Explore how 5-axis machining enables greater precision and flexibility, and how Autodesk Fusion empowers designers to harness this advanced manufacturing method.

Current manufacturing technology is the most sophisticated it’s ever been. Engineers have developed manufacturing methods that help meet the newfound need to produce complex parts with precision and efficiency. Among these methods, 5-axis machining has become an essential capability in competitive production environments.

While traditional 3-axis machining has long been a staple in subtractive manufacturing, the transition to 5-axis technology offers new opportunities for more intricate parts, tighter tolerances, and shorter lead times. Read on to learn more about 5-axis machining and how Autodesk Fusion for Manufacturing brings this technology to designers’ fingertips.

Elevate your design and manufacturing processes with Autodesk Fusion

The technology behind 5-axis machining

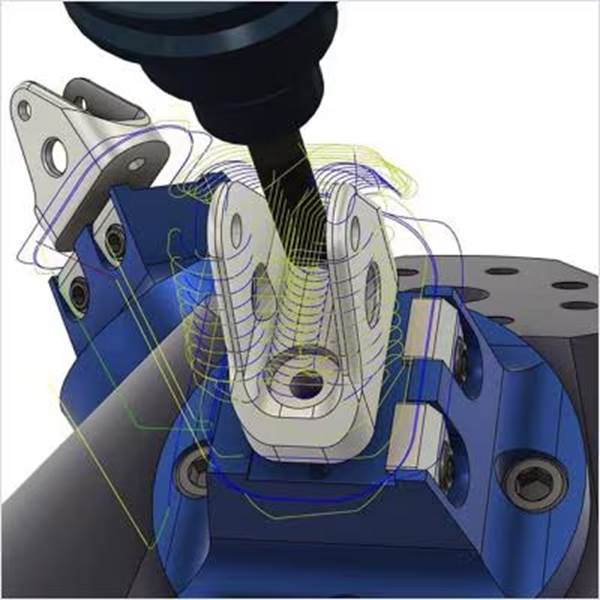

Fundamentally, 5-axis machining refers to a computer-controlled process where the cutting tool moves along five different axes simultaneously. These include the standard X, Y, and Z linear axes, along with two additional rotational axes. These are often referred to as A and B or A and C, depending on the machine configuration. This expanded range of motion allows the tool to approach the workpiece from virtually any direction. This reducing the need for multiple setups and fixtures.

Unlike 3-axis machining, where the tool is fixed vertically and the part must be repositioned manually or with basic tilting, 5-axis systems dynamically orient the tool or table to access complex angles in one continuous motion. The true power of this capability comes to light when handling contoured surfaces, deep cavities, or features on multiple planes. From a design perspective, 5-axis systems allow for greater freedom in form. Components can be made lighter, more compact, and optimized for performance without being limited by tool accessibility.

Although supporting increased complexity is a major draw of 5-axis machining, it also provides part accuracy and surface finish benefits. Because the tool maintains a more optimal cutting angle throughout the operation, the risk of tool deflection is reduced, leading to better geometric fidelity. Moreover, the ability to complete parts in fewer operations shortens production time, minimizes cumulative error, and improves consistency across production runs.

Designing for 5-axis with Autodesk Fusion

Autodesk Fusion for Manufacturing presents a clear path from concept to finished part within a single environment.

It offers a comprehensive environment for 5-axis machining that tightly integrates design and manufacturing. With capabilities that support both 3+2 positioning and full simultaneous 5-axis motion, Fusion empowers users to machine complex parts efficiently and accurately. Advanced features like automatic tool tilting, multi-part programming, adaptive roughing, and collision avoidance simplify precision across intricate geometries.

Another benefit of Fusion for Manufacturing includes the ability to minimize setup changes. This reduces production time and helps maintain tighter tolerances by keeping parts in a consistent orientation. Toolpath control functionality enables lead, lag, and side angle adjustments so that surface finishes are optimized and material engagement is improved. Meanwhile, automatic collision detection and tool tilt adjustments add a layer of safety and reliability when machining difficult-to-reach features.

Fusion supports a smooth workflow from design to part, encompassing everything from angle control to surface quality optimization. It also supports a shared environment where CAM strategies directly tie to design models, improving communication, and reducing errors. Adjustments to features or tolerances can be immediately reflected in updated toolpaths for a closed feedback loop between design and manufacturing.

Advanced machining made accessible

5-axis machining is an advancement in manufacturing flexibility and precision. It offers new ways to approach complex geometries and tight tolerances. With Fusion for Manufacturing, these capabilities are made accessible within a comprehensive CAD, CAM, CAE, PCB, and data management platform that supports faster iterations, better part quality, and more ambitious product designs.