This article examines the importance of tolerance analysis in ensuring reliable assembly and controlling manufacturing costs for mechanical design. It discusses how Autodesk Inventor Tolerance Analysis integrates with CAD models so engineers can validate dimensional variation and optimize design decisions early in the workflow.

Success in product development is a function of both precision and cost-efficiency. When balancing these pressures, tolerance analysis is an engineer’s best friend. Despite its importance, tolerance analysis is often underutilized or conducted late in the design process, leading to avoidable production issues and budget overruns. By integrating tolerance analysis earlier and more directly into the CAD workflow, engineering teams can anticipate variation, validate fit, and confidently progress toward manufacturing.

Tolerance analysis in design validation

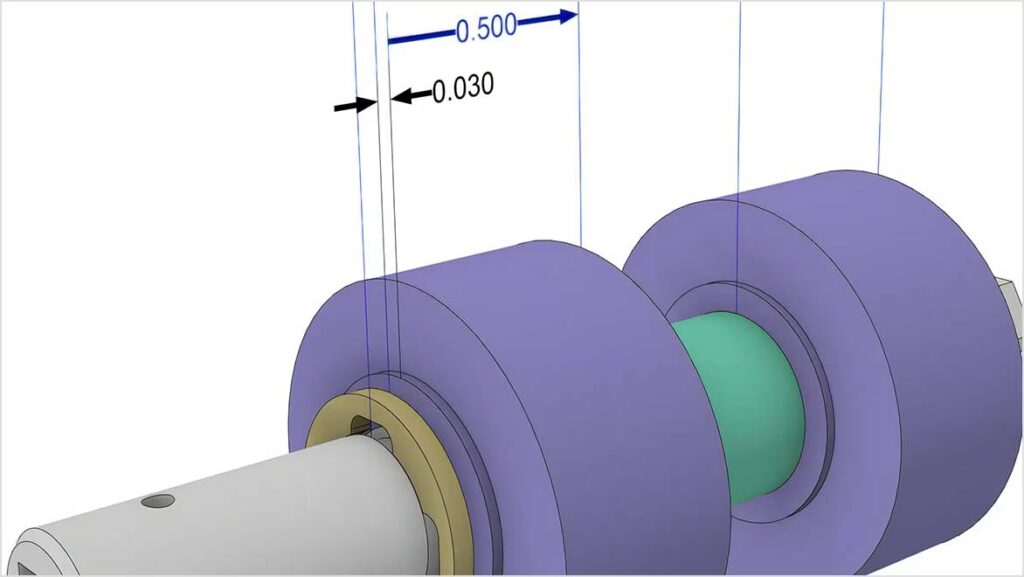

Tolerance analysis examines how slight differences in part dimensions affect the components’ ability to fit and work together in an assembly. By looking at the allowed variations, as defined by geometric dimensioning and tolerancing (GD&T) standards, engineers can understand how those differences build up across a design. This buildup is called a tolerance stack-up and predicts whether parts will assemble correctly and function reliably in real deployments.

Traditional methods of tolerance analysis are time-consuming and error-prone. While engineers have historically used spreadsheets or manual calculations, assemblies have grown so complex that these approaches are becoming insufficient. For example, they risk over-specifying tolerances to ensure fit, which can drastically increase machining costs. Or they risk under-specifying tolerances, resulting in misalignments, rework, or part rejection. In either case, product development efficiency and profitability suffer.

These days, designers have shifted toward model-based engineering, where 3D models carry important functional details, including tolerance specs. The ability to run tolerance analysis directly inside your CAD software allows engineers to see how variation might affect things much earlier in the design process, before problems get expensive to fix. With a proactive approach, engineers can uncover contributors to stack-up and guide design revisions with data-driven insights. It also supports statistical analysis methods, such as worst-case, root-sum-square (RSS), and Monte Carlo simulations, which help discern trade-offs between manufacturing capability and design intent.

Autodesk Product Design & Manufacturing Collection

Solve interesting problems efficiently with the ultimate set of engineering apps.

