Autodesk Fusion revolutionizes custom car part design and manfacturing processes by integrating CAD, CAM, CAE, data management and cloud-based collaboration into a unified platform, allowing shops to streamline workflows, enhance precision, and accelerate time-to-market.

The custom car part industry is built on ingenuity, but for decades, fragmented tools and disjointed workflows have stifled innovation. Small to mid-sized shops—crafting everything from vintage car restorations to innovative race components—faced working with numerous disconnected software solutions, file compatibility issues, and communication gaps. The integrated CAD/CAM capability in Fusion removes these barriers, with seamless design and manufacturing integration. Let’s take a look at how Fusion can help your shop ideate faster, build better, and outpace the competition.

Elevate your design and manufacturing processes with Autodesk Fusion

The traditional custom car part workflow: A maze of disconnected tools

Traditional automotive workflows resembled a relay race with too many handoffs. Designers used separate programs for 2D drafting, 3D modeling, and complex surfacing. This disconnected process requires manual file experts, increasing the risk of data loss and corruption. Teams also over-relied on email or shared drives to circulate files, creating version control issues. On-premise software also forced sequential workflows. The fabricator can’t review a design until the designer is finished – delaying feedback and design iterations. Simulation was also a late-stage afterthought. Engineers often waited to test the design until it was “finalized” and then exported it to a separate standalone tool for stress and thermal analysis.

CAM operators often had to re-import designs into yet another tool and painstakingly rebuild features that were lost during file conversions. Even a small error, like a misaligned hole or an incorrect tolerance, could become extremely costly. Without a direct link between design and manufacturing data, any design change meant starting the CAM setup from scratch. This lack of associativity led to significant machine downtime, causing delays of several days even for minor revisions. Remote teams struggled with large file transfers, while clients reviewed static PDFs or physical prototypes. Miscommunication often led to costly rework.

The Fusion advantage – a unified journey from sketch to design to manufacturing

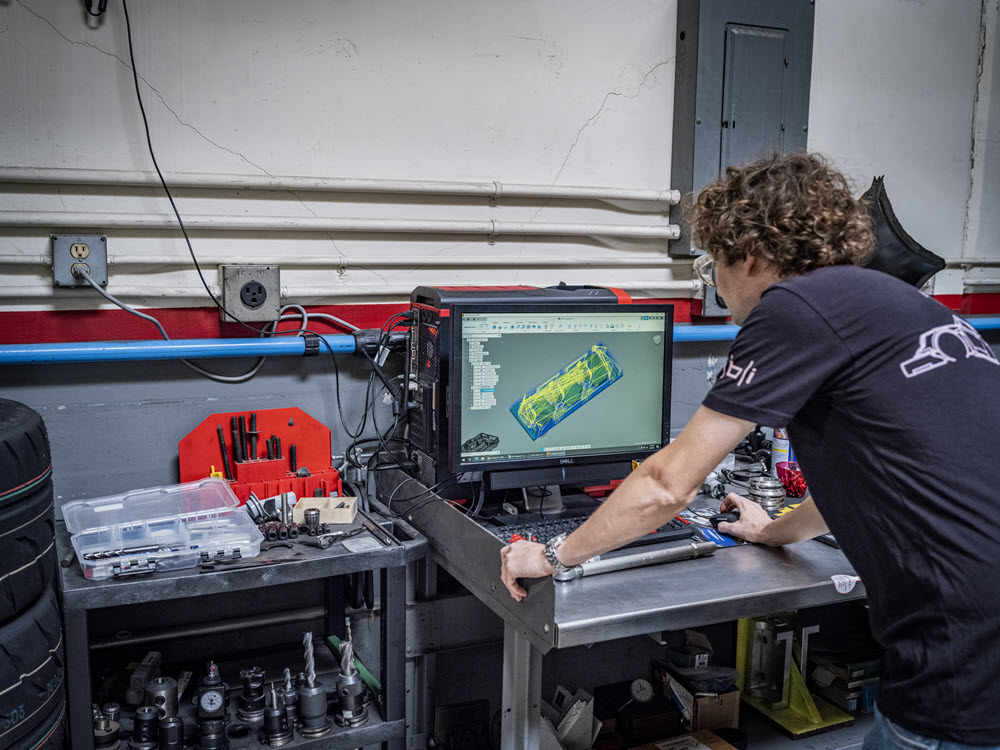

Autodesk Fusion eliminates these disjointed stages into a single, CAD, CAM, CAE, data management, and cloud-connected environment. Here’s how it revolutionizes the custom car part design and manufacturing process:

Design with precision

Autodesk Fusion offers an integrated platform that streamlines the entire automotive design and manufacturing process, combining versatile modeling tools, real-time collaboration, and robust version control. Fusion supports parametric, direct, surface, and mesh modeling techniques. Designers can create intricate, organic shapes—such as custom fenders—while maintaining precise tolerances for critical features like mounting points, all within a single workspace.

Fusion’s cloud-based architecture allows for real-time collaboration among team members, regardless of their location. To manage design iterations effectively, Fusion incorporates a built-in timeline that tracks every modification. Teams can revert to previous versions or branch designs to explore custom variants for different clients, ensuring a comprehensive and organized design history.

Validate earlier, iterate faster

Fusion integrates simulation tools directly in the modeling environment so that engineers can validate designs in real time. In addition, AI-driven generative design capabilities explore numerous design iterations based on specified constraints and objectives. This is particularly beneficial for weight-sensitive components like suspension arms, where the software can produce optimized designs that are significantly lighter while maintaining structural performance.

Redefine the manufacturing processes

Fusion streamlines the transition from design to manufacturing with truly integrated CAD/CAM. Directly generate machine-ready G-code from 3D models, while eliminating the need for intermediate file exports. Complex components like custom intake manifolds with intricate contours can be efficiently machined using 5-axis toolpaths derived directly from the design model.

Associative workflows further enhance efficiency by automatically updating all related CAM operations when design modifications occur. If a client requests a last-minute change, such as altering a diameter, Fusion adjusts the corresponding toolpaths without requiring manual rework. The result – enhanced adaptability throughout the production process.

Fusion supports a variety of manufacturing processes—including CNC milling, laser cutting, and 3D printing—within the same environment. GoWesty, a Volkswagen aftermarket specialist, uses Fusion to produce a range of components, from CNC-machined latches to 3D-printed prototypes, all within a unified workflow.

Break down collaboration barriers

Fusion boosts collaboration across automotive design and manufacturing teams through its cloud-based platform, allowing seamless access to design files from any device. Team members can provide real-time feedback and make on-the-spot decisions. For instance, a restorer can review a vintage part scan on-site, while a machinist simultaneously prepares the shop floor, ensuring synchronized workflows.

Clients can also view and annotate designs directly in their web browsers without the need for specialized software, allowing for quicker iterations and approvals.

Future-proof your shop with Fusion

Fusion not only addresses current custom car part design and manufacturing challenges, but it also equips your shop for future demands through advanced technologies and sustainable practices. By unifying design, simulation, and manufacturing, you can reduce time to market, cut costs by eliminating software bloat and rework, and enhance creativity with tools that turn “impossible” designs into machinable realities.

BBi Autosport’s Betim Berisha put it best:

“Fusion leveled the playing field. We’re out-innovating giants with a fraction of their resources.”

For shops ready to leave fragmented workflows behind, the future of custom automotive innovation is here—and it’s fully integrated.