Learn how the PDMC collection, including Autodesk Inventor, AutoCAD, and Fusion can take your manufacturing processes to new heights.

From 2D to 3D with the PDMC collection

Fusion Operations: Manufacturing Insights at Your Fingertips

Fusion Operations provides real-time data to optimize scheduling, inventory, and quality.

Although 3D design applications have been available to manufacturers for over 20 years, many companies still heavily rely on 2D design. This primarily stems from the fact that delivering a project often requires a combination of both 2D and 3D design. Similar to office or shop-based tools, it’s all about using the right tool for the job.

Continuing to use 2D primarily in AutoCAD for specific use cases remains essential for many manufacturers. One of the key benefits of working with AutoCAD and Inventor is the ability to leverage the associativity that both provide.

Users can reference 2D drawings from AutoCAD directly into Inventor from the PDMC collection for faster 3D model creation. Also, since the Inventor drawing environment saves as DWG, view information generated from the 3D model can be associatively placed back into the AutoCAD environment. This creates a truly flexible workflow, enabling both environments to remain associative with each other.

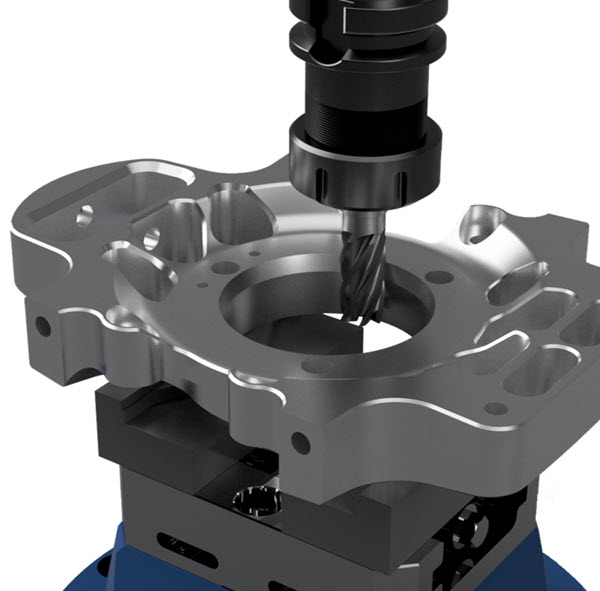

Inventor CAM

Autodesk Inventor CAM provides a seamless workflow from design to manufacturing, as it is integrated directly within Inventor. It includes functionality for 2.5 to 5-axis machining, as well as lathe and mill-turn applications, making it the easiest workflow for Inventor users, who never have to leave the interface or exchange data.

Fusion for manufacturing

That said, for the latest cloud-based capabilities, Fusion is the go-to solution in the PDMC collection. Autodesk’s newest CAM strategies and manufacturing technologies are integrated into Fusion. Depending on your requirements, you may want to utilize either subtractive or additive manufacturing methods, supported by Fusion.

Fusion’s additive manufacturing benefits include organic creation tools for quick prototype development, printer templates, and the optimization of the printing process. This includes support structures, fill definitions, orientation, and packing options. Advanced capabilities in the Fusion Design Extension, such as lattice creation preview and design guidance, aid in making informed decisions when developing parts.

Moving onto subtractive manufacturing, users can take advantage of the robust manufacturing environment in Fusion to generate toolpaths for milling or turning parts. It now includes more comprehensive strategies that support complex machining requirements for organizations with intricate manufacturing needs.

Fusion also include support for on-machine verification and inspection processes. This enhances quality control directly within the manufacturing workflow. It also allows for precise measurements and validations to make sure that the parts meet the required specifications.

If you’re using Inventor models, there’s still the advantage of consuming model data associatively. Users can appreciate any changes in the design, whether they originate from Inventor or Fusion. This integration ensures that updates are consistently reflected across platforms, maintaining the integrity of the design.

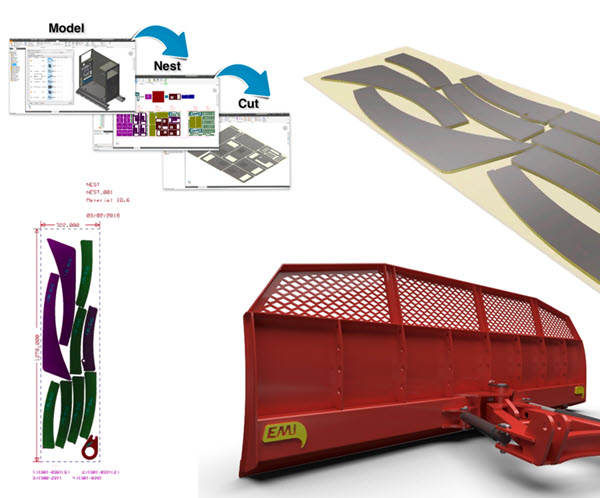

Nesting capabilities in the PDMC collection

When dealing with multiple flat components of various shapes and sizes, creating a nested layout that minimizes material waste can be challenging. Autodesk Inventor Nesting and Fusion’s Manufacturing Extension are designed to optimize yield from raw materials. Nesting studies can be created and updated to reflect any changes in the design. This allows you to compare different nesting studies to optimize efficiency. You can then use Inventor CAM or Fusion CAM to generate router or laser toolpaths, ensuring precise and efficient cutting.

FS Elliott harnessed the power of iLogic to automate the 3D modeling of some of their most complex products. One notable achievement is their modeling of impellers, where they reduced the time required from days to just 15 minutes. Manufacturing an impeller is not for the faint-hearted, as it consumes significant time and resources. Tools that can optimize strategies are thus critical in minimizing effort and maximizing efficiency.

“iLogic has allowed us to create more complex designs with hundreds of points that would take a long time to do manually.” – Alex Curtin, Product Manager, FS-Elliot

PDMC collection for manufacturing

The PDMC collection provides robust solutions for both additive and subtractive manufacturing. It offers advanced tools and integrations that streamline workflows, optimize material usage, and enhance the precision and efficiency of complex manufacturing processes.

Autodesk Product Design & Manufacturing Collection

Solve interesting problems efficiently with the ultimate set of engineering apps.

Learn More