Learn MoreStack-up validation with Inventor Tolerance Analysis

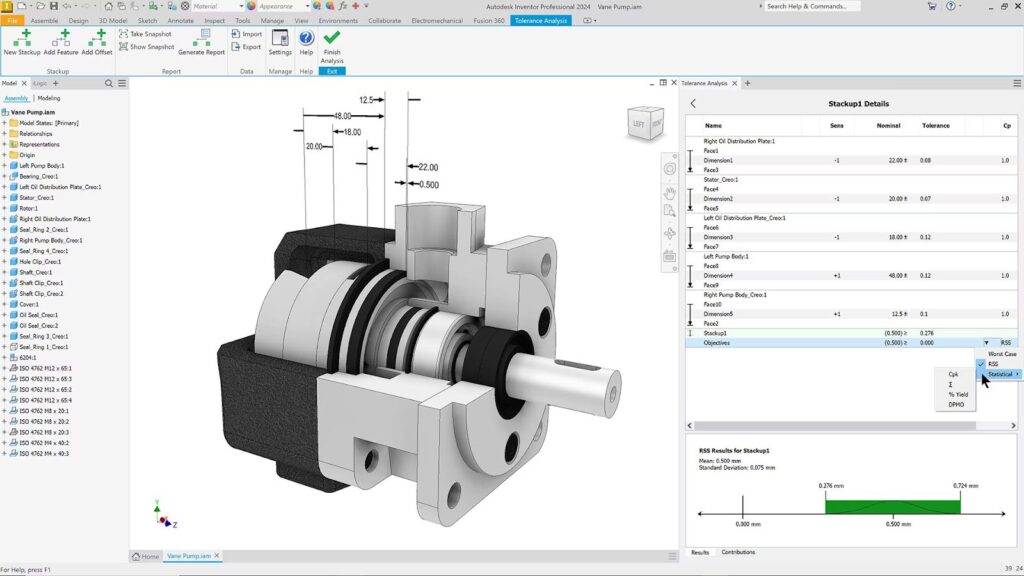

Autodesk bundles Inventor Tolerance Analysis into its Product Design & Manufacturing Collection to help aid in design verification, without breaking your workflow. The software lets users run tolerance stack-up analyses right inside Inventor, so there’s no need to export data to another program or work through calculations by hand. The workflow is also embedded and associative, meaning that when the model updates, so does the analysis. This function keeps everything synchronized and reduces the risk of oversight.

Inventor Tolerance Analysis interprets tolerance data directly from the 3D model and automatically recognizes constraints and datum references defined in the GD&T schema. Engineers can try alternate tolerancing schemes and see the assembly response change immediately. For example, they may want to loosen a hole tolerance or adjust a datum and the stack-up shifts on the spot. Using worst-case checks and statistical methods, the software reports practical quality measures (e.g., Cpk, sigma level, and DPMO) that let teams judge whether the design will meet targets before it moves into production.

One of the major advantages of Inventor Tolerance Analysis is that it can present findings in a clear, visual manner. Reports include annotated images, contributing dimension breakdowns, and summarized metrics that engineers can share with manufacturing teams or quality engineers. Cross-functional collaboration improves, and all stakeholders understand the impact of tolerance decisions on cost, fit, and performance.

The tool also integrates model-based definition (MBD) capabilities that allow users to edit tolerance values within the same interface used for analysis. In this way, Inventor streamlines the iterative design optimization process by eliminating the need to switch between platforms or manually update data. Additionally, its statistical engine supports what-if scenarios that make it easier to find the balance between design and manufacturing capability.

Better insights, better products

As mechanical assemblies get more complicated and companies face tighter budgets, keeping variation under control through solid tolerance analysis has become incredibly important. Autodesk’s Inventor Tolerance Analysis helps engineers tackle this by letting them evaluate tolerances inside the Inventor platform, using their actual models. This means they can make smarter calls about dimensions, quality targets, and cost trade-offs without jumping between different tools.