and file management, slowing iterative development.

Dependence on tools requiring constant internet access further limited flexibility when connectivity was unreliable for R&D and engineering teams. Without a shared real-time workspace, collaboration suffered. Teams often worked on separate local copies, leading to version conflicts, duplicated effort, and time lost to preventable errors.

Given the complexity of its products, Upliance.ai’s design and engineering teams needed a unified platform that supported real-time collaboration, innovation, and cloud flexibility. “Our company was transitioning away from existing design software primarily due to mounting licensing costs,” explains Prasoon Pradeep, Hardware Engineering Manager, Upliance.ai. “Autodesk Fusion emerged as the best alternative available.”

Designing the future of kitchen intelligence

Autodesk Fusion stood out right away as an optimal solution because of how seamlessly it integrated into the team’s workflow. Compared to the continual hassles they had with their previous tools and the connectivity constraints of their existing software, Fusion felt surprisingly seamless. It quickly became an everyday tool, not just for design, but also for iteration and hands-on prototyping.

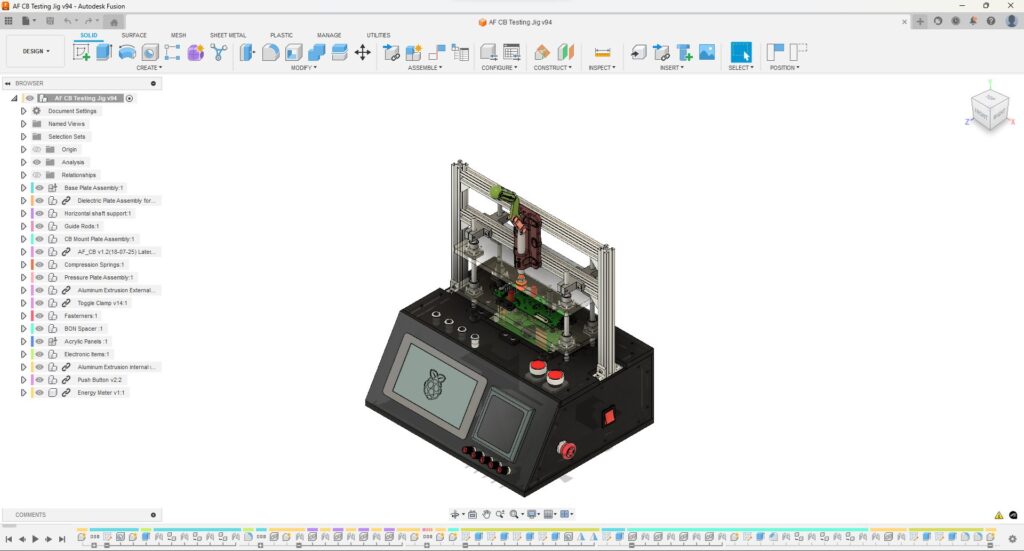

After switching to Fusion, Upliance.ai quickly resolved many challenges in its product development phase. Fusion became the glue connecting the company’s entire workflow—from enclosure design and internal layout to mechanical and thermal validation and CNC programming—creating a continuous feedback-driven loop. The engineering team can now create, iterate, and simulate within a single platform. Real-time synchronisation, cloud-based management, and in-context collaboration eliminated file conflicts and kept everyone aligned with the latest design versions.

“Modern consumer brands are fast-paced. When dealing with a physical product, you must contend with both time and financial constraints,” says Mohit Sharma, CTO of Upliance.ai. “For a product like ours, which will be used in daily chores and home-like settings, the standards are stricter. Considering the complexity of our product, the intuitive intelligence, mechanical strength, temperature resilience, and the nature of an electrical device, we needed something that could help us address all these challenges in one single unified platform.”

Real-time collaboration and version control

The Upliance.ai team especially values Fusion’s version control feature, which allows designs to be modified without breaking links. With both online and offline functionality, Fusion ensures a dependable design process even amid connectivity challenges, giving Upliance the edge to develop robust products faster. Teams can edit, comment, and relink components easily, while integrated rendering accelerates decision-making. This single-source workflow streamlines collaboration between engineering and design, reducing handoff delays and speeding prototyping.

“Fusion’s version control became the backbone of our design workflow,” says Pradeep. We could iterate quickly without worrying about broken links or lost revisions. That stability lets the team spend their time improving the product, not managing files. And the offline functionality gave us the extra speed we needed, as many times our product development team was working remotely.”

Leveraging Fusion’s integrated CAD/CAM environment

Fusion’s ability to handle solid, surface, form, and sheet metal modelling in one program makes it ideal for enclosure-based design. Its manufacturing workspace enables direct toolpath creation for CNC prototyping, while its additive manufacturing tools are integrated seamlessly with 3D printing workflows. Additionally, thermal analysis simulations increased design confidence early in the cycle. Teams can simulate before printing, monitor changes in real time, and iterate rapidly within an integrated workspace.

“Designing intelligent appliances takes precision on all levels: mechanical, thermal, and electronic. When the market is moving quickly, version mismatches and manual file processing are unacceptable. Autodesk Fusion provided us with seamless integration across design, simulation, and manufacturing, allowing us to iterate smarter and produce faster.”

—Prasoon Pradeep, Hardware Engineering Manager, Upliance.ai

From Concept to Prototype in 38 Days

By switching to Autodesk Fusion, Upliance.ai reduced its product development cycle by an impressive 37%. With synchronized designs and integrated simulation, the team minimized rework and eliminated unnecessary file duplication. Advanced features such as in-context editing, relinkable projections, and real-time rendering further accelerated the design process. Even small efficiencies—like saving just one to two minutes per slicing operation—added up to weeks saved across projects. Greater accuracy and speed not only streamlined workflows but also boosted team confidence and accelerated decision-making.

“Fusion has given us a solid foundation that helped unify our mechanical, electrical, and software development operations. This ultimately allowed us to reduce the product development cycle from 60 to 38 days,” says Sharma. “Its features, such as improved draft analysis, version control, and cost projection, directly address the critical engineering needs of the product development phase. This makes it not only ideal for manufacturers but also essential to teams developing complex and smart consumer goods.”

Expanding with PLM

Looking ahead, Upliance.ai is expanding further within the Autodesk ecosystem. The team plans to implement Product Lifecycle Management (PLM) features to bring the entire product journey, from concept and design to testing and production, within a single, connected environment. “We’re satisfied to go deeper into the Autodesk ecosystem, particularly with PLM integration, to manage our complete product lifecycle under one roof,” continues Sharma. “That level of streamlined management is game-changing for consumer brands like us.”

This integration will not only streamline data management processes but also provide greater visibility and control across every stage. For Upliance.ai, PLM adoption represents the next step toward a fully unified digital workflow that connects engineering excellence with operational efficiency.