Learn more about how finite element analysis (FEA) enhances product design, safety, and cost-efficiency and how Autodesk solutions can help.

Finite element analysis (FEA) is a powerful computational tool for predicting how products react to real-world forces, vibration, heat, fluid flow, and other physical effects. It’s an important part of the design and manufacturing process, helping engineers create optimized, efficient, and safe products. Let’s take a look at what exactly FEA is, its benefits, and how Autodesk solutions can help.

Understanding Finite Element Analysis (FEA)

FEA is a numerical method that divides a complex problem into smaller, manageable parts called finite elements. These elements connect at nodes, forming a mesh that represents the entire structure. By applying known physical laws and material properties to each element, FEA can predict the behavior of the entire structure under various conditions.

The Process of FEA

- Pre-processing: In this phase, the geometry of the model is defined, and the material properties are assigned. The meshing of the model is performed, dividing it into small finite elements. Boundary conditions and loads are also specified.

- Solution: This phase involves solving the mathematical equations derived from the physical laws governing the behavior of each finite element. The solution provides data on parameters such as stress, strain, temperature, and displacement.

- Post-processing: Here, the results are analyzed and visualized. Engineers interpret these results to make informed decisions about the design and manufacturing process. They can identify areas of potential failure, optimize material usage, and improve product performance.

Benefits of FEA in Manufacturing

- Improved product design: FEA allows engineers to test and refine designs prior to physical prototyping. This leads to better-performing products and fewer costly design changes.

- Cost savings: By identifying potential issues early in the design process, FEA reduces the need for multiple prototypes and extensive physical testing. The result – saving both time and money.

- Enhanced safety: FEA helps predict how products will behave under various conditions. This aids in ensuring they meet safety standards and perform reliably in real-world applications.

- Material optimization: Engineers can use FEA to optimize material usage. This helps reduce waste and ensure that products have the most suitable materials for their intended purpose.

Autodesk Solutions for FEA in Manufacturing

Autodesk offers several powerful tools that can assist engineers and manufacturers in implementing FEA effectively.

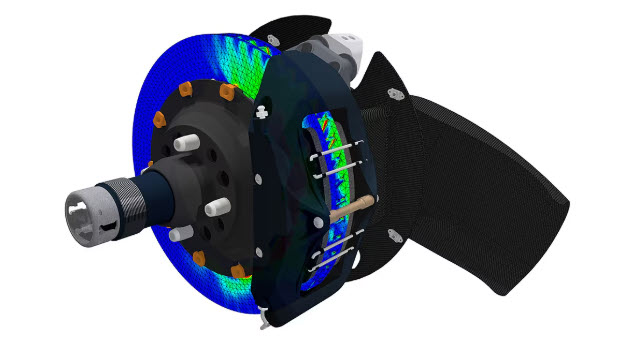

Inventor Nastran

Autodesk Inventor Nastran, part of the Product Design and Manufacturing Collection, is a powerful FEA tool. It offers extensive simulation capabilities across multiple analysis types, including linear and nonlinear stress, dynamics, and heat transfer. The integration of Nastran within Inventor allows users to perform complex simulations directly, streamlining the workflow and enhancing productivity. With features such as advanced editing, context-sensitive input, and dynamic help, Inventor Nastran provides engineers with greater control over their FEA models and results. This drive more reliable and accurate predictions of physical behavior under various boundary conditions.

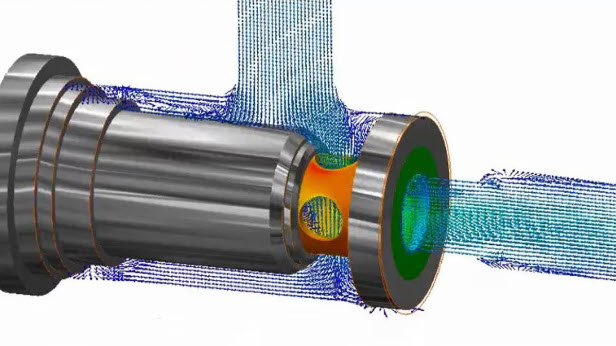

Autodesk CFD

Autodesk CFD (Computational Fluid Dynamics) offers a robust suite of simulation tools designed to analyze and predict fluid flow and heat transfer within various product designs. One of its key features is the ability to simulate both steady-state and transient fluid dynamics. This provides detailed insights into how fluids interact with surfaces and structures under different conditions. Users can leverage cloud-based solving capabilities to run simulations faster and more efficiently, to free up local computing resources for other tasks.

The software also supports advanced meshing techniques, so that complex geometries are accurately represented for precise analysis. Integrated thermal simulation capabilities allow engineers to evaluate heat transfer and thermal management solutions, crucial for optimizing performance and preventing overheating in products.

Conclusion

Finite Element Analysis (FEA) is an indispensable tool in modern manufacturing. It helps provide insights that lead to improved product design, cost savings, enhanced safety, and material optimization. By leveraging Autodesk solutions, companies can ensure that their products are meet the highest standards of performance and reliability.