Learn how the 5-axis machining capabilities in Fusion offer enhanced precision, efficiency, and versatility, driving streamlined workflows from design to production and addressing key manufacturing challenges.

In today’s fast-paced manufacturing environment, precision and efficiency are critical. As technology rapidly evolves, the tools and methods used to create complex designs and intricate parts need to advance as well. Autodesk Fusion for Manufacturing, a comprehensive cloud-based CAD, CAM, CAE, PCB, and data management solution that brings robust 5-axis machining capabilities to the forefront.

Elevate your design and manufacturing processes with Autodesk Fusion

What is 5-axis machining?

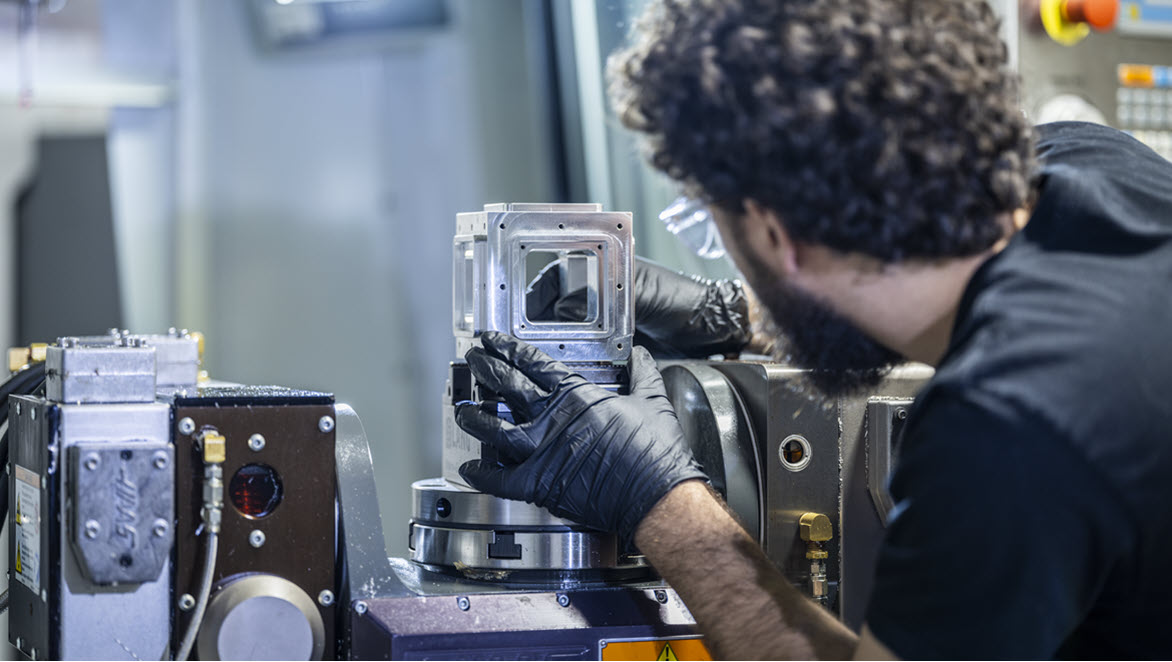

5-axis machining refers to the capability of a CNC machine to move a workpiece or tool along five different axes simultaneously. These axes include the traditional X, Y, and Z linear movements, along with two additional rotational movements (A and B axes). This approach allows for the machining of complex shapes and geometries that are difficult or impossible with traditional 3-axis machining.

Benefits of 5-axis machining

- Enhanced precision: With the ability to approach the workpiece from multiple angles, the need for multiple setups greatly reduces. This leads to the reduction of errors and ensures higher precision in the final product.

- Improved surface finish: The continuous movement of the tool along the five axes allows for smoother transitions and finer surface finishes.

- Reduction in lead time: By enabling complex machining in a single setup, overalll lead time is reduced. This acceleration in production is critical for industries where time-to-market is a competitive factor.

- Cost efficiency: Although the initial investment in machinery may be higher, the reduction in labor, setup time, and material waste leads to long-term cost savings.

Autodesk Fusion for Manufacturing

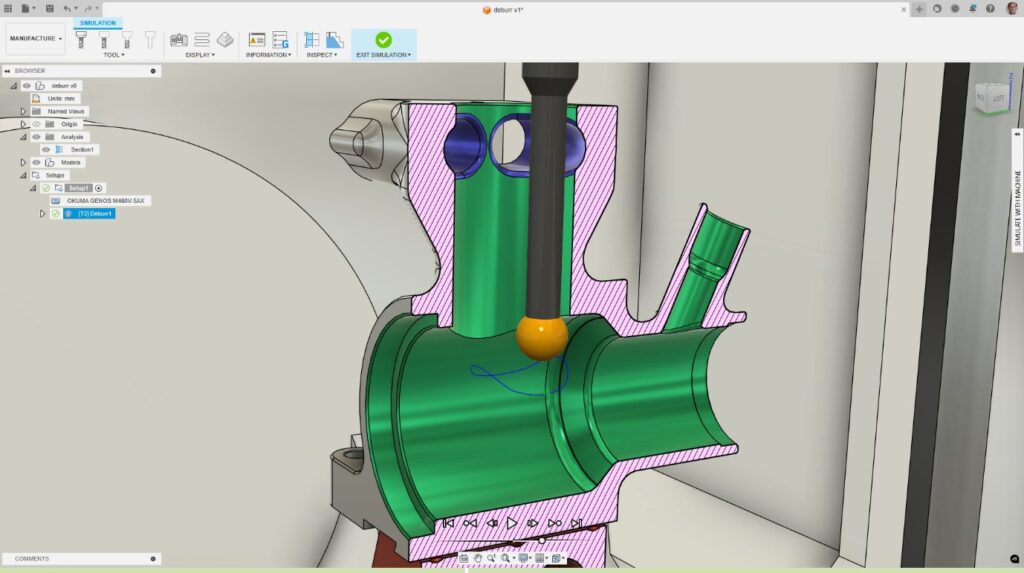

Fusion for Manufacturing significantly enhances the capabilities of Fusion by offering advanced CAM programming tools tailored for complex manufacturing needs. These tools include positional 5-axis machining (3+2) and simultaneous 4- and 5-axis machining.

Positional 5-axis machining allows the cutting tool to reorient relative to the workpiece. This aids in the production of complex parts with fewer setups. It also enables the machining of hard-to-reach features using shorter, more rigid cutting tools. Simultaneous 4- and 5-axis machining includes specialist strategies and tool axis controls to ensure efficient, collision-free machine motion.

Fusion for Manufacturing also provides robust process simulation tools to validate manufacturing processes. For CNC machining, accurate 3D models of the machine help identify potential collisions, axis over-travel, and other issues before they become costly mistakes. For additive manufacturing, simulations can predict print failures, allowing you to address problems in a virtual environment. These simulations are crucial for minimizing waste and ensuring the efficiency and accuracy of your manufacturing processes.

In addition, Fusion for Manufacturing supports in-cycle probing and part alignment. These inspection routines help set up machine datums, measure part accuracy during and after machining, and automate the setup of large, heavy, or non-prismatic parts. This functionality is essential for maintaining high productivity and quality in your manufacturing operations.

Overall, Autodesk Fusion for Manufacturing is designed to accommodate the advanced needs of growing businesses. It provides a comprehensive suite of tools and strategies for multi-axis CNC machining, process simulation, and efficient part alignment. These capabilities ensure your production processes are optimized, safe, and capable of handling complex manufacturing challenges.

Conclusion

5-axis machining represents a significant leap in manufacturing technology, offering unparalleled precision, efficiency, and versatility. Autodesk Fusion for Manufacturing provides the capabilities needed to achieve exceptional results. Embrace the future of manufacturing today.