Effective packaging design that incorporates aesthetics, functionality, sustainability, and cost-efficiency, is important for manufacturers to enhance consumer appeal and brand success. Autodesk Fusion offers comprehensive tools to streamline and optimize the design process.

Elevate your design and manufacturing processes with Autodesk Fusion

Packaging design plays a critical role in the success of a product and is expected to reach $32.42 billion by 2023. For manufacturers, effective packaging design directly impacts product sales, brand perception, and consumer satisfaction. In this article, we’ll explore the key factors to consider in packaging design, why it’s important to manufacturers, and how Autodesk Fusion can aid in creating innovative and efficient packaging solutions.

Factors to consider in packaging design

Aesthetics and branding

The visual appeal of packaging is often the first point of contact between the product and the consumer. A well-designed package should attract attention, convey the brand’s message, and differentiate the product from competitors. Primary considerations should include:

- Color: Colors should align with brand identity and evoke the desired reactions from consumers.

- Typography: Text placement and fonts should be clear, legible, and consistent with the brand.

- Imagery: Use high-quality images that enhance visual appeal and provide information about the product.

- Shape and structure: Unique shapes and innovative structural designs make a product stand out on the shelves.

Functionality

Packaging should be functional, practical, and easy to open and use. Key considerations should include:

- Protection: The packaging should protect the product from damage during transportation and storage.

- Ease of use: The package should be easy to open, reseal, and dispose of.

- Portability: Consider how the package affects carrying and storing the product.

- Information: Labels and instructions should be easy to reach and contain all necessary information.

Packaging design sustainability

Sustainable packaging has become a critical factor with the increase in environmental awareness. Manufacturers should consider eco-friendly materials and practices to reduce their environmental footprint. Key aspects include:

- Material selection: Consider using recyclable, biodegradable, or reusable materials.

- Manufacturing process: Attempt to minimize waste and energy consumption during production.

- End-of-life: Design packaging that is easily recycled or repurposed.

Cost-effectiveness

Manufacturers must balance the need for high-quality, attractive packaging with budget constraints. Considerations include:

- Material costs: Choose cost-effective materials without compromising quality.

- Production costs: Implement efficient manufacturing processes to reduce costs.

- Transportation costs: Design packaging that optimizes space and reduces transportation costs.

Regulatory compliance for packaging design

Packaging must adhere to various regulatory standards and requirements, which tends to vary by region and industry. Manufacturers need to ensure compliance with:

- Safety standards: Create packaging that is safe for consumers and does not pose health risks.

- Labeling requirements: Label packaging accurately with items such as ingredients, instructions, and other relevant details.

- Environmental regulations: Ensure compliance with regulations regarding the use of certain materials and disposal practices.

The importance of packaging design to manufacturers

Packaging design helps establish and maintain a brand’s identity. It also fosters brand loyalty, making the brand easily recognizable and distinguishable from competitors. Consistent and appealing packaging ensures that consumers can identify and connect with the brand effortlessly.

Effective packaging design plays a significant role in attracting consumers and influencing their purchasing decisions. Eye-catching designs coupled with clear information and functional packaging help to drive sales. Even more, packaging that aligns with consumers’ values, such as sustainability, can further boost engagement and loyalty.

Proper packaging is also important for product protection, so that items reach consumers in top-quality condition. Its necessary to safeguard against physical damage, contamination, and spoilage, to reduce returns and increase customer satisfaction. Reliable packaging is a key factor in maintaining product integrity from production to consumption.

Packaging also serves as a powerful marketing tool, communicating the product’s features, benefits, and brand values. Innovative packaging designs can generate excitement and word-of-mouth promotion, significantly aiding the product’s overall marketing strategy. Further, well-designed packaging leads to cost efficiency across various areas, including production, transportation, and storage. Efficient use of materials and space can minimize costs and maximize profitability. By optimizing packaging design, manufacturers can achieve significant savings while delivering a high-quality product experience.

How Fusion supports superior packaging design

Autodesk Fusion is a comprehensive, cloud-based CAD, CAM, CAE, and PCB software with built-in PDM that offers a range of tools and features to aid in packaging design. Here’s how it can help:

3D modeling and visualization

Fusion provides powerful 3D modeling capabilities for designers to create detailed and accurate representations of packaging concepts. This helps in visualizing the final product, identifying potential issues, and making necessary adjustments before production.

Simulation and analysis

Simulation and analysis tools help test the durability and functionality of packaging designs. Designers can simulate various conditions, such as transportation and handling, to ensure the packaging meets the required standards and protects the product effectively.

Material selection and optimization

Fusion helps designers experiment with different materials and optimize their use. This includes evaluating the environmental impact, cost, and performance of various materials to help make informed decisions.

Collaboration and communication

Fusion enables collaboration among design teams, manufacturers, and stakeholders. Its cloud-based platform and built-in PDM allows for real-time sharing of designs, feedback, and modifications, streamlining the design process and ensuring everyone is on the same page.

Rapid prototyping

Designers can create physical models of packaging designs quickly to assess the practicality and aesthetics of the design, making necessary adjustments, and speeding up the development process.

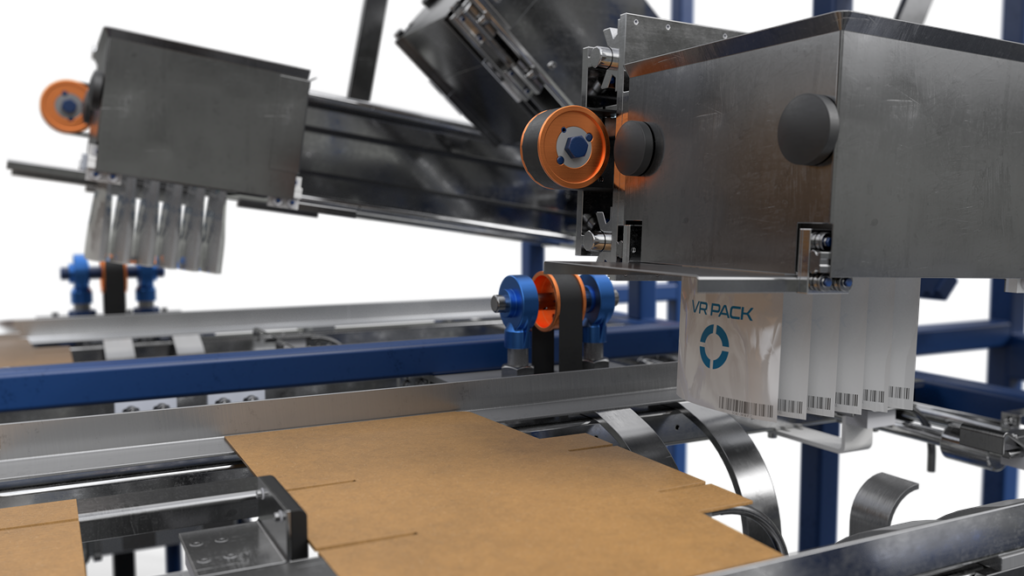

Integration with manufacturing processes

Integrated CAD/CAM ensures that the transition from design to production is smooth and efficient. This includes generating precise specifications and instructions for manufacturers.

Sustainability

With the Manufacturing Sustainability Insights Add-on, designers can analyze the lifecycle of materials, evaluate energy consumption, and explore eco-friendly alternatives, aiding in the creation of sustainable packaging solutions.

Remain competitive with unique packaging design

In a competitive marketplace, the importance of packaging design cannot be overstated. It is a key driver of consumer attraction, brand loyalty, and product protection. With the advanced tools provided by Autodesk Fusion, manufacturers can stay ahead of the curve, ensuring their packaging designs are not only visually appealing but also functional, sustainable, and cost-effective.