Choosing between cloud data management and on-premise data management solutions is crucial for modern manufacturing, with cloud systems offering scalability, real-time collaboration, and enhanced security.

The way businesses handle data is just as important as the products they design and manufacture. With the digitization of operations and the integration of Industry 4.0 technologies, choosing between cloud and on-premise solutions for data management becomes an important decision. It can directly impact scalability, security, performance, and long-term competitiveness. Let’s dive into each model, their respective benefits, and why considering cloud data managment may be a good fit for your organization.

Elevate your design and manufacturing processes with Autodesk Fusion

Cloud vs. on-premise data mangement

Cloud product data management is a centralized system hosted in the cloud that manages all product-related data. It includes design files, BOMs, revisions, approvals, and more—throughout the product development lifecycle, enabling real-time collaboration and access from any device. Its primary benefits include:

- Scalability: Quickly adapt to change needs without the need for upfront infrastructure costs.

- Collaboration: Teams can easily work across different locations on the same models and data at the same time.

- Accessibility: All stakeholders can access information at any time, from any device.

- Automatic updates & security: Cloud PDM platforms offer enterprise-level security, encryption, and compliance protocols.

On-premise data management systems reside entirely within a company’s own infrastructure, offering full control over software, servers, and data. Its primary benefits include:

- Complete control: Businesses manage everything, including updates and integrations.

- Data security: Sensitive data never leaves the site.

- Legacy system integration: On-premise solutions may work better with older, specialized machinery.

Choosing between a cloud or on-prem data management is not just a technical issue—it defines how fast your company can innovate, collaborate, and compete.

The solution: Cloud data management

With digital manufacturing processes becoming more and more important, many manufacturers are finding that cloud data management offers the best path forward enhancing efficiency and accelerating time to market. In fact, according to Deloitte’s 2025 Smart Manufacturing and Operations Survey, 57% of manufacturers are using cloud computing and leveraging data analytics.

Cloud data management acts as a single source of truth for product data. Whether engineers are working on-prem or from remote sites, all stakeholders access the same up-to-date information.

Designers, suppliers, and production managers can work on the same file simultaneously, with real-time feedback, comment tracking, and automated version control. This leads to less errors, improves design cycles, and reduces time to market.

Cloud data management solutions are backed by enterprise-grade security, encryption, and compliance protocols. They scale with your needs—no more guessing future server capacity. These solutions also offer APIs and tools that integrate with MES, PLM, ERP, and other systems. Machine-collected data can inform design updates, closing the loop between design and manufacturing.

As manufacturing continues to evolve at lightning speed with technologies such as AI, automation, digital twins, and IoT, cloud-solutions are more agile and adaptable.

Autodesk Fusion – Built-in cloud data management for modern manufacturing

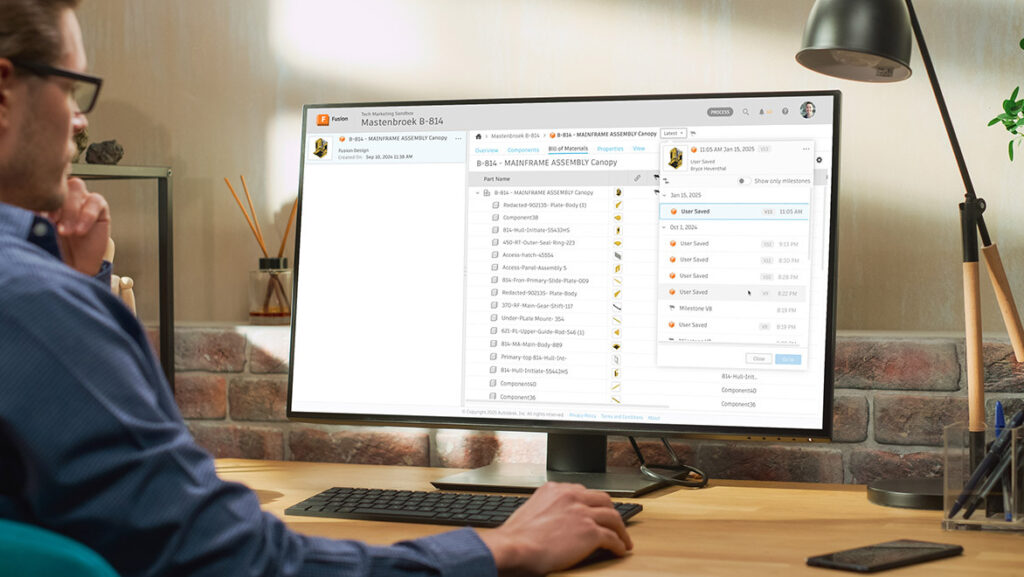

Fusion is a fantastic solution for built-in cloud data management. It’s a comprehensive product development solution that integrates, CAD, CAM, CAE, PCB and data management tools. Its cloud-based platform allows teams to collaborate in real-time, regardless of their location, ensuring everyone has access to the most up-to-date information. This seamless integration reduces errors, improves design cycles, and accelerates time to market.

“Fusion helped us a lot because we were working with three types of companies, and therefore you need one hub where all the data and all the R&D work is being stored and managed. Fusion helped us save on costs because if you take an average design process of such an implementation, it takes up to 24 months. We did it in six months.”

-Thomas Adam Saier, Head of Design, O’NEAL Europe

With its concurrent design capabilities, Fusion enhances manufacturing efficiency. It allows multiple team members to work simultaneously in a central location, accessing data and real-time workflows. This eliminates bottlenecks by enabling edits, comments, and reviews, reducing delays and miscommunication. Fusion also automates Bill of Materials (BOM) management from CAD data, enabling simultaneous edits and the addition of relevant metadata. This aids in reducing errors and production delays. In addition, users can easily maintain consistency and accuracy in product documentation with predefined or customizable properties. This ultimately makes collaboration amongst your teams easier, eliminates headaches associated with errors and inconsistencies and speeds up the design and manufacturing processes.

Modern manufacturing requires speed, intelligence, and flexibility. With real-time and high-stakes decisions driving the manufacturing floor, the right data management solution can lead to better production efficiency, compliance adherence, and higher-quality outcomes. Autodesk Fusion delivers on all of this.