This post is also available in: Français (French) Italiano (Italian) Deutsch (German)

Automation and AI-driven quality control is transforming manufacturing by enabling real-time defect detection, predictive quality management, and automated inspection to reduce errors and maximize efficiency. Autodesk Fusion integrates automation and AI across the product development lifecycle to accelerate high-quality production and continuous improvement.

Elevate your design and manufacturing processes with Autodesk Fusion

Manufacturing processes have become increasingly complex as companies strive for higher-quality products with shorter lead times, tighter tolerances, and fewer defects. With these pressures and a recent proliferation of manufacturing data, automation and artificial intelligence (AI) have become powerful tools for quality control. Whether defect detection or predictive quality management, automation and AI are reshaping quality assurance by integrating intelligence directly into the production environment. With a newfound ability for proactive decision-making, designers can raise the bar for high-quality manufacturing.

AI-powered quality and inspection automation

Automation and AI significantly enhances quality control, primarily due to its ability to analyze vast amounts of production data in real time. Machine learning algorithms can analyze sensor inputs, process histories, and environmental variables to identify subtle patterns that precede defects. Based on this data and predictive algorithms, quality control specialists can intervene on the line before a defect ever materializes.

An example is in high-volume manufacturing, where computer vision systems powered by AI have replaced manual visual inspections with high-speed, pixel-level defect recognition. On the base level, these systems can already identify scratches, warping, or misalignments with far greater accuracy than humans. However, when combined with learning capabilities, these systems become increasingly precise with each batch analyzed. Such capabilities reduce false positives and increase confidence in automation processes, allowing human operators to focus on other high-value tasks.

Similarly, AI-powered predictive quality management also enables continuous improvement across varied pillars of the production lifecycle. For example, AI models trained on historical and live process data can predict the likelihood of specific failures and suggest optimized machine settings to prevent them. This feedback loop ensures that manufacturing conditions stay within optimal quality parameters, minimizing variability and reducing scrap rates. By correlating quality metrics with upstream variables such as supplier batch characteristics or environmental conditions, AI can also empower operations teams to implement systemic changes rather than one-off fixes.

Automation and AI tool in Fusion for enhanced manufacturing quality

Autodesk Fusion is a prime example of how automation and AI-driven tools can be embedded directly within the design-to-manufacture workflow to enhance quality control.

One game-changing feature is generative design, which utilizes AI algorithms to produce thousands of potential design solutions based on specified constraints such as load, material, and manufacturing method. The first benefit is in facilitating the design iteration process through rapid, AI-guided exploration of multiple viable solutions. To take things further, generative design also improves final part performance by finding geometries that minimize stress concentrations and increase structural integrity.

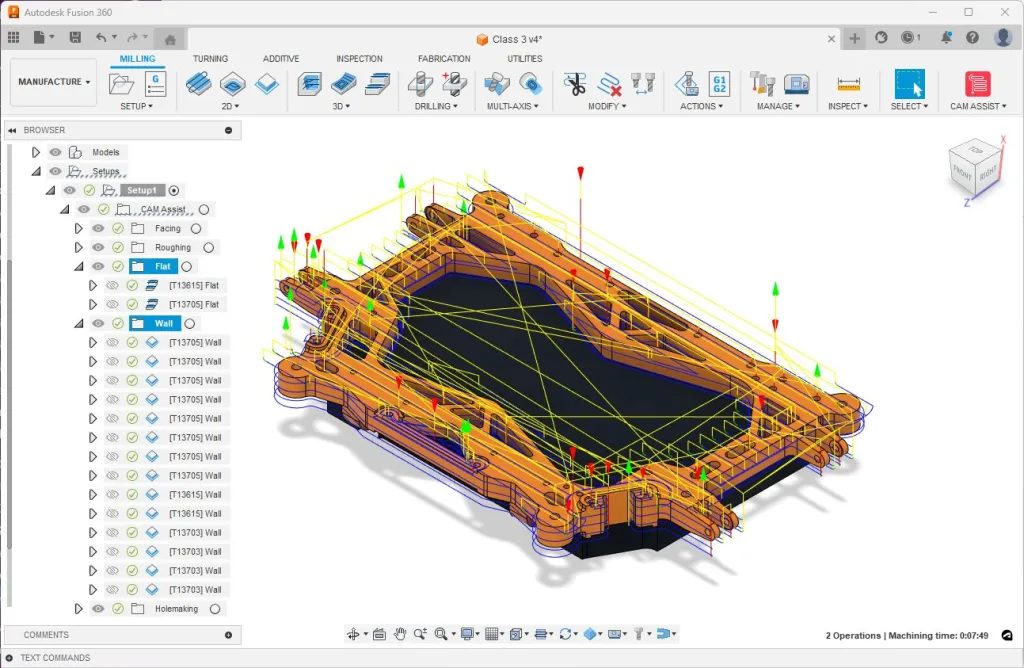

Fusion’s CloudNC CAM Assist Automation Add-in extends this intelligence to the CAM environment. It analyzes the geometry of a part to automatically generate machining strategies that optimize toolpath efficiency and surface finish. By ensuring precise tolerances and consistent machining across production runs, the system greatly lowers the risk of human error in programming.

Drawing Automation in Fusion takes things a step further by reducing the burden of documentation. This AI-powered feature automatically generates fully dimensioned 2D drawings from 3D models, eliminating errors that can occur during manual drafting. With strong documentation, machinists and quality engineers can always reference the correct specifications for accurate fabrication and inspection.

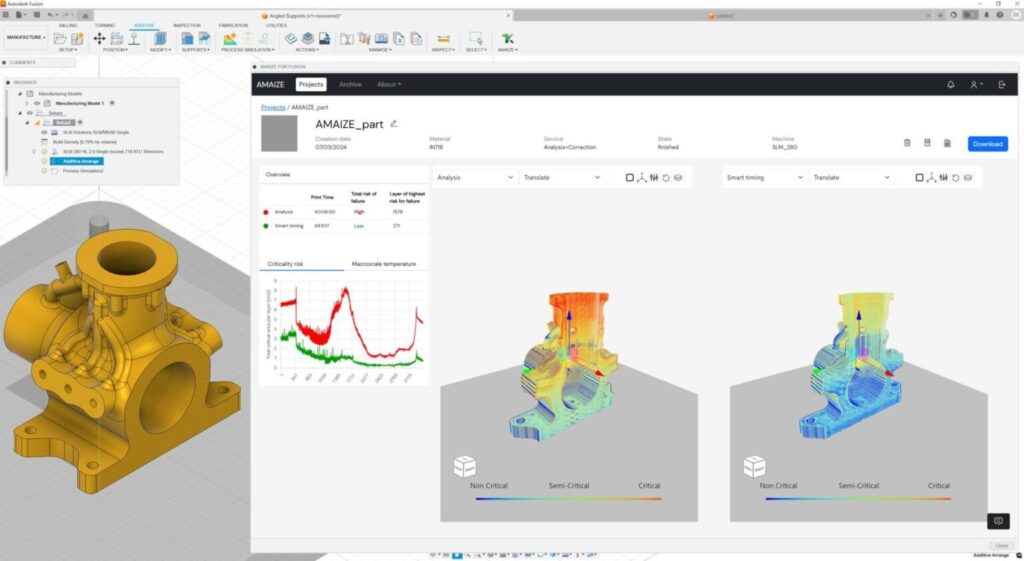

Finally, for manufacturers leveraging additive processes, the AMAIZE add-in uses AI to predict and correct issues in metal 3D printing. Analyzing thermal distortion, residual stresses, and geometric deviations before printing begins allows users to preemptively adjust print parameters for optimal results.

Harnessing the power of automation and AI

If you’re a manufacturer looking to keep pace with the rest of the industry, AI is non-negotiable. Between the predictive defect detection, improved design outcomes, and better ways to document the process, AI offers teams a myriad of improvements that are otherwise unattainable. Fortunately, Autodesk Fusion consolidates all of these features within a single platform, enabling teams to leverage automation and AI and begin enhancing manufacturing processes immediately